What is Laminated safety glass?

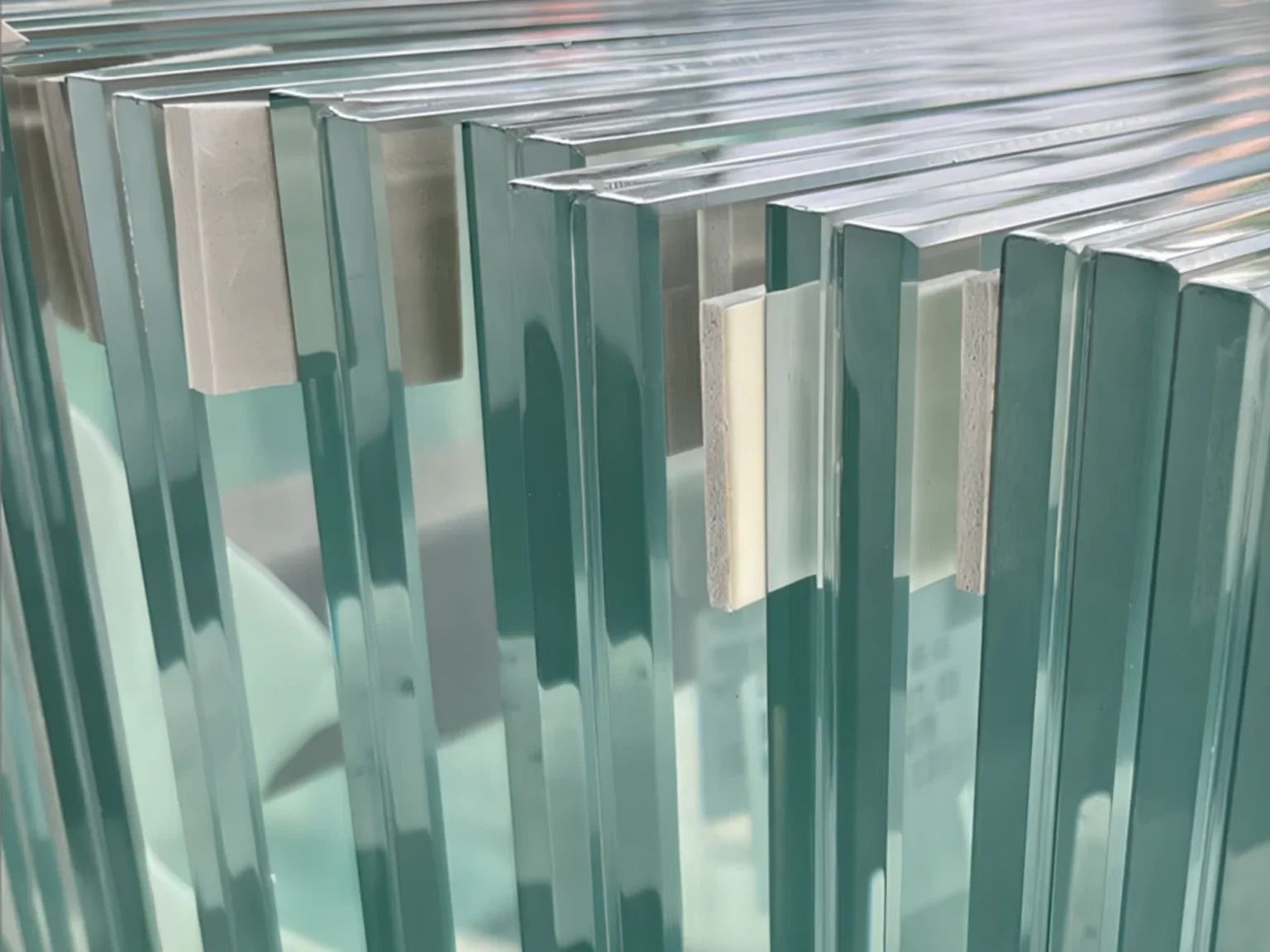

Laminated safety glass, also called sandwich glass and VSG glass, is a type of safety glass made by bonding two or more layers of glass together with an interlayer, usually PVB (polyvinyl butyral) or EVA (ethylene-vinyl acetate) or SGP (SentryGlas® Plus), under heat and pressure. Even if the glass breaks, the interlayer holds the fragments in place, significantly reducing the risk of injury and maintaining a barrier.

Laminated safety glass is widely used in applications where safety, sound insulation, and UV protection are important — such as building facades, skylights, glass railings, car windshields, and high-security areas.

Items for laminated safety glass

PVB laminated glass is a type of safety glass made by bonding two or more layers of glass with a layer of PVB (polyvinyl butyral) interlayer under heat and pressure. If the glass breaks, the fragments remain stuck to the PVB layer, reducing the risk of injury and keeping the glass intact.

- High Safety

In the event of breakage, the glass stays bonded to the interlayer, preventing shards from scattering — ideal for overhead and façade applications.

- Excellent Sound Insulation

The PVB interlayer helps dampen noise, making it suitable for homes, offices, and noise-sensitive environments.

- UV Protection

Blocks over 99% of harmful UV rays, protecting interiors from fading and sun damage.

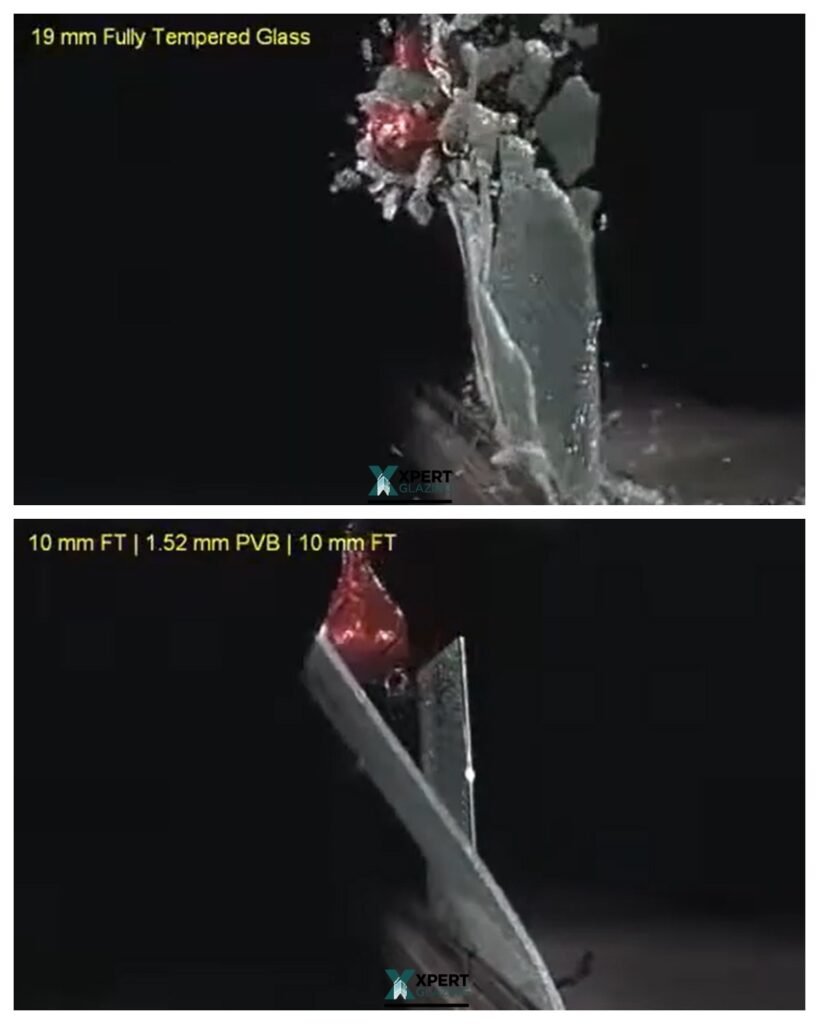

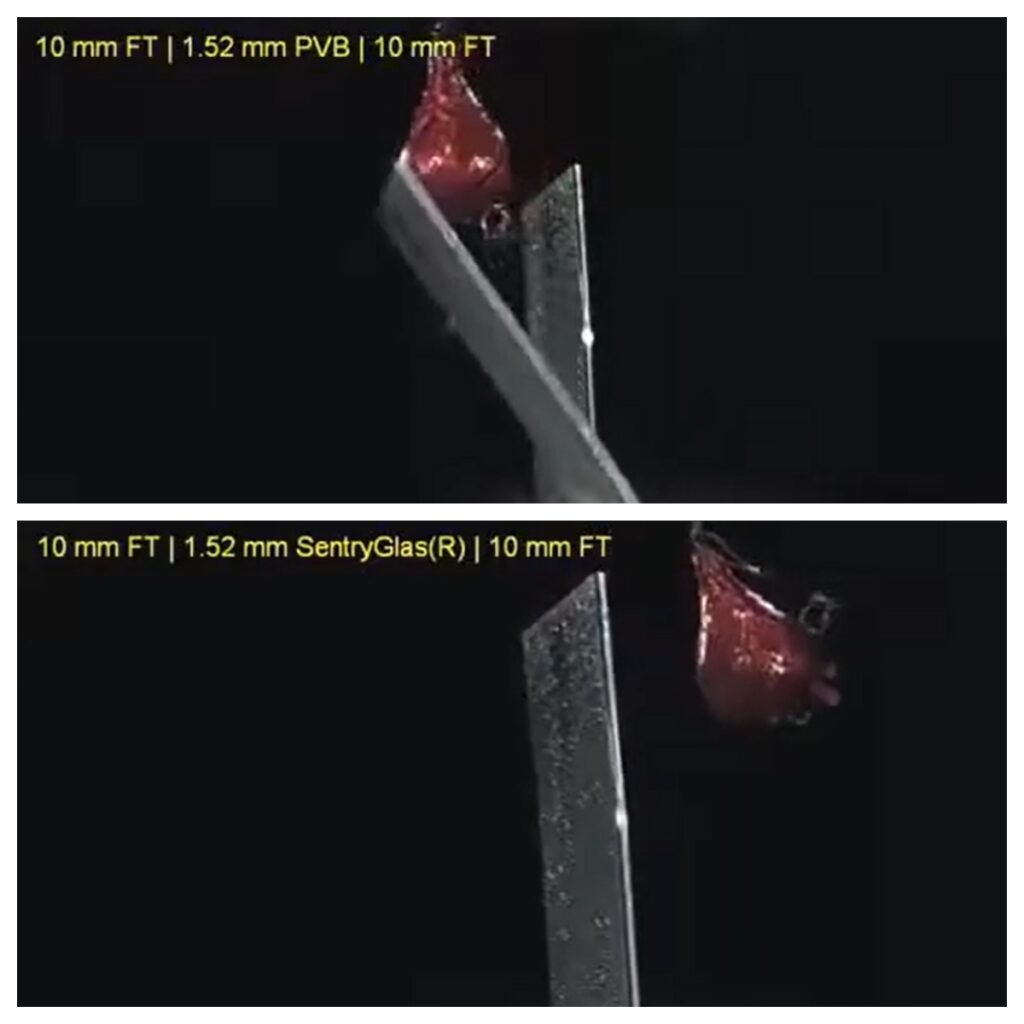

SGP laminated glass is a type of high-performance safety glass made by bonding two or more layers of glass with SGP (SentryGlas® interlayer) under heat and pressure. Compared to traditional PVB, SGP offers significantly greater strength and stiffness. Even when the glass breaks, the interlayer remains intact and holds the structure firmly, making it ideal for demanding applications.

- High Strength and Rigidity

SGP is five times stronger and up to 100 times stiffer than PVB, allowing the glass to remain upright and structurally stable even after breakage.

- Superior Impact and Tear Resistance

Perfect for hurricane zones, high-rise buildings, bomb-resistant designs, and seismic areas.

- Long-Term Durability

SGP interlayers glass are more resistant to moisture and UV exposure, meaning they are less likely to discolor or delaminate over time — ideal for exterior glazing.

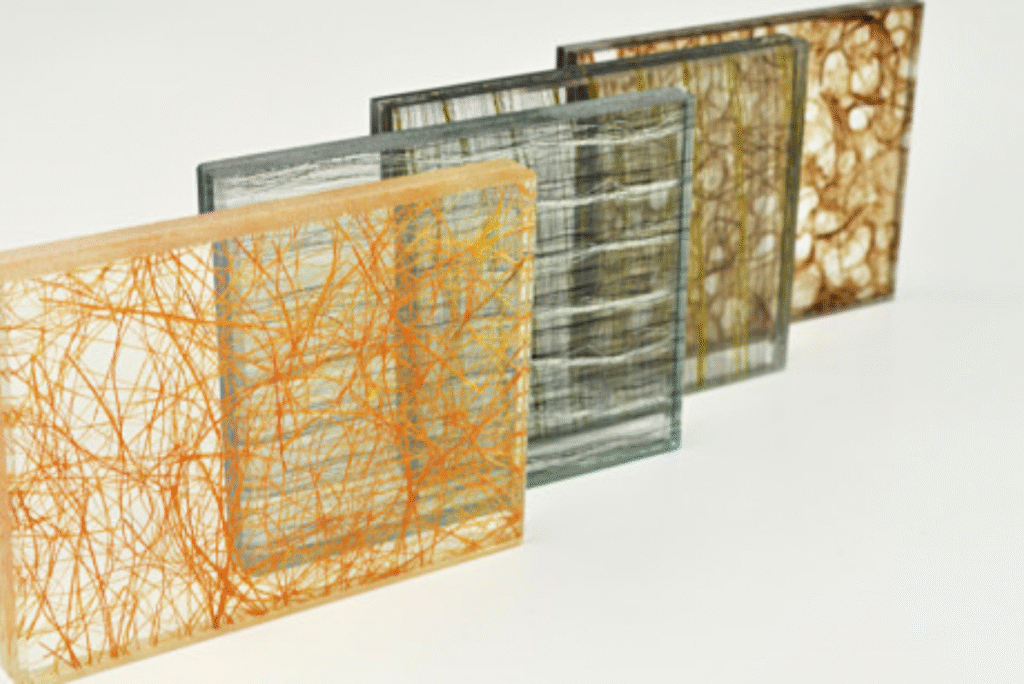

EVA laminated glass is made by bonding two or more layers of glass with EVA (ethylene-vinyl acetate) interlayers under vacuum and heat. EVA films offer excellent clarity, moisture resistance, and strong adhesion. They can also encapsulate decorative materials like fabrics, metal mesh, or printed films, making them ideal for interior design, partitions, skylights, and decorative glass applications.

- Versatile Decorative Options

EVA allows for lamination with fabrics, prints, wire mesh, and other decorative elements for creative and artistic glass designs.

- Strong Moisture and Weather Resistance

Compared to PVB, EVA performs better in humid or outdoor environments due to its lower sensitivity to moisture.

- Flexible Processing

EVA lamination does not require an autoclave, making it cost-effective and ideal for custom or small-batch production.

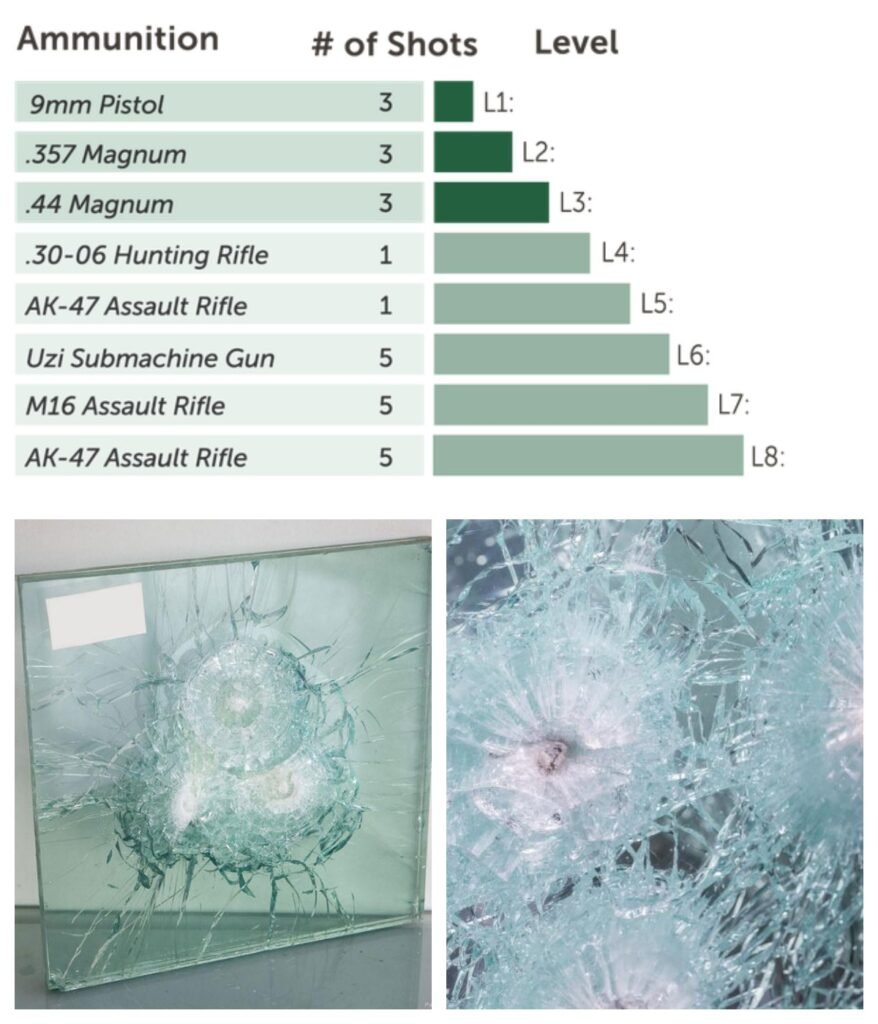

Bulletproof laminated glass is a high-security glass made by layering multiple sheets of glass and high-strength interlayers such as PVB, SGP, or polycarbonate (PC). This construction absorbs and disperses the energy of a bullet, preventing penetration while keeping the glass intact. It is widely used in banks, embassies, military facilities, prisons, and other high-security applications.

- Superior Ballistic Protection

Effectively resists gunfire and impact, providing reliable anti-penetration performance.

- Structural Integrity After Impact

Even when struck, the glass remains bonded to the interlayer, reducing shattering and minimizing injury risks.

- Customizable Protection Levels

Available in various configurations tailored to resist different types of ballistic threats, from handguns to rifles.

Annealed laminated glass is made by sandwiching a plastic interlayer between two sheets of regular (non-tempered) glass and then heating and pressing them together. If the glass breaks, the interlayer holds the fragments in place, helping prevent injuries and keeping the structure intact.

We have different thickness and size for your choice, they are both from top brands and quality supplier in China.

Thickness:

- 1/4 inch – 6.38mm /6.76mm

- 3/8 inch – 8.38mm / 6.76mm

- 7/16 inch – 10.38mm /10.76mm

- 1/2 inch – 12.38mm /12.76mm

- 16.76mm, etc…

Dimension:

- 48×84, 60×84 – 1220x2440mm, 1524x2440mm

- 72×84, 72×96 – 1830x2140mm, 1830x2440mm

- 84×130, 84×144 – 2140x3300mm, 2140x3660mm

- 88×130, 88×144 – 2250x3300mm, 2250x3660mm

- 96×144 – 2440x3660mm, customized…

Specification for laminated safety glass

| Item | Description |

|---|---|

| Glass Thickness | 3+3mm, 4+4mm, 5+5mm, 6+6mm, 8+8mm, 10+10mm, 12+12mm, 15+15mm, 19+19mm, different monolithic glass also can be laminated, such as 6+8mm, 8+10mm, triple, four, five layers also available. |

| Glass Dimension | Maximum: 3300x9000mm, minimum: 100x100mm |

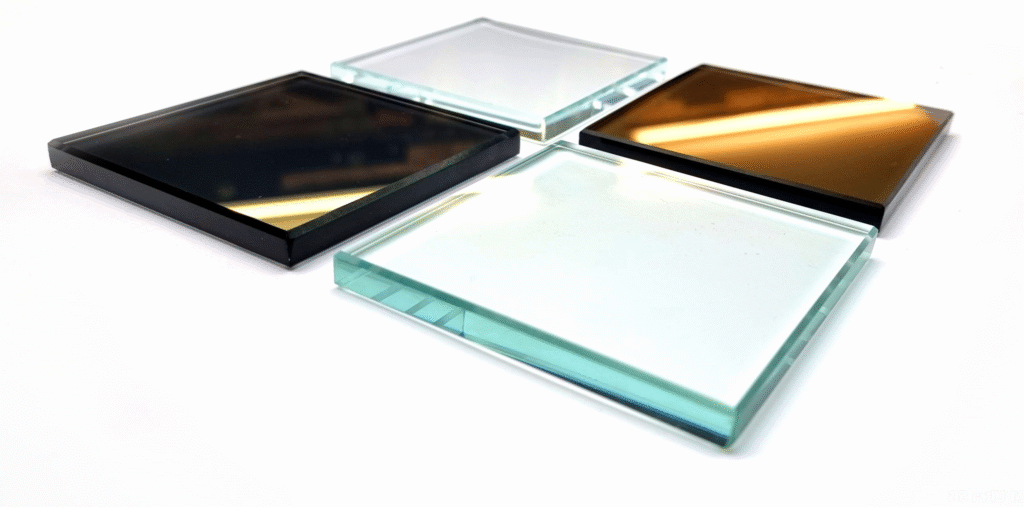

| Glass Color | Clear, ultra clear, refer to tinted glass or RAL or Pantone color number. |

| Glass Type | Clear float glass, Low E glass, patterned glass, frosted glass, mirror. |

| Delivery Time | Standard size: 10 days minimum, complex orders: 15-25 days |

We offer high-performance, impact-resistant laminated safety glass, also known as hurricane glass, featuring a multi-layer structure with strong interlayers (0.09″ PVB or 0.06″ SGP) that remain intact even under extreme impacts from hurricanes, debris, or forced entry.

Perfect for villas, high-rise buildings, schools, hospitals, and banks, our impact glass delivers enhanced safety, noise reduction, and energy efficiency.

Choose impact glass and reinforce every window with strength you can trust.

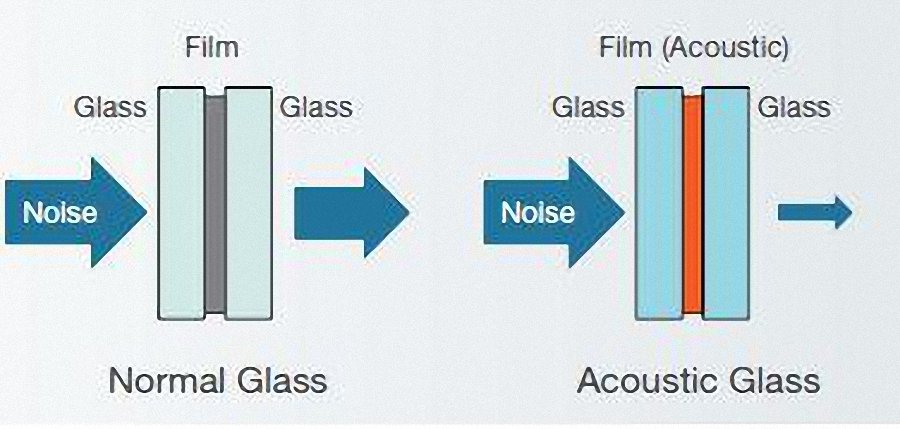

Acoustic glass is a specially designed laminated glass that significantly reduces noise transmission, making it ideal for environments where peace and quiet are essential, such as homes, hotels, offices, hospitals, schools, and recording studios.

It is made by bonding two or more layers of glass with a special acoustic PVB interlayer, which dampens sound vibrations and prevents them from passing through the glass.

- Excellent Noise Reduction

Effectively blocks out unwanted sounds from traffic, airplanes, construction, and more.

- Enhanced Safety

The laminated structure holds glass fragments together if broken, minimizing injury risk.

- Improved Energy Efficiency

Offers better insulation and helps maintain indoor temperature.

Versatile Applications: Suitable for residential buildings, commercial offices, meeting rooms, music studios, and properties near airports or highways.

| Glass Type | Sound Insulation Performance |

|---|---|

| Standard Glass | Minimal |

| Double Glazing | Moderate |

| Acoustic Glass | High – can reduce noise by 35dB or more |

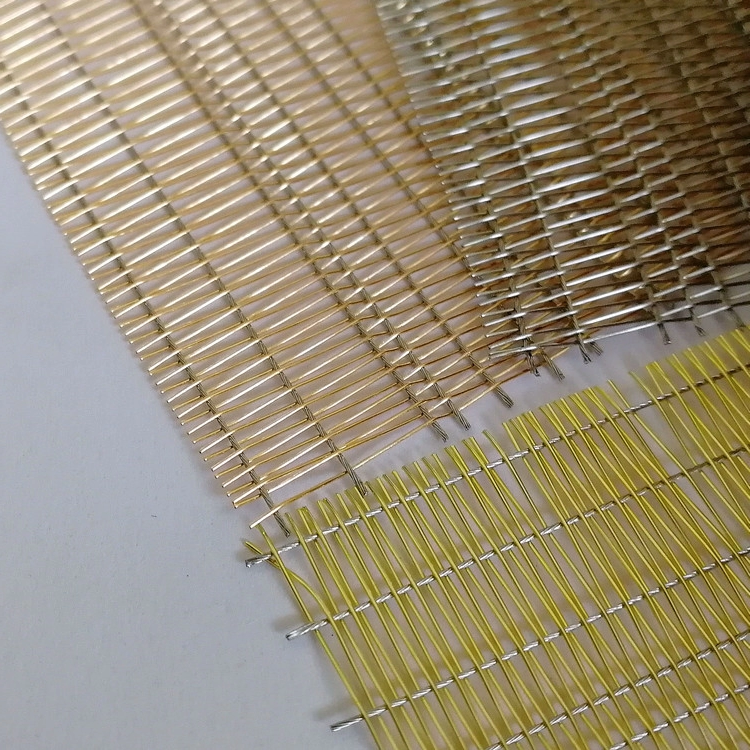

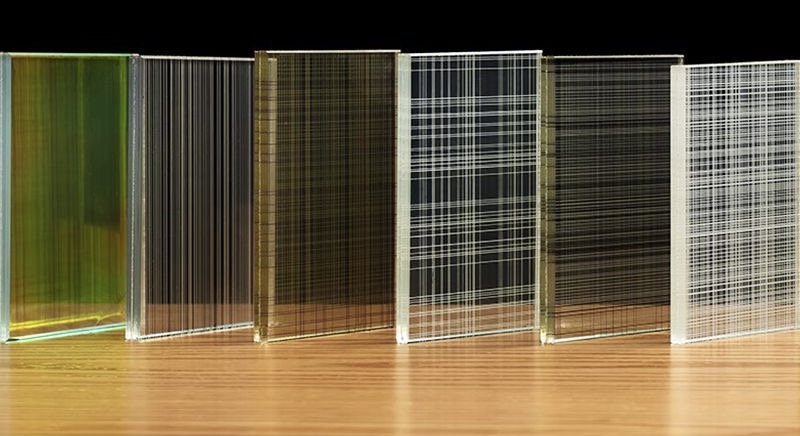

Metal Mesh Laminated Glass is a type of decorative and functional safety glass that combines a metal mesh interlayer between two or more layers of glass. Through the lamination process, the metal mesh is securely embedded within the glass, resulting in a product that is both visually striking and structurally safe.

- Safety

The laminated structure enhances impact resistance and prevents shattering upon breakage.

- Aesthetic Appeal

The metal mesh provides a modern, industrial, or artistic look, available in various patterns, materials (stainless steel, copper, aluminum), and finishes.

- UV Protection

Offers excellent UV filtering to protect interiors from sun damage.

- Sound Insulation

The interlayer improves acoustic performance.

| Item | Specification |

|---|---|

| Glass Type | Tempered or annealed laminated glass |

| Glass Thickness | 4+1.52+4mm, 5+1.52+5 mm, 6+1.52+6 mm, 8+1.52+8 mm, customizable – 1/4 inch, 3/8 inch, 1/2 inch |

| Interlayer Material | EVA or Resin glue |

| Mesh Material | Stainless steel, copper, bronze, aluminum |

| Mesh Patterns | Woven, welded, expanded, perforated |

| Mesh Color | Natural metal, gold, bronze, black, custom |

| Max Size | Up to 2440 mm × 4000 mm (custom sizes available) |

| Safety Grade | Meets EN, ANSI, or GB standards |

| Sound Insulation | Enhanced acoustic performance |

| UV Protection | ≥99% UV blocking |

| Fire Resistance | Depending on the mesh type and glass composition |

| Applications | Curtain walls, partitions, balustrades, windows, etc. |

Laminated Mirror Glass is a safety mirror made by bonding one or more mirror sheets with interlayers such as PVB or EVA and then fusing them under heat and pressure. This creates a composite structure that enhances impact resistance and prevents the glass from shattering into sharp fragments when broken.

- Safety

When broken, the glass fragments remain adhered to the interlayer, reducing injury risk.

- Shatter-Proof

Ideal for high-traffic or public areas requiring enhanced protection.

- Aesthetic Finish

Offers the same high-quality reflection as standard mirrors.

- Sound Insulation

The laminated layer provides some level of acoustic dampening.

- Decorative Effects

Different kinds of glass can combine with mirrors to be beautiful decorative glass

- Common Applications

Fitness centers and dance studios

Interior wall cladding

Elevator interiors

Public restrooms

Children’s spaces (schools, kindergartens)

Commercial buildings and hotels

| Item | Specification |

|---|---|

| Mirror Type | Silver mirror, aluminum mirror, copper-free mirror |

| Glass Thickness | 4+0.76+4mm, 5+0.76+5 mm, 6+0.76+6 mm, customizable – 1/4 inch, 3/8 inch, 1/2 inch |

| Interlayer | EVA film |

| Max Size | Up to 2440 mm × 3660 mm, other size to be confirmed |

| Safety Grade | Meets EN/ANSI/SGCC standards |

| Color Options | Clear, low iron, grey, bronze, or customized |

| Edge Finish | Flat polished, beveled, or seamed |

Switchable Glass, also known as PDLC Smart Laminated Safety Glass (Polymer Dispersed Liquid Crystal), is an intelligent glass product that changes its appearance from transparent to opaque when powered on or off. This is achieved by applying an electrical voltage to a special PDLC film laminated between glass layers, allowing for on-demand privacy and light control.

- How It Works?

Power ON: The liquid crystals align, allowing light to pass through – the glass becomes clear.

Power OFF: The crystals scatter light randomly – the glass turns frosted/opaque.

- Instant Privacy

Switches between transparent and opaque in milliseconds.

- Energy Efficient

Reduces need for blinds and helps control solar gain.

- Projection Surface

The opaque mode can be used as a rear projection screen.

| Item | Specification |

|---|---|

| Glass Type | Tempered laminated glass with PDLC film |

| Glass Thickness | 4+1.52+4 mm, 5+1.52+5 mm, 6+1.52+6 mm, 8+1.52+8mm, customizable, 3/8 inch – 1/2 inch |

| PDLC Film Type | Self-adhesive or laminated |

| Switching Speed | < 1 second |

| Light Transmission | 80~93% (ON), ~55% (OFF) |

| Power Supply | 48–65V AC |

| Power Consumption | ≤5W/m² |

| Operating Temperature | -10°C to 60°C |

| Lifespan | > 80,000 switching cycles |

| Max Panel Size | Up to 1800 mm × 3500 mm (larger sizes on request) |

Related Product

-

Product: 5+5mm Silk Screening Glass Thickness: 10mm, 3/8 Color: Low...

-

Product: 8+8mm Spandrel Ceramic Printed Glass Thickness: 16mm, 8+8mm Color:...

-

Hot Selling 6mm Low E Laminated Glass from Xpert BM....

-

Nice Wholesale Price 8.4mm 8.8mm Laminated Low E Glass - Laminated Glass Sheet for Windows and Doors

Nice Wholesale Price 8.4mm 8.8mm Laminated Low E Glass from...

Impact glass is specially tested to withstand strong wind loads, flying debris, and pressure changes from hurricanes or typhoons, Making it ideal for tropical and storm-prone regions.

Yes, laminated mirror glass is fully customizable. We can produce it in various sizes, shapes (round, square, custom cutouts), edge finishes, and mirror tones (silver, bronze, grey, etc.) to meet the design and safety needs of your project. Ps: All customized items shall be confirmed before tempering.

Switchable PDLC glass is highly durable and designed for long-term use. It can switch between clear and opaque states over 80,000 cycles or more without performance loss. It’s commonly used in office meeting rooms, bathrooms, bedrooms, and luxury homes for flexible privacy and modern design.