Amazing Design 8+8mm 886 Bent Toughened Laminated Glass, Reliable Custom Curved Glass Supplier

Amazing Design 8+8mm 886 Bent Toughened Laminated Glass, Reliable Custom Curved Glass Supplier

Product: Amazing Design 8+8mm 886 Bent Toughened Laminated Glass

Thickness: 8+8mm, 18.28mm, 5/8 inch

Color: Clear, low iron, tinted, PVB color

Size: maximum reach 2440x5000mm

Application: Partitions, exterior wall, balustrade, staircase

Sample: Available, 300x600mm standard size

Delivery Term: FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: FCL for standard size, customized 20 square meters

Supply Ability: Over 5000 Square Meter / Day

Country of Origin: China

Lead Time: 20-25 Days

Payment Term: Bank Wire Transfer

Contact us right now, you will get more details of this, sales@xpertglazing.com, whatsapp: +86 15711964309

Laminated Safety Glass

In the dynamic world of modern architecture and design, the demand for innovative, safe, and aesthetically pleasing materials is constantly evolving. Among these, 8+8mm Bent Toughened Laminated Glass stands out as a premium choice, offering unparalleled safety, strength, and design flexibility.

At Xpert BM, we pride ourselves on being a leading custom curved glass supplier, delivering precisely engineered solutions tailored to your unique vision.

What is 886 Bent Toughened Laminated Glass?

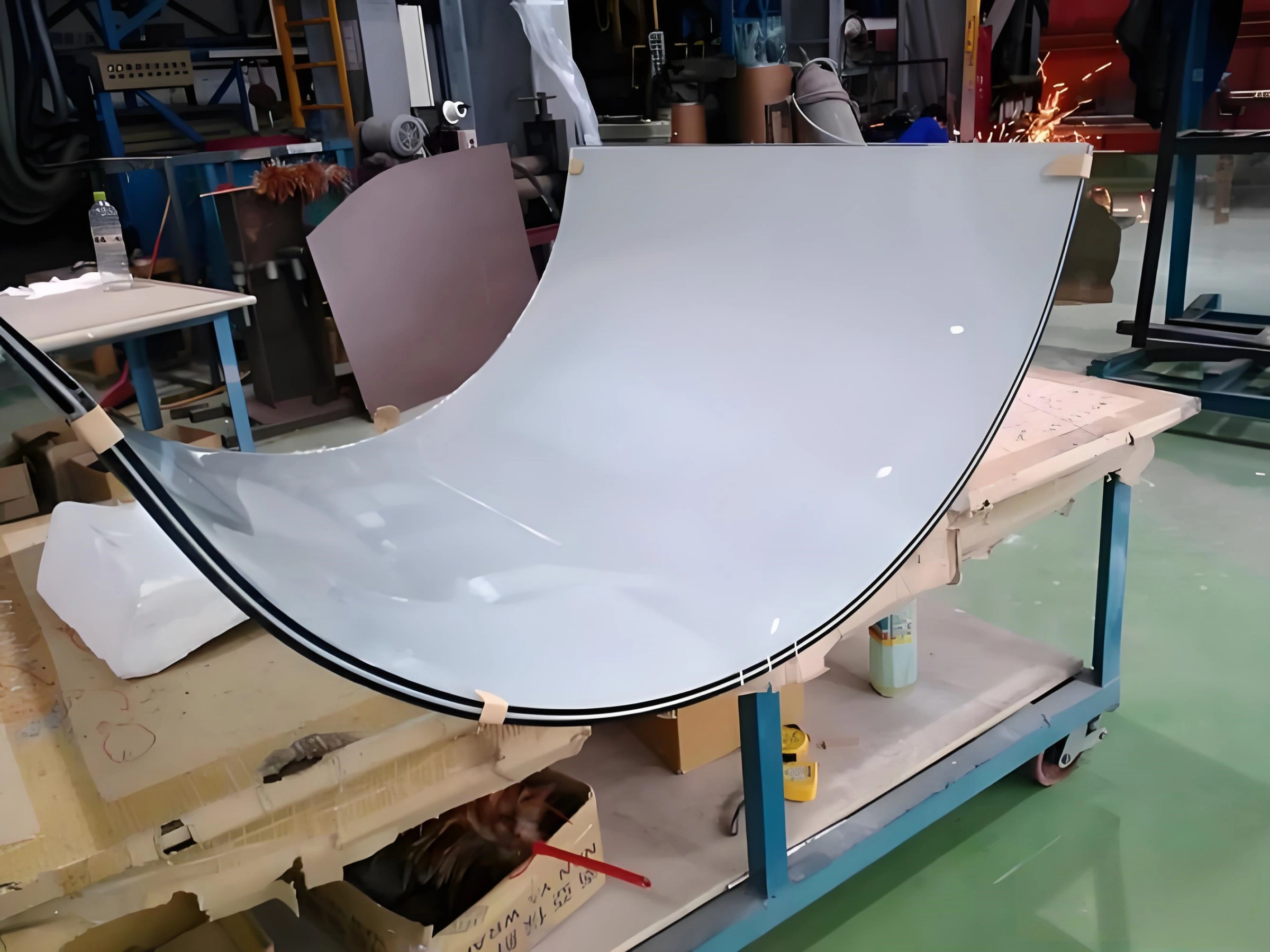

At its core, 886 Bent Toughened Laminated Glass is a sophisticated safety glass product designed for applications where both strength and a captivating aesthetic curve are paramount. It is constructed by permanently bonding two individual 8mm sheets of toughened (tempered) glass together with an advanced interlayer, typically PVB (polyvinyl butyral) or SGP (SentryGlas Plus).

This lamination process occurs after the glass has been precisely bent into the desired curvature through a meticulous hot-bending technique.

Toughened means each 8mm pane has undergone a controlled thermal treatment, making it significantly stronger than ordinary glass and, crucially, causing it to shatter into small, relatively harmless fragments if broken. The laminated ensures that, even if both glass panes break, the fragments remain firmly adhered to the interlayer, preventing dangerous shards from scattering. This combination creates an exceptionally robust and safe glass solution, perfect for high-impact or overhead applications.

Arc Length 500mm X Height 2440mm | R>200mm, thickness limit 3mm, 4mm, 5mm |

Arc Length 1600mm X Height 3300mm | R>600mm |

Arc Length 7000mm X Height 3300mm | 3000mm Arc Length, Radius>1500mm,7000mm Arc Length, Radius>3000mm |

Arc Length 3000mm X Height 7000mm | Convex – Radius>1500mm,Concave – Radius>1800mm |

Arc Length 2800mm X Height 7000mm | Multi-curved glass, to be confirmed |

Arc Length 3000mm X Height 130000mm | R>1200mm |

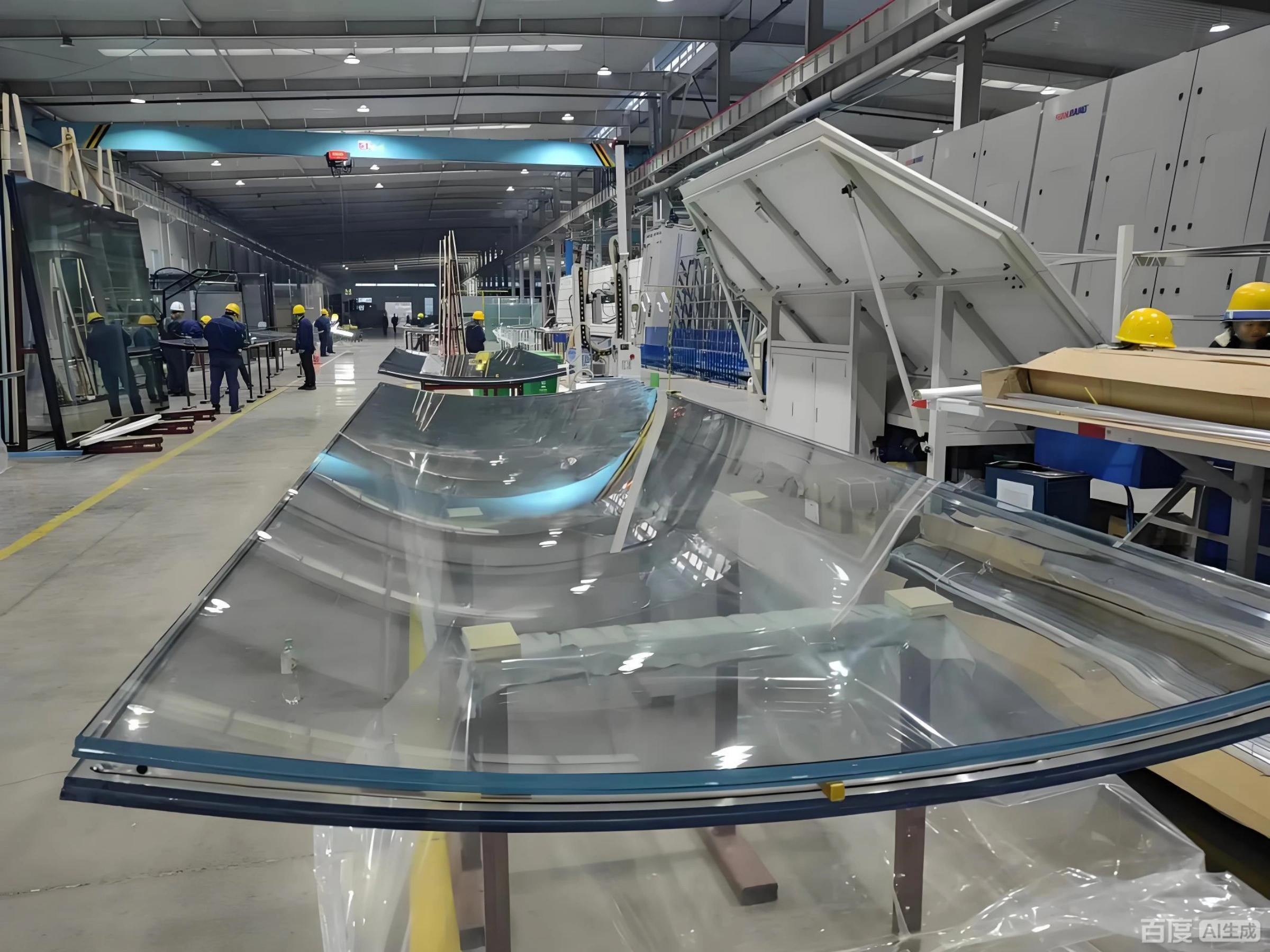

Processing Flow for 886 Bent Toughened Laminated Glass Supplier

Features of 8+2.28++8mm Laminated Hot Bending Glass

- Superior Safety & Security: The laminated security glass structure with a strong 2.28mm interlayer (often PVB or SGP) ensures that shattered glass fragments adhere to the interlayer, significantly reducing injury risk. This makes it ideal for balustrades, overhead glazing, and public spaces.

- Enhanced Structural Integrity: Toughened glass is inherently stronger than annealed glass. When laminated, it creates an incredibly resilient panel, capable of withstanding significant loads and impacts, including wind pressure and accidental collisions.

- Exceptional Design Flexibility: The hot-bending process allows for a wide array of curves, from gentle arcs to dramatic radii, opening up limitless architectural possibilities for facades, skylights, partitions, and artistic installations.

- Advanced UV Protection: The interlayer material often provides excellent UV filtration, protecting interior furnishings, artwork, and occupants from harmful ultraviolet rays, thereby preventing fading and degradation.

- Excellent Sound Attenuation: The layered construction, especially with a thicker interlayer, significantly improves acoustic insulation, reducing noise transmission and creating quieter indoor environments.

- Thermal Performance: When combined with appropriate coatings or low-emissivity (Low-E) treatments, these panels can contribute to improved thermal efficiency, helping to regulate indoor temperatures and reduce energy consumption.

- Durability & Longevity: Built to withstand the elements and daily wear, this glass type offers long-term performance and retains its aesthetic appeal for years.

Specification for 18.28mm Custom Curved Glass

| Feature | Specification |

|---|---|

| Product Type | Bent Toughened Laminated Glass |

| Total Thickness | 18.28mm |

| Glass Composition | 8mm Toughened Glass + 2.28mm Interlayer + 8mm Toughened Glass |

| Glass Type | Clear Float Glass, Ultra Clear (Low Iron) Glass, Tinted Glass (Bronze, Grey, Green, Blue) |

| Interlayer Type | PVB (Polyvinyl Butyral) or SGP (SentryGlas Plus) |

| Interlayer Thickness | 2.28mm (Standard; other thicknesses available upon request) |

| Minimum Radius | Customizable, typically from 500mm (depends on glass thickness, type, and dimensions) |

| Maximum Size (WxH) | Up to 5000mm x 2400mm, subject to specific curve and project requirements |

| Processing Technology | Hot Bending, Tempering, Lamination |

| Edge Work Options | Polished Edges (flat polished, pencil polished), Seamed Edges |

| Holes/Cut-outs | Available for fittings, hinges, or specific design elements (must be specified prior to tempering) |

| Surface Treatments | Anti-reflective coatings, Low-E coatings, ceramic frit patterns (upon request) |

| Applications | Architectural Facades, Skylights, Canopies, Balustrades, Shower Enclosures, Curved Walls, Shopfronts, Elevators, Atria |

| Compliance Standards | AS/NZS 2208:1996, EN 14449, ASTM C1172, SGCC Certified (or equivalent regional standards) |

Different 8+8mm Bent Toughened Laminated Glass Types

How Many Laminated Curved Glass Panel 886 Thick Glass Types You Can Find From Xpert BM?

At Xpert BM, we understand that every project is unique. Our expertise extends beyond standard offerings to provide a diverse range of laminated curved safety glass panel 886 (referring to 8mm+8mm with a 6-digit interlayer, typically 2.28mm or 1.52mm depending on regional standards for total thickness) options. While the “886” designation typically implies a substantial interlayer like 2.28mm, our capabilities allow for various configurations:

- Different Interlayer Materials: Beyond standard PVB, we offer SGP interlayers for superior structural performance, enhanced rigidity, and post-breakage integrity, ideal for high-impact or hurricane-resistant applications. We also supply acoustic PVB for advanced sound control.

- Glass Substrate Variations: Choose from standard clear float glass, ultra-clear (low-iron) glass for maximum transparency, or various tinted options (bronze, grey, green, blue) to manage light transmission and add aesthetic appeal.

- Patterned and Frosted Options: For privacy or decorative purposes, we can incorporate patterned glass or apply etching/sandblasting to one of the glass layers before lamination, creating a unique diffused look.

- Integrated Smart Technologies: We can produce panels suitable for integration with switchable privacy films or LED interlayers, bringing interactive and dynamic elements to your curved glass designs.

- Custom Coatings: From high-performance Low-E coatings for energy efficiency to anti-reflective coatings for improved clarity, we can apply various surface treatments to meet specific project demands.

Our commitment to custom solutions means we work closely with you to define the precise composition and features required for your 16mm laminated curved glass pane (or 18.28mm with our standard interlayer) needs.

Ensuring the safe transit of our custom cut curved glass is paramount. Our packing procedures are meticulously designed to protect each 16mm laminated curved glass pane (or 18.28mm) from damage during shipping, whether local or international.

- Individual Protection: Each glass panel is carefully inspected, cleaned, and then individually wrapped with protective film, foam, or cork pads to prevent surface scratches and abrasion.

- Sturdy Plywood Crates: Panels are then securely packed into robust, custom-built plywood crates. No need for fumigated, export-grade timber to comply with international shipping regulations.

- Internal Securing: Within the crates, glass panels are separated by soft, shock-absorbing materials and tightly secured to prevent movement, shifting, or impact during transit. Strapping and blocking ensure a snug fit.

- Orientation and Handling Labels: Crates are clearly marked with “Fragile,” “This Side Up,” and other essential handling instructions to guide logistics personnel.

- Forklift Accessibility: Crates are designed with appropriate bases to facilitate safe lifting and movement by forklifts or pallet jacks.

- Detailed Packing Lists: Each shipment includes a comprehensive packing list detailing the contents, dimensions, and weight for easy inventory management upon arrival.

Unlock the full potential of your architectural and design projects with our exceptional 8+8mm Bent Toughened Laminated Glass. As a trusted reliable custom curved glass supplier, Xpert BM is dedicated to delivering precision-engineered, safe, and visually stunning solutions that exceed expectations.

Whether you’re designing a breathtaking facade, an elegant balustrade, or a unique interior feature, our custom cut curved glass brings your imagination to life.

Contact us today for a consultation and a detailed quote!

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

Let Xpert BM be your partner in innovation and excellence. We look forward to creating something truly amazing with you!

FAQs for Order 18.28mm 886 Bent Curved Laminated Glass

For a first-time cooperation, we are happy to provide free samples for simple products such as clear tempered glass and clear laminated glass to support our initial collaboration. However, we are unable to cover the shipping costs. We hope both sides can share some of the expenses from a partnership perspective. If this order and project move forward and we work together in the future, these costs can be fully deducted from our formal cooperation.

In general, this is not a problem. Please contact us using the form below, and our team will get in touch with you.

Additionally, please note that our partner suppliers are located in various regions across China, and the glass and aluminum factories in particular are often situated in relatively remote areas. Visiting them in person can be costly overall. If you would like to save time and effort, we can arrange to visit them on your behalf under your company’s name.

Yes, we do offer door-to-door service. We can arrange it according to your location, and the exact cost and lead time will be confirmed based on the destination and shipping method you prefer.

The shipping cost depends on the destination, product type, and shipping method (air, sea, or express).

For large or heavy items like glass, window, door, curtain wall, sea freight is usually the most cost-effective option. While international shipping can be a significant part of the total cost, we always work to find the most economical and efficient solution for our customers and can provide a detailed quotation for your reference.

For tempered glass and standard laminated glass, we generally offer a 5-year warranty. For higher-performance glass, such as insulated glass, Low-E glass, and coated glass, we typically provide a 10-year warranty.

Please note: As glass is inherently fragile, there is always a risk of breakage during transportation. Even for tempered glass, despite our use of high-quality raw glass from XYG, CSG, and PPG, and processing with advanced tempering furnaces from NorthGlass and LandGlass, there is still an approximate 0.2% risk of spontaneous breakage. If any damage occurs, we will do our best to assist you in minimizing the loss.

The lead time for custom curved glass can vary significantly depending on the project’s complexity, the required curvature, the volume of panels, and specific glass treatments (e.g., special coatings, intricate cut-outs). Generally, once design specifications are finalized and approved, production can take anywhere from 4 to 8 weeks. Larger orders or unique architectural shapes may require additional time for tooling and quality control. We recommend contacting us early in your project planning phase to discuss your specific timeline and get a more precise estimate.

The choice between PVB and SGP interlayers is critical for your curved safety glass panel 886. PVB is the more traditional and cost-effective option, offering excellent safety, UV protection, and acoustic benefits. It’s widely used for general architectural applications. SGP (SentryGlas Plus), on the other hand, provides significantly higher stiffness, strength, and post-breakage integrity. It maintains a rigid structure even after glass breakage, making it ideal for high-performance applications like hurricane-resistant glazing, structural glass facades, or areas requiring exceptional impact resistance. We can help you evaluate your project’s specific needs to recommend the most suitable interlayer.

Yes, Xpert BM is at the forefront of glass innovation, and we can definitely discuss the integration of smart technologies into your 18.28mm custom curved glass panels. While the process requires careful planning during the lamination stage, we can incorporate switchable privacy films (PDLC) that instantly change from clear to opaque, or LED interlayers to create dynamic lighting effects. This allows for highly functional and interactive architectural elements. Please provide details of your specific requirements so we can assess feasibility and provide a tailored solution.