Let's work together to turn your vision into reality. Contact us today to schedule a consultation and take the first step towards creating something amazing together. Our ultimate goal is to deliver results that exceed your expectations.

Special Glass

At Xpert BM, this mainly includes fire-resistant glass, furniture glass, appliance glass, and a range of other types of glass used in special applications. These kinds of glass are frequently used in practice and are often requested by our clients. That’s why we have integrated the supply chain in this area and partnered with manufacturers specializing in these products.

What is Fire Rate Glass?

Fire rate glass, also called fire resistance glass, sometimes mistakenly called “fire rate glass”) is a specialized glazing material designed to resist fire and high heat for a specified period of time.

Unlike ordinary glass, which shatters quickly under high temperatures, fire-rated glass is tested and certified to maintain its integrity (and in some cases insulation) during a fire, helping to prevent the spread of flames, smoke, and radiant heat through building openings.

It is commonly used in fire doors, partitions, windows, and facades in places like hospitals, schools, airports, commercial complexes, and high-rise buildings.

What is Furniture Glass?

Furniture Glass refers to specialized glass types designed for use in furniture design, either as a structural component (like a table surface) or a decorative element (like cabinet inserts). Unlike standard window glass, furniture glass is typically tempered or laminated for safety and durability.

| Thickness | Common Application | Load Capacity |

| 3mm – 4mm | Cabinet door inserts, picture frames, small mirrors. | Low |

| 6mm (1/4″) | Table covers (wood protectors), small shelves. | Medium-Low |

| 10mm (3/8″) | Frameless shower doors, heavy shelves, side tables. | Medium-High |

| 12mm (1/2″) | Structural dining tables, desks, coffee tables. | High |

| 15mm – 19mm | Luxury executive desks, heavy structural partitions. | Maximum |

What is Appliance Glass?

Appliance Glass refers to high-performance, specialized glass designed to withstand extreme thermal stress, chemical exposure, and mechanical impact. Unlike standard furniture glass, appliance glass is a functional component critical to the energy efficiency and safety of household machines like ovens, cooktops, and refrigerators.

| Glass Type | Heat Resistance | Primary Applications | Key Feature |

| Glass-Ceramic | Up to 700°C | Induction & Radiant Cooktops | Zero thermal expansion; won’t crack under ice-to-heat shock. |

| Borosilicate | Up to 450°C | Microwave trays, pyrex-style ovenware | High thermal shock resistance and chemical durability. |

| Tempered (Toughened) | Up to 250°C | Oven doors (outer/middle), Fridge shelves | 5x stronger than standard glass; breaks into safe “pebbles.” |

| Low-E Coated | Variable | Inner Oven Doors | Reflects heat back into the cavity to keep the outer door cool. |

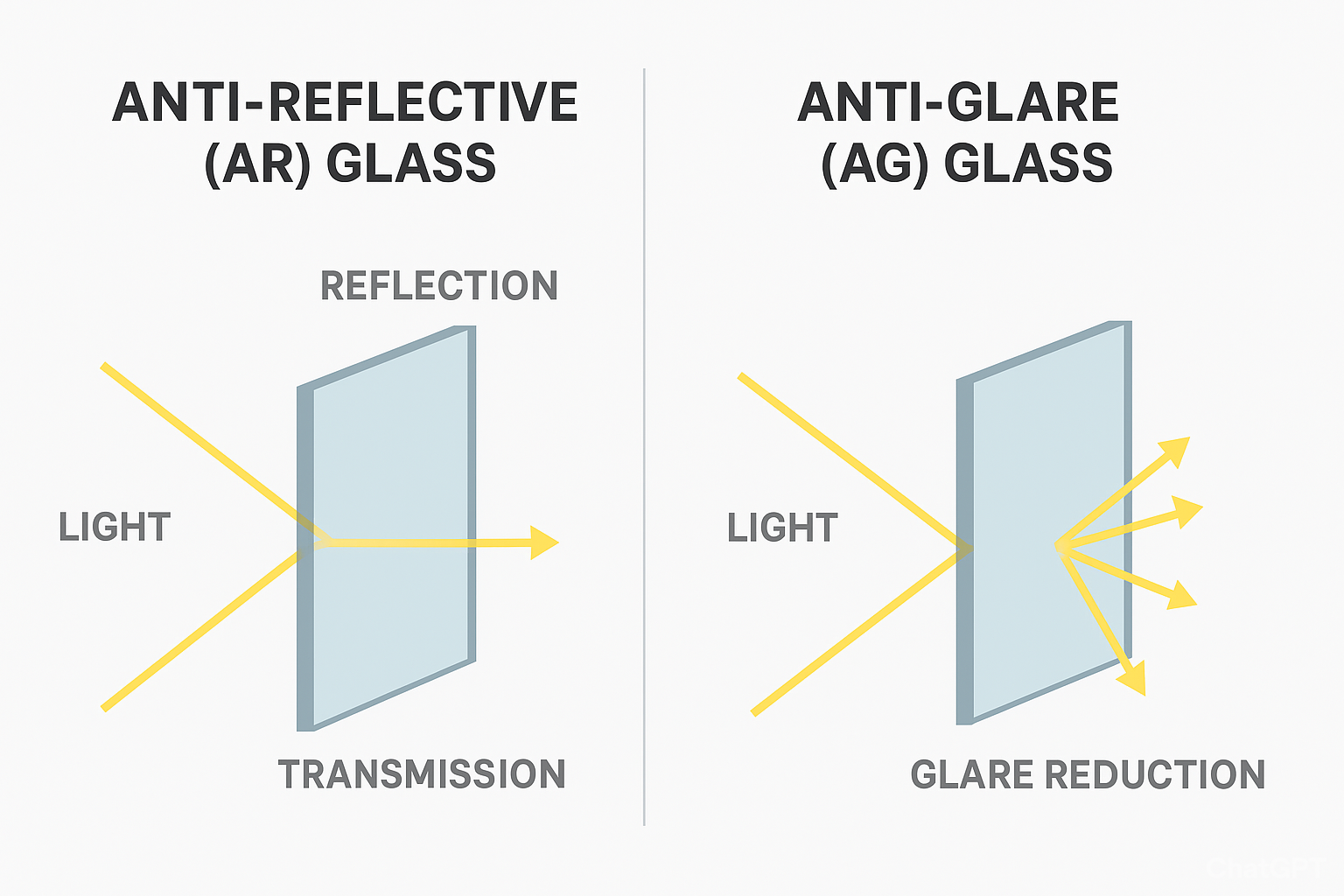

AR Glass AG Glass

🔹 Difference Between AR Glass & AG Glass

| Feature | Anti-Reflective (AR) Glass | Anti-Glare (AG) Glass |

|---|---|---|

| Function | Reduces reflection by optical coating (interference effect) | Reduces glare by scattering light with matte surface |

| Mechanism | Thin-film coating with low refractive index | Acid-etching or coating roughens surface |

| Light Transmission | Very high (up to 97–99%) | Slightly lower (90–95%) |

| Surface Finish | Smooth, clear, glossy | Matte, satin-like |

| Viewing Quality | High clarity, colors accurate, no distortion | Reduced sharpness (slight diffusion) but easier on eyes |

| Best Use Cases | Museums, galleries, solar panels, high-end displays, lenses | Tablets, kiosks, monitors, ATMs, photo frames in bright light |

| Cost | Higher (complex multilayer coating) | Lower (acid etching is simpler) |