Premium 22–28mm Triple Pane Glass Door Freezer Solutions: High-Performance IGU for Commercial Refrigeration

Premium 22–28mm Triple Pane Glass Door Freezer Solutions: High-Performance IGU for Commercial Refrigeration

Product: 22–28 mm Double Glass Door Freezer

Thickness: Triple Pane 4–5 mm tempered glass (≈ 7/8″–1 1/8″)

Color: Clear, Low Iron, Low E color

Size: Customized, less than 2440x3660mm

Application: window, door

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 20 square meters

Supply Ability: Over 5000 Square Meter / Day

Country of Origin: China

Lead Time: 25 Days

Payment Term: Bank Wire Transfer (T/T)

If you require more details from Xpert BM, please submit the form on the Get a Quote page or send an email to sales@xpertglazing.com and WhatsApp +86 15711964309!

Special Glass

In the competitive world of commercial food retail and cold chain logistics, the visibility and preservation of products are paramount. The glass door freezer is no longer just a storage unit; it is a critical touchpoint for consumer engagement and a significant factor in operational energy costs.

At Xpert Building Material, we specialize in supplying high-performance freezer glass solutions. Our 22–28mm Triple Pane Insulated Glass Units (IGU) represent the quality of thermal insulation technology, specifically designed for the rigorous demands of the modern commercial glass door freezer.

What is 22-28mm Triple Pane Glass for Glass Door Freezer?

When we discuss a glass front freezer, the “glass” is rarely just a single sheet. For commercial applications—where temperature differentials between the frozen interior and the humid exterior can exceed 40°C—a sophisticated multi-layered system is required.

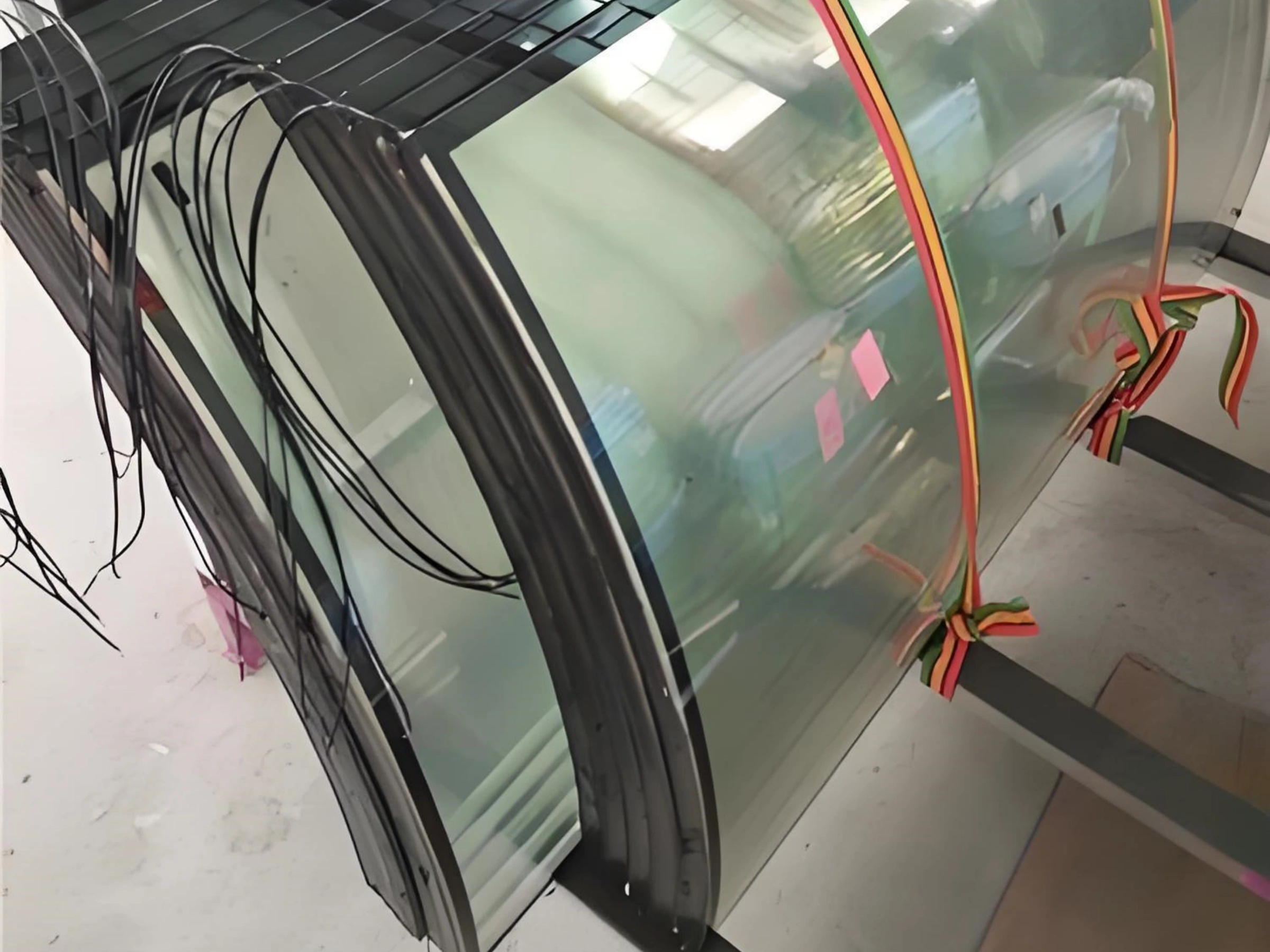

The 22–28mm Triple Pane Glass is an advanced Insulated Glass Unit (IGU) consisting of three layers of tempered safety glass separated by two hermetically sealed air or gas-filled spaces.

The Anatomy of High-Performance IGU

Outer Pane: Usually a 4mm or 5mm tempered glass, often treated with an anti-condensation coating.

Intermediate Pane: Provides an extra thermal barrier, significantly reducing the U-value (heat transfer coefficient).

Inner Pane: Frequently coated with Low-E (Low-Emissivity) materials to reflect internal cold back into the unit.

Spacer Bars: Specialized “warm edge” spacers that maintain the gap (typically 6mm to 9mm per gap) and contain desiccants to absorb moisture.

Gas Fill: The cavities are often filled with Argon or Krypton gas, which are denser than air and provide superior thermal resistance.

By choosing a 22-28mm profile, manufacturers of the triple glass door freezer ensure maximum structural integrity without adding excessive weight to the door hinges, balancing durability with ergonomic ease of use.

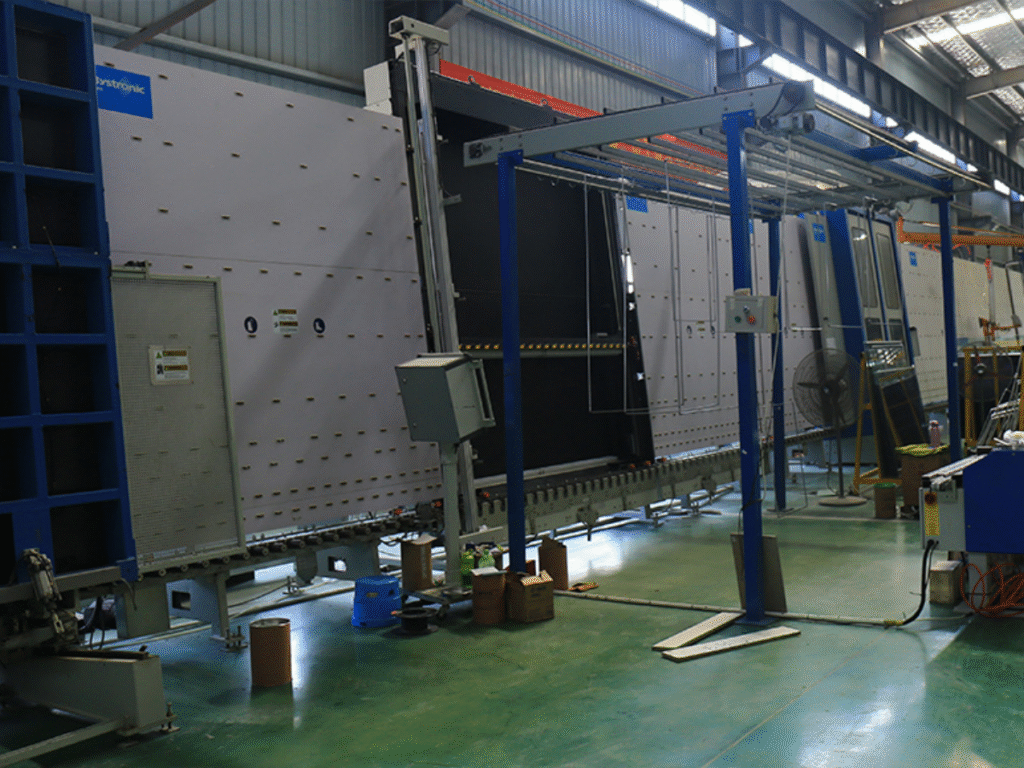

Working-Flow for Triple Pane IGU Freezer Glass

Features for 22-28mm Triple glass door freezer

Why upgrade to a triple-pane system? The advantages extend far beyond simple aesthetics.

Superior Thermal Insulation & Energy Efficiency

The primary goal of any commercial glass door freezer is to maintain a constant sub-zero environment. Our 22-28mm IGU configurations drastically reduce thermal leakage. By utilizing triple glazing, you achieve a significantly lower U-value compared to standard double glazing, leading to up to 30% reduction in compressor energy consumption.

Advanced Anti-Condensation (Heated Glass) Technology

Nothing kills a sale faster than “foggy glass.” In high-humidity environments, standard glass reaches its dew point quickly. Our freezer glass can be equipped with transparent conductive coatings (ITO). When a low-voltage electrical current passes through the glass, it generates subtle heat that keeps the surface clear 24/7, ensuring your products are always visible to the customer.

Enhanced Structural Safety

Commercial environments are high-traffic zones. Our glass is fully tempered (toughened), making it up to five times stronger than regular glass. In the rare event of breakage, it shatters into small, blunt granules rather than sharp shards, protecting both staff and customers.

UV Protection and Color Rendition

Our Low-E coatings are designed to block harmful UV rays that can degrade food quality and fade packaging, all while maintaining high visible light transmittance (VLT). This ensures that the food inside the glass front freezer looks vibrant and appetizing.

Noise Reduction

The triple-layer construction acts as an effective acoustic barrier, dampening the hum of heavy-duty commercial compressors and creating a more pleasant shopping environment for customers.

Specification 22-28mm Triple Pane Glass for Glass Door Freezer

| Feature | Specification Details | Technical Notes |

| Total Thickness | 22mm, 24mm, 26mm, 28mm (Customizable) | Optimized for standard commercial frames. |

| Glass Type | Tempered, Low-E, Heated (ITO), Silk-screened | Safety glass is standard for all layers. |

| Single Glass Thickness | 4mm / 5mm / 6mm | Combinations depend on door size. |

| Gas Filling | Air / Argon (90%+) / Krypton | Argon is the industry standard for ROI. |

| Spacer Material | Aluminum / Stainless Steel / Warm Edge (TPS) | Warm edge spacers prevent perimeter frosting. |

| U-Value | <1.1 W/(m^2 x K) (with Argon & Low-E) | Dependent on specific gas and coating. |

| Light Transmittance | >75% | Ensures crystal clear product visibility. |

| Sealant System | Primary: Butyl (PIB); Secondary: Polysulfide/Silicone | Double-sealed for 10+ years of lifespan. |

| Operating Temp | -30°C to +50°C | Ideal for deep freeze applications. |

| Certifications | CCC, CE, SGCC, IGCC, ISO9001 | Meets international safety and quality standards. |

| Frame Compatibility | PVC, Aluminum, Stainless Steel Frames | Glass is delivered ready for insertion. |

Glass Thickness by Glass Door Freezer Type

| Freezer Type | Glass Thickness |

|---|---|

| Commercial upright freezer | 22–28 mm |

| Reach-in freezer (-18°C / 0°F) | 24–28 mm |

| Display / merchandiser freezer | 25–30 mm |

| Walk-in freezer door (vision panel) | 28–40 mm |

Why Triple Pane Is Required

Maintains -18°C to -25°C internal temperature

Prevents condensation and frosting

Improves energy efficiency

Meets safety and food-service regulations

Special Features Often Included

Low-E coating (heat reflection)

Heated glass or door frame (anti-fog)

Argon gas fill (better insulation)

Tempered or laminated safety glass (mandatory)

Residential vs Commercial

Residential freezer drawers/doors: sometimes double pane (~18–22 mm)

Commercial freezers: almost always triple pane

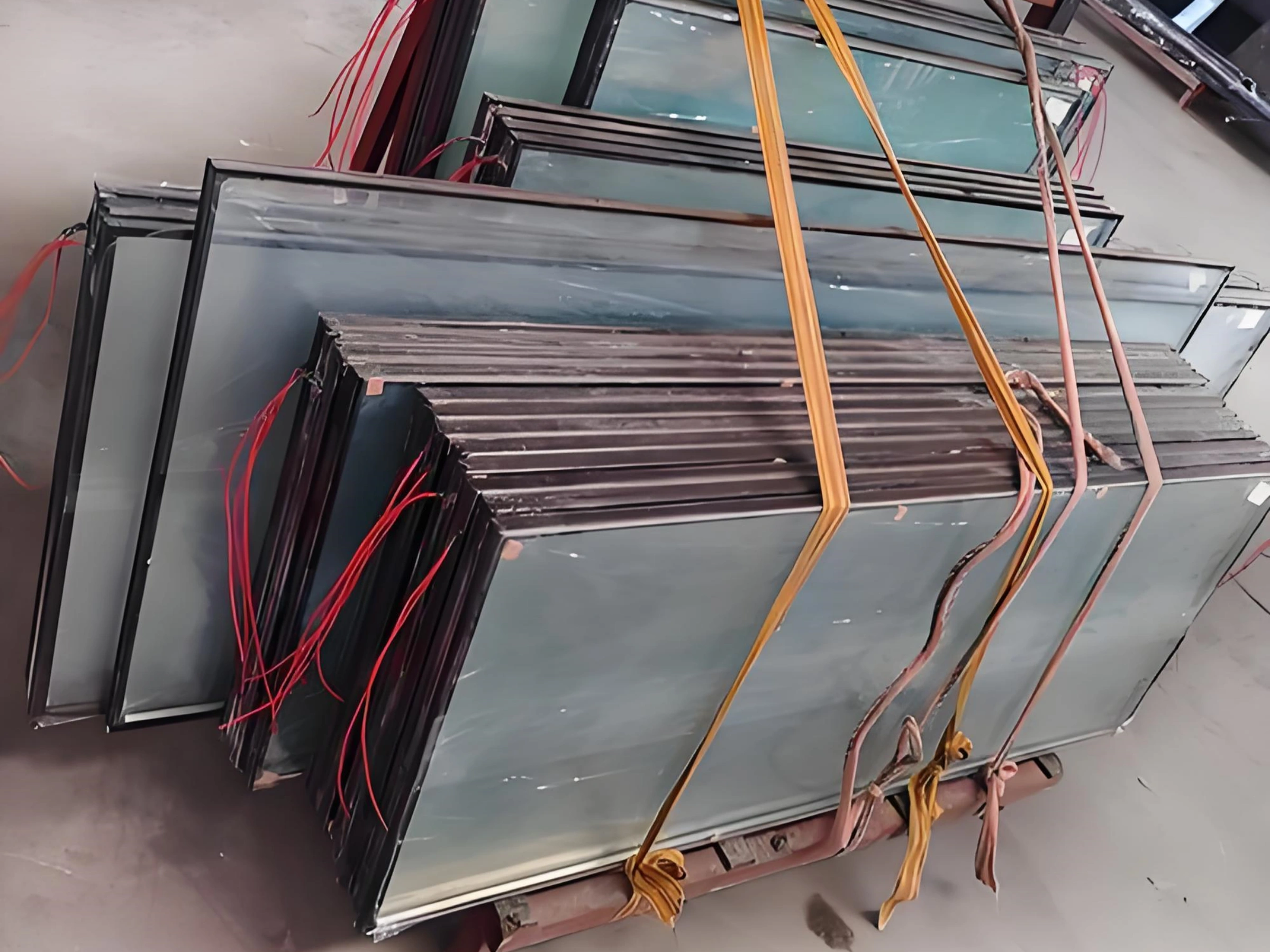

Packing Information for 22-28mm Triple Pane Glass for Glass Door Freezer

Shipping heavy, fragile freezer glass across the globe requires precision and heavy-duty protection. At Xpert Building Material, we treat logistics as an extension of our manufacturing process.

Sea-Worthy Packaging Standards

Custom Wooden Crates: We use IPPC-certified, fumigated solid wood crates or high-strength plywood crates. Each crate is custom-built to the dimensions of the glass order to prevent movement.

Interlayer Protection: Every sheet of glass is separated by cork pads, EVA pads, or high-end protective powder to prevent scratches and surface friction during transit.

Moisture Protection: The entire crate is wrapped in a moisture-proof plastic film and includes desiccant packets to prevent “glass sweating” or oxidation of Low-E coatings during sea freight.

Shock Absorption: Crates are secured within the container using steel strapping and air bags to withstand the rigors of ocean swells and port handling.

Labeling: Each crate features clear “Fragile,” “This Side Up,” and “Handle with Care” markings, along with a detailed packing list for easy customs clearance and inventory management.

Are you looking for a reliable partner for your next commercial refrigeration project? Our team is ready to provide technical consultations, CAD support, and competitive wholesale pricing for global shipping.

Contact Us for a Quote:

Company: Xpert Building Material

Email: sales@xpertglazing.com

WhatsApp: +8615711964309

Don’t settle for standard visibility. Invest in the clarity and efficiency of Xpert Glazing solutions. Reach out to us via WhatsApp or Email for a personalized consultation today!

FAQs for Order 22-28mm Triple Pane Glass for Glass Door Freezer

For a first-time cooperation, we are happy to provide free samples for simple products such as clear tempered glass and clear laminated glass to support our initial collaboration. However, we are unable to cover the shipping costs. We hope both sides can share some of the expenses from a partnership perspective. If this order and project move forward and we work together in the future, these costs can be fully deducted from our formal cooperation.

Yes, we are able to provide triple Low-E glass insulated glass units (IGUs) according to your specifications. Actually we work based on very good relationship with XYG, CSG, Jinjing, TG Glass, SYP.

Yes, we can supply replacement Low-E insulated glass units (IGUs) to match your existing specifications, including size, glass type, spacer, and Low-E coating. We can manufacture them to fit seamlessly into your current frames.

Yes, we do offer door-to-door service. We can arrange it according to your location, and the exact cost and lead time will be confirmed based on the destination and shipping method you prefer.

For tempered glass and standard laminated glass, we generally offer a 5-year warranty. For higher-performance glass, such as insulated glass, Low-E glass, and coated glass, we typically provide a 10-year warranty.

Please note: As glass is inherently fragile, there is always a risk of breakage during transportation. Even for tempered glass, despite our use of high-quality raw glass from XYG, CSG, and PPG, and processing with advanced tempering furnaces from NorthGlass and LandGlass, there is still an approximate 0.2% risk of spontaneous breakage. If any damage occurs, we will do our best to assist you in minimizing the loss.

Yes. We offer Electrically Heated Glass (ITO glass) where the inner surface of the outer pane is coated with a transparent conductive layer. This is the gold standard for commercial glass door freezer visibility.

Absolutely. We are an OEM-focused supplier. We can produce triple glass door freezer panels according to your specific CAD drawings, including holes for handles or specialized silk-screened logos.