Exceptional 12+12mm Laminated Glass Frameless Curtain Wall System-High Light Transmittance Modern Aesthetics

Exceptional 12+12mm Laminated Glass Frameless Curtain Wall System-High Light Transmittance Modern Aesthetics

Product Name: 12+12mm Laminated Glass Frameless Curtain Wall System

Application: Commercial building/shopping mall/plaza/office building/headquarters building/public places

Frame: Laminated Glass/ IGUs + Glass fin (8+8+8mm, 10+10+10mm)

Customize: Acceptable according to the drawing.

Product description: Glass Curtain Wall Design, Glass curtain wall Suppliers Directory – Find a variety of curtain wall spider system Suppliers, Manufacturers, Companies from China.

Contact us if you need more information – sales@xpertglazing.com, or WhatsApp +8615711964309

Glass Frameless Curtain Wall System

In the realm of contemporary architecture, the boundary between the interior sanctuary and the exterior world is blurring. The drive for “transparency” has moved beyond a design trend to a structural requirement. At the forefront of this evolution is the frameless curtain wall, a solution that offers unparalleled panoramic views without the visual interruption of bulky metal frames.

Specifically, the 12+12mm laminated glass frameless curtain wall system represents the pinnacle of safety, clarity, and structural integrity. By utilizing high-strength point-supported hardware and glass fin reinforcements, this system allows architects to push the limits of vertical glazing.

What is Glass Frameless Curtain Wall System?

The frameless glass curtain wall is a lightweight, non-load-bearing exterior building envelope that utilizes point-fixing components or glass fins to support large-format glass panels. Unlike traditional stick-built systems that rely on aluminum mullions and transoms, the frameless system prioritizes the “all-glass” look.

The core of this system often relies on the curtain wall spider system. These stainless steel “spiders” act as the mechanical link, gripping the glass panes at their corners and transferring wind loads and dead loads to the building’s main structure or a secondary support system (like glass fins or steel trusses).

The 12+12mm Advantage

When we talk about 12+12mm laminated glass, we are referring to two layers of 12mm tempered (toughened) glass bonded together by a high-performance interlayer, typically PVB (Polyvinyl Butyral) or SGP (SentryGlas Plus). This configuration is the “gold standard” for high-traffic commercial facades and high-rise lobbies because it provides:

Structural Redundancy: Even if one pane breaks, the interlayer holds the fragments in place.

Massive Span Capability: The thickness allows for taller spans without excessive deflection.

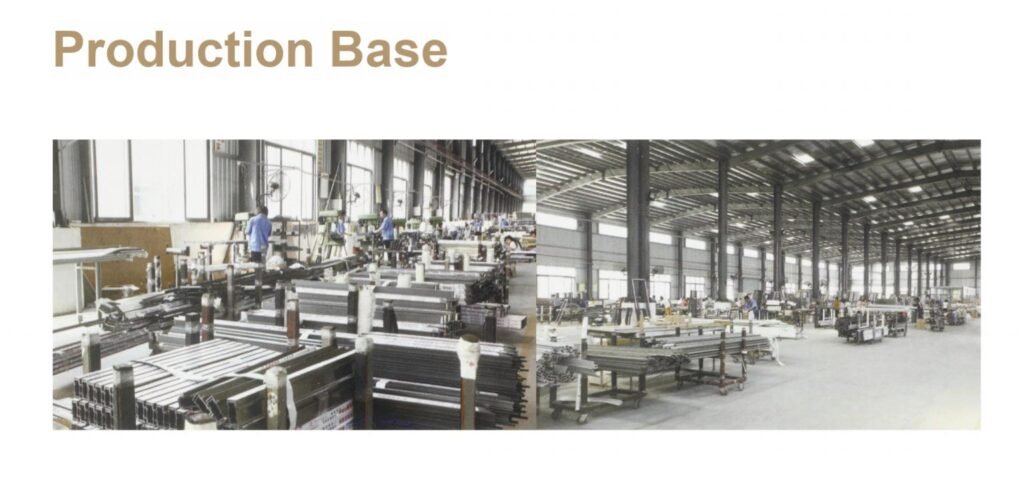

At Xpert Building Material (Xpert BM), we believe that a high-performance frameless curtain wall starts on the factory floor.

Precision CNC Processing

The holes for a spider glass curtain wall must be accurate to within 0.5mm. Our automated CNC drilling and milling centers ensure that every point-fixed connection aligns perfectly during site installation, preventing stress concentrations on the glass.

Advanced Laminating Cleanrooms

Laminated glass is sensitive to humidity and dust. Our 12+12mm panels are assembled in a Class 1000 cleanroom environment to prevent delamination and ensure crystal-clear optics. We utilize high-pressure autoclaves to guarantee a permanent bond between the glass and the interlayer.

Rigorous Quality Control (QC)

Every panel undergoes a series of tests:

Fragment Test: Ensuring the tempering pattern meets safety standards.

Heat Soak Testing (HST): To eliminate the risk of spontaneous breakage due to Nickel Sulfide (NiS) inclusions.

Optical Distortion Analysis: Ensuring the view remains true and undistorted at any angle.

Features for Frameless Glass Curtain Wall

Choosing a spider glass curtain wall is an investment in both form and function. Here are the defining features that make our 12+12mm system stand out:

Maximum Transparency and Natural Light

By eliminating opaque framing members, the frameless curtain wall increases visible light transmittance (VLT). This reduces the need for artificial lighting and enhances the well-being of occupants by providing a constant connection to the outdoors.

Superior Modern Aesthetics

The “seamless” look is a hallmark of premium commercial real estate. Whether it’s a luxury car showroom, a corporate headquarters, or a museum, the frameless glass curtain wall provides a sleek, high-tech finish that increases the property’s market value.

Acoustic and Thermal Performance

While glass is often perceived as a “cold” material, our 12+12mm laminated units, when combined with Low-E coatings or argon-filled insulated layers, provide excellent sound dampening (STC ratings) and thermal insulation (low U-values).

Engineering Resilience

Our systems are engineered to withstand extreme wind pressures, seismic activity, and thermal expansion. The curtain wall spider system allows for articulated movement, meaning the glass can “breathe” and flex under load without cracking.

More details for frameless curtain wall system, check below you will get more info:

| Parameter | Specification Details |

| Glass Type | Double-tempered Laminated Glass (Clear, Extra Clear/Low-Iron, Tinted, Reflective) |

| Glass Configuration | 12mm + 1.52/2.28 PVB/SGP + 12mm |

| Interlayer Material | PVB (Standard) or SGP (High-Strength Ionoplast) |

| Support System | Glass Fin Curtain Wall or Stainless Steel Truss |

| Hardware Material | Grade 304 or 316 Stainless Steel (Mirror or Satin Finish) |

| Spider Fittings | 1-arm, 2-arm, 3-arm, or 4-arm heavy-duty spiders |

| Hole Processing | CNC drilled countersunk or cylindrical holes |

| Max Panel Size | Customized, Jumbo Sizes Available |

| Wind Load Resistance | Up to 5.0 kPa (Project Specific Engineering) |

| Air/Water Infiltration | High-grade structural silicone sealant application |

| Certifications | ISO 9001, CE (EN12150), SGCC, AS/NZS 2208 |

Different Glass Choices with Frameless Curtain Wall Systems

High Safety Packaging and Loading for Glass Frameless Curtain Wall

Shipping 12+12mm laminated glass curtain wall system—which is incredibly heavy—requires more than just standard crates. At Xpert BM, we have perfected the art of “Logistics for Fragile Giants.”

Custom-Built End-Cap Crates: We use heat-treated, fumigated solid wood or plywood crates designed specifically for the dimensions of your glass.

Shock Absorption: Every pane is separated by soft cork pads or anti-mildew powder, and the entire bundle is cushioned with EPE foam to absorb vibrations during sea transit.

Steel Strapping & Bracing: We use heavy-duty steel bands and internal timber bracing to ensure the load does not shift within the container.

Open-Top or Flat-Rack Loading: For jumbo-sized panels used in glass fin curtain walls, we utilize specialized containers and crane-loading techniques to ensure safe arrival.

At Xpert Building Material, we don’t just sell glass; we provide structural transparency solutions that redefine skylines. Our 12+12mm laminated frameless curtain wall systems are the choice of discerning architects and developers worldwide who refuse to compromise on safety or aesthetics.

Whether you are designing a boutique retail storefront or a massive commercial atrium, our engineering team is ready to assist you with wind load calculations, hardware selection, and shop drawings.

Contact Us Today for a Quote & Technical Consultation:

Company: Xpert Building Material (Xpert BM)

Expert Guidance: Let us help you navigate the complexities of spider glass curtain wall engineering.

Email: sales@xpertglazing.com

WhatsApp/Mobile: +86 15711964309

Transform your vision into a crystal-clear reality. Reach out to Xpert BM—where engineering meets elegance.

FAQs for Order High Safety Frameless Curtain Wall

As this is offered as a complete solution, should you require the glass and accessories to be shipped together, the related shipping costs will need to be borne by you. That said, for future official cooperation, we are open to discussing the deduction of the sample fee from your subsequent orders.

Alternatively, if you only require the accessories for reference, you will only be responsible for the freight charges.

Yes, we do offer door-to-door service. We can arrange it according to your location, and the exact cost and lead time will be confirmed based on the destination and shipping method you prefer.

The glass comes with a 5-year warranty, while the accessories are covered for 5-10 years depending on the specific product. Please note that the warranty period simply refers to the coverage we provide—it does not mean that our products will fail after 5 or 10 years.

Safety is the primary reason. While 19mm glass is strong, if it breaks, it falls in large chunks (if not tempered) or small granules (if tempered). Laminated 12+12mm glass stays adhered to the interlayer, maintaining the envelope of the building until it can be replaced.

Yes. Xpert BM provides a “Turnkey Solution.” We supply the 12+12mm glass and the compatible curtain wall spider system hardware to ensure a perfect fit and finish.

By using Low-E (low-emissivity) coatings on the #2 or #3 surface of the lamination, or by creating a laminated-insulated glass unit (e.g., 12mm + 12mm Air + 12mm), we can achieve exceptional thermal performance suitable for any climate.

Absolutely. When used with SGP interlayers, our frameless glass curtain wall systems meet the strict “large missile impact” requirements for hurricane zones like Florida or the Caribbean.