China 2025 Advanced Unitized Curtain Wall System for High-Rise Building Decoration-Installing Time-Saving and Efficient

China 2025 Advanced Unitized Curtain Wall System for High-Rise Building Decoration-Installing Time-Saving and Efficient

Product Name: High Performance Unitized Curtain Wall System

Application: Commercial building/shopping mall/plaza/office building/headquarters building/public places

Frame: Aluminum alloy with glass

Customize: Acceptable according to the drawing.

Product description: Aluminum Curtain Wall Design, Glass curtain wall Suppliers Directory – Find a variety of Aluminum Fram Curtain Wall Suppliers, Manufacturers, Companies from China.

Contact us if you need more information – sales@xpertglazing.com, or WhatsApp +8615711964309

Glass Aluminum Curtain Wall System

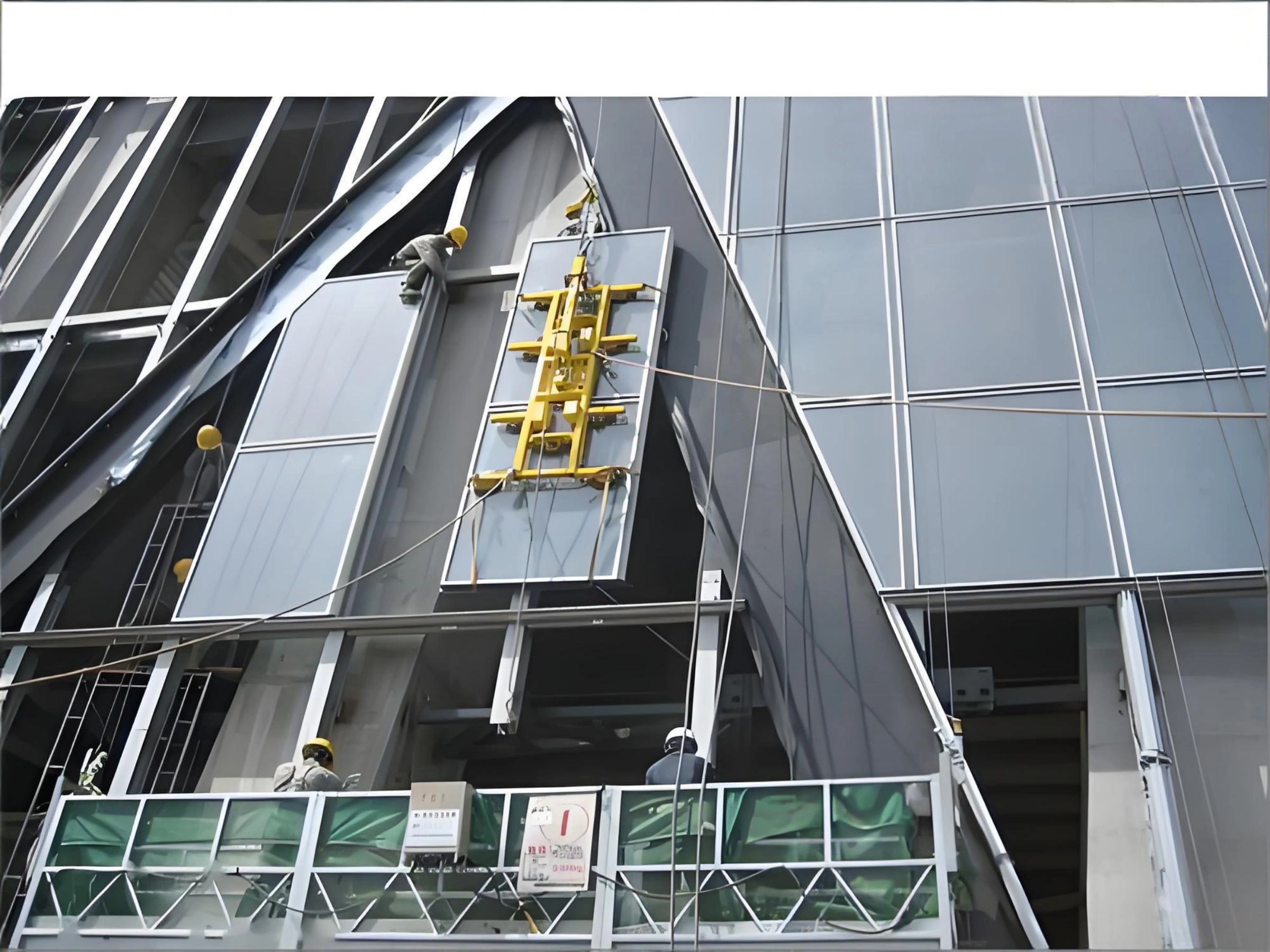

In the rapidly evolving skyline of 2025, the demand for speed, precision, and sustainability in high-rise construction has never been higher. As urban centers reach new heights, the traditional “stick” methods of facade installation are being phased out in favor of more sophisticated, factory-controlled solutions. The unitized curtain wall system has emerged as the gold standard for modern skyscrapers, offering an unparalleled blend of aesthetic flexibility and engineering excellence.

At Xpert Building Material (Xpert BM), we specialize in delivering high-performance aluminium curtain wall systems that redefine the building envelope. By shifting the complexity of construction from the windy heights of a job site to the controlled environment of our production base, we ensure that every panel meets rigorous international standards while significantly slashing installation timelines.

What is High Performance Unitized Curtain Wall System?

The unitized curtain wall system is a modular facade solution where the primary structural components—the aluminum frame curtain wall, glazing panels, and spandrel materials—are pre-assembled and glazed within a factory setting. Unlike traditional stick systems where components are installed piece-by-piece on-site, unitized panels are transported to the site as large, finished units.

These units, typically one story tall and one module wide, are hoisted into place and anchored to the building’s floor slabs. This “Lego-like” assembly process allows for:

Rapid Building Enclosure: Allowing interior trades to begin work months earlier than traditional methods.

Superior Quality Control: Every seal and gasket is applied in a dust-free, climate-controlled factory.

Exceptional Movement Accommodation: Designed to handle thermal expansion, seismic shifts, and high-wind pressures typical of super-tall structures.

The unitised curtain wall system (as it is often referred to in British and European markets) represents the pinnacle of facade engineering, integrating thermal breaks, drainage paths, and structural integrity into a single, sleek package.

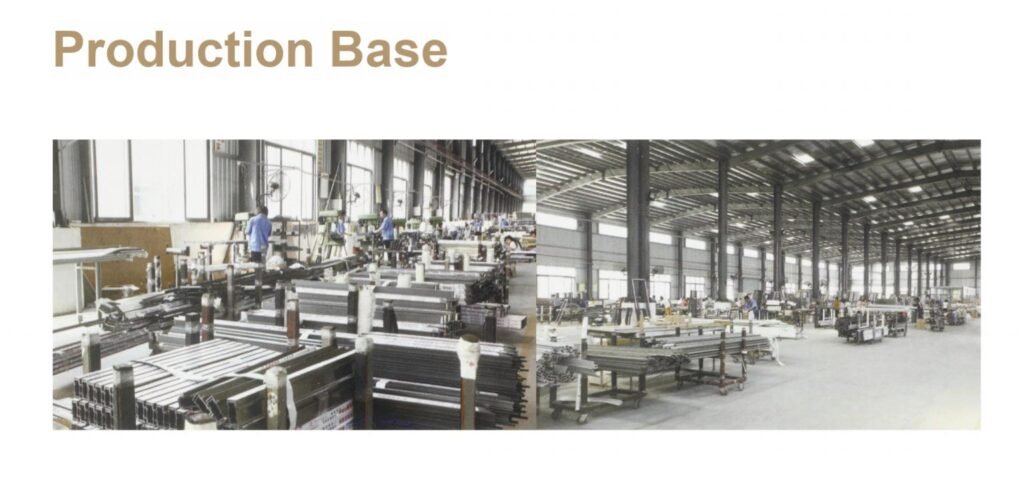

The quality of an aluminium curtain wall systems is determined long before it reaches the construction site. At Xpert BM, our production base is a center of excellence, combining automated technology with rigorous quality control.

We cooperate with China Advanced Manufacturing Facilities

The facility spans over 50,000 square meters, equipped with state-of-the-art CNC machining centers. This allows for:

High-Precision Cutting: Ensuring every mullion and transom is cut to a tolerance of within 0.5mm.

Automated Assembly: Reducing human error in the application of thermal breaks and gaskets.

Strict QC Testing: Every batch of the aluminum curtain wall system undergoes rigorous testing for structural integrity, finish thickness, and alignment.

Taking pride in “Green Factory” initiative. We utilize recycled aluminum where possible and our painting lines are equipped with VOC (Volatile Organic Compound) recovery systems. Our production processes comply with ISO 9001, CE, and ASTM standards, ensuring that your project meets international building codes regardless of location.

Features for Safety Glass Unitized Wall System

When designing a glass unitized wall system, safety and performance are non-negotiable. Our 2025 models incorporate advanced materials to ensure long-term durability and occupant comfort.

A. Advanced Thermal and Acoustic Insulation

Our systems utilize high-performance thermal breaks (polyamide strips) that decouple the exterior and interior aluminum profiles. When paired with triple-glazed Low-E safety glass, the system achieves industry-leading U-values, significantly reducing the carbon footprint of high-rise buildings.

B. Structural Integrity and Seismic Resistance

High-rise buildings are subject to immense lateral loads. Our aluminum frame curtain wall is engineered with interlocking “male” and “female” mullions. This design creates a flexible joint that allows the building to sway during seismic events or high winds without compromising the air or water seal.

C. Enhanced Safety Glazing

Safety is at the core of our glass unitized wall system. We utilize:

Tempered Glass: Four to five times stronger than standard glass.

Laminated Glass: Featuring PVB or SGP interlayers that hold glass fragments in place if breakage occurs.

Heat-Soaked Testing: To virtually eliminate the risk of spontaneous combustion due to nickel sulfide inclusions.

D. Intelligent Weatherproofing

Utilizing the principle of “Pressure Equalization,” our units are designed with internal drainage tracks. Any water that bypasses the outer gasket is collected and wept back to the exterior, ensuring the building remains bone-dry even in tropical storm conditions.

More details for unitised curtain wall system, check below you will get more info:

| Parameter | Specification Details |

| Main Framework | High-grade 6063-T5/T6 Architectural Aluminium Alloy |

| System Type | Fully Unitized, Pre-assembled Modular Facade |

| Profile Depth | 140mm, 160mm, 180mm, to 250mm (Customizable) |

| Glass Configuration | 6mm + 12Ar + 6mm / 8mm + 16Ar + 8mm (Double/Triple/ laminated) |

| Glass Coatings | Double/Triple Silver Low-E, Reflective, Fritted, Tinted |

| Surface Treatment | PVDF Coating (2/3 Coats), Powder Coating, Anodized |

| Wind Pressure | Up to 8.0 kPa (depending on engineering) |

| Water Penetration | 1000 Pa (Static & Dynamic) |

| Air Infiltration | ≤ 0.06 L/s·m² at 75 Pa |

| Thermal Performance | U-value down to 1.1 W/m²K (Triple Glazed) |

| Acoustic Rating | Rw up to 48 dB (with laminated glass) |

| Seismic Movement | Displacement up to 3% of floor height |

| Gaskets & Seals | EPDM or Silicone-based high-performance extrusions |

| Structural Silicone | Dow Corning or Sika High-Modulus Adhesive |

Different Glass Choices with Unitized Aluminium Curtain Wall Systems

High Safety Packaging and Loading for Unitized Aluminum Frame Curtain Wall

Shipping large, heavy, and fragile unitized curtain wall system panels across the ocean requires more than just a standard container. At Xpert BM, we have perfected the art of “Logistics Engineering.”

Steel A-Frame Racking

Units are loaded onto custom-engineered steel A-frames. These frames hold the panels at a slight angle, utilizing gravity to keep them secure and preventing the glass-to-glass contact that causes breakage.

Multi-Layer Protection

PE Protective Film: Applied to all aluminum surfaces to prevent scratches.

Corner Guards: High-impact plastic or foam guards protect the most vulnerable parts of the unit.

Desiccant Packs: Placed within the packaging to absorb moisture and prevent oxidation during long sea voyages.

Optimized Container Loading

We utilize Open-Top or High-Cube containers depending on unit size. Our loading teams use specialized cranes to ensure panels are packed tightly to prevent shifting, yet remain easy for your site team to unload using a “forklift-and-sling” method.

Partner with Xpert BM for Your Next Landmark Project

The facade is the face of your building. Entrust it to a partner who understands that every millimeter matters. Xpert Building Material is ready to transform your architectural blueprints into a high-performance reality.

From the initial design consultation to the final container delivery, we provide a seamless experience that prioritizes safety, efficiency, and stunning aesthetics. Let us help you build the future with the most advanced unitized curtain wall system on the market.

Get a Quote & Technical Consultation Today:

Company: Xpert Building Material (Xpert BM)

Email: sales@xpertglazing.com

WhatsApp: +8615711964309

Website: Talk to our experts about your specific wind-load and thermal requirements.

FAQs for Order High Performance Unitized Curtain Wall System

As this is offered as a complete solution, should you require the glass and accessories to be shipped together, the related shipping costs will need to be borne by you. That said, for future official cooperation, we are open to discussing the deduction of the sample fee from your subsequent orders.

Alternatively, if you only require the accessories for reference, you will only be responsible for the freight charges.

Yes, we do offer door-to-door service. We can arrange it according to your location, and the exact cost and lead time will be confirmed based on the destination and shipping method you prefer.

The glass comes with a 5-year warranty, while the accessories are covered for 5-10 years depending on the specific product. Please note that the warranty period simply refers to the coverage we provide—it does not mean that our products will fail after 5 or 10 years.

While the material cost of a unitized curtain wall system is generally 15-20% higher than a stick system due to factory labor and higher aluminum content, the total project cost is often lower. This is due to the 50-70% reduction in on-site installation time and the removal of the need for external scaffolding.

Typically, the design and shop drawing phase takes 5-7 weeks. Production starts after sample approval, with the first containers ready for shipment within 11-13 weeks.

We primarily focus on design and supply. However, we can send a team of technical supervisors to your site to train your local labor force on the correct handling and installation of our panels.

Standard units are roughly 1.5m wide by 4.0m high. However, we can manufacture “jumbo” units up to 3.0m wide or 6.0m high, depending on shipping constraints.

Our systems are designed for “easy-glazing.” If a panel breaks, it can be replaced from the interior of the building or via a BMU (Building Maintenance Unit) without needing to dismantle the entire frame.