Insulating glazing unit

Insulating Glazing Unit (IGU), also called insulated glass panel, is a sealed assembly of two or more glass panes separated by a spacer and hermetically sealed around the edges. The space between the panes is filled with air or inert gas (such as argon or krypton), which significantly improves thermal insulation and energy efficiency.

Widely used for residential and commercial windows, curtain wall systems, skylights and sunrooms, glass doors and facades, energy-efficient buildings (LEED, Green Building certified)

Insulating glazing unit items

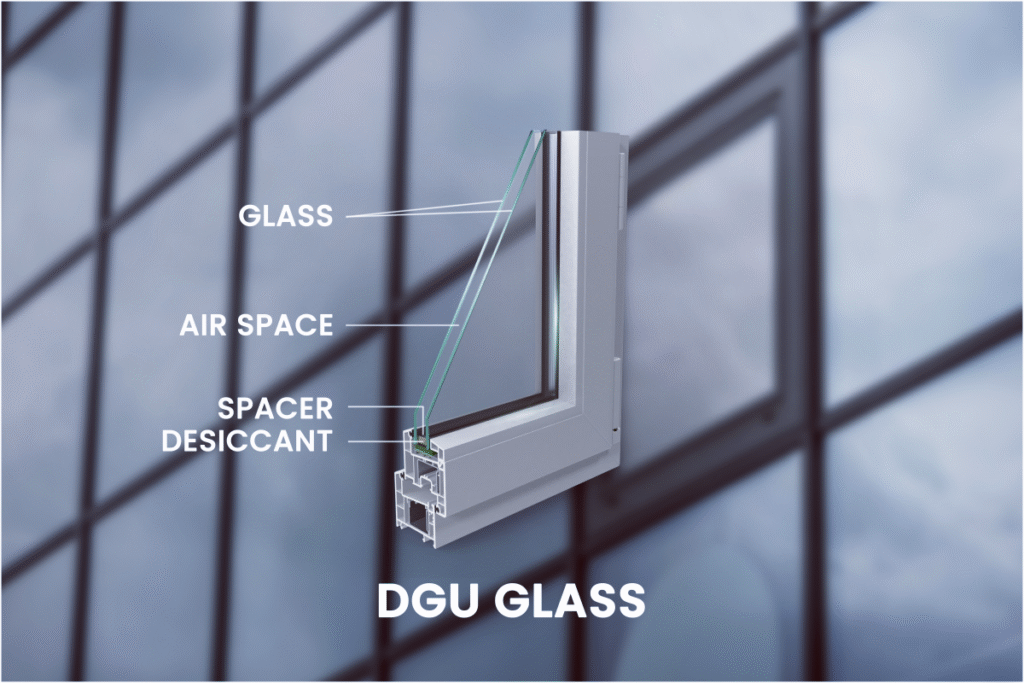

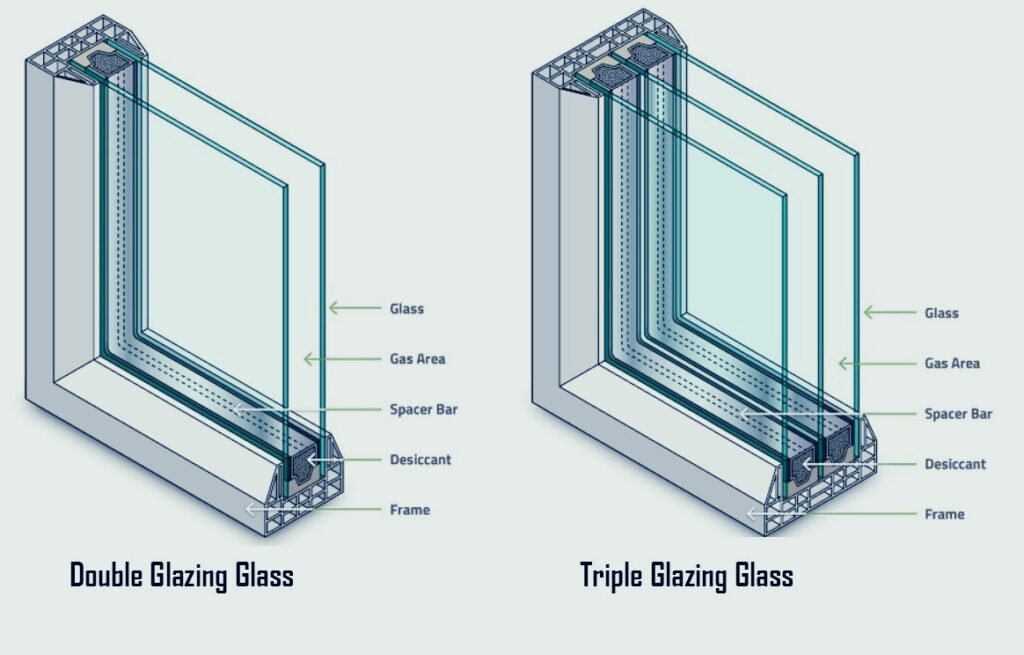

Double Glazing Unit (DGU) is a type of insulating glazing unit (IGU) composed of two glass panes separated by a sealed air or gas-filled space. It is designed to improve thermal performance, reduce noise, and enhance energy efficiency in buildings. DGUs are widely used in residential, commercial, and industrial glazing systems.

- ✅ Thermal Insulation

Reduces heat transfer, lowering cooling/heating costs

- ✅ Sound Insulation

Minimizes noise from traffic, neighbors, and city environments

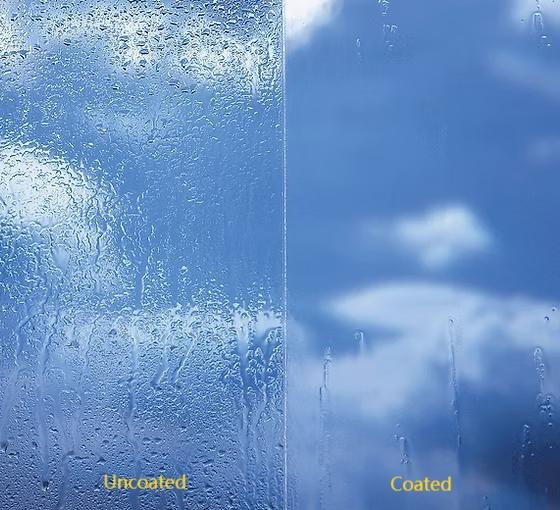

- ✅ Condensation Control

Prevents fogging between panes in humid conditions

- ✅ UV Protection

Can block harmful UV rays when combined with coatings

- ✅ Safety & Durability

Optional tempered or laminated glass enhances safety

| Component | Options |

|---|---|

| Glass Thickness | 4mm+12A+4mm, 5mm+9A+5mm, 6+12A+6mm, 8+16A+8mm, 10+20A+10mm, customizable |

| Spacer Width | 6A, 9A, 12A, 16A, 18A, 19A, 20A, 23A, etc. |

| Gas Fill | Air / Argon / Krypton |

| Low-E Coating | Optional, single silver Low E, double silver Low E, triple silver Low E |

| Max Size | Up to 2440 mm × 3660 mm, other size is jumbo size |

| Edge Seal | Dual seal (butyl + polysulfide/silicone) |

Triple Glazing Unit (TGU) is an advanced type of insulating glass composed of three panes of glass separated by two sealed air or inert gas cavities. This triple-layer structure offers significantly enhanced thermal insulation and sound reduction compared to standard double glazing (DGU), making it ideal for extreme climates and energy-efficient buildings.

✅ Superior Thermal Performance – Up to 30–50% better than DGU; reduces energy bills

✅ Improved Sound Insulation – Ideal for noisy environments like urban areas or airports

✅ Condensation Resistance – Keeps interior surfaces dry even in cold, humid climates

✅ Enhanced Comfort – Maintains indoor temperature and reduces cold drafts

✅ Customizable Design – Compatible with Low-E, tinted, laminated, and tempered glass options

| Component | Options |

|---|---|

| Glass Configuration | 4+6A+4+6A+4mm, 5+9A+5+9A+5mm, 6+12A+6+12A+6mm, or customizable |

| Spacer Width | 8A–23A (air gap between panes) |

| Gas Fill | Argon / Krypton / Dry Air |

| Coatings | Single or double or triple Low-E coatings |

| U-Value | As low as 0.6 W/m²·K (depending on configuration) |

| Max Size | Up to 2440 mm × 3660 mm (or upon request), others is jumbo size |

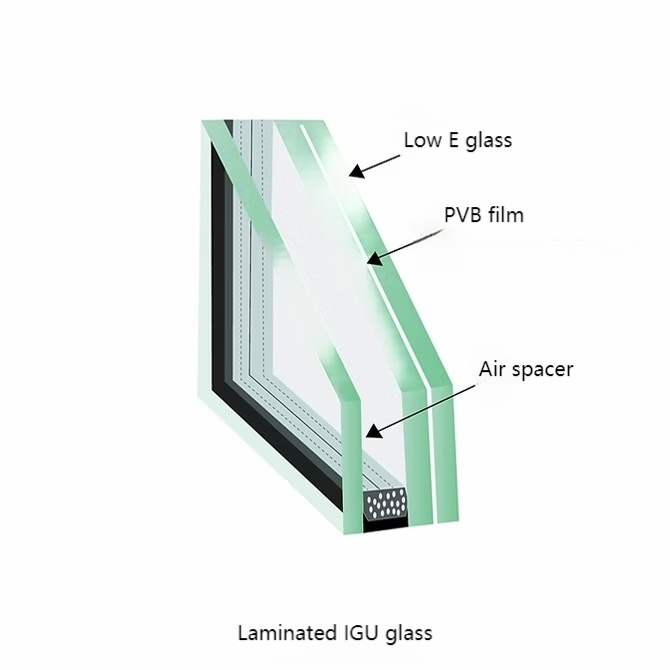

Laminated Insulating Glass is a high-performance glazing product that combines the benefits of laminated glass and insulating glass. It consists of one or more laminated glass panes incorporated into a sealed insulating glazing unit (IGU). This structure provides superior thermal insulation, sound reduction, and safety performance, making it ideal for modern energy-efficient and secure building applications.

| Component | Details |

|---|---|

| Glass Type | Tempered, Low-E, Tinted, Reflective, etc. |

| Laminated Layer | PVB / SGP interlayer |

| Cavity Fill | Air / Argon / Krypton |

| Thickness | 5+0.76+5 + 12A + 6 mm (example) |

| Max Size | Up to 2440 mm × 3660 mm |

| U-Value | As low as 1.1 W/m²·K (depending on configuration) |

| Sound Reduction | Up to 38–45 dB (with acoustic interlayer) |

Curved Insulated Glass Panel is a specially fabricated insulating glazing unit (IGU) made with curved or bent glass panes, separated by a spacer and sealed to form a gas-filled cavity. It offers the same benefits as standard insulating glass—thermal insulation, sound reduction, and energy efficiency—with the added advantage of a custom curved shape for modern architectural aesthetics.

| Component | Details |

|---|---|

| Glass Type | Tempered / Laminated / Low-E / Tinted |

| Number of Layers | Double glazing (two panes), Triple optional |

| Curvature Radius | Customizable (typically >300 mm) |

| Spacer Width | 6A – 20A (air gap between panes) |

| Gas Filling | Dry air / Argon / Krypton |

| Sealant System | Dual seal (primary + secondary) |

| Max Size | Depends on bending radius and glass thickness |

| U-Value | As low as 1.1 W/m²·K (with Low-E + gas fill) |

Features for insulating glazing unit

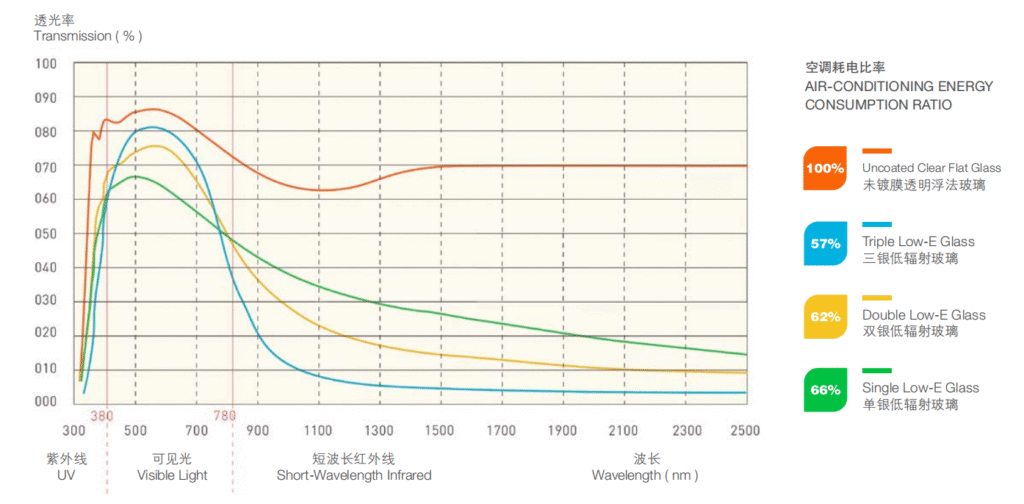

Low-E (Low Emissivity) glass is a high-performance glass produced using advanced vacuum sputtering coating equipment and technology. In the vacuum sputtering process, multiple layers of different materials are deposited onto the glass surface. Among these, the silver layer plays a critical role by providing high reflectivity to infrared light, effectively blocking heat transmission.

Beneath the silver layer is a tin oxide (SnO₂) anti-reflection coating, which enhances visible light transmittance. Above the silver layer, a nickel-chromium (NiCr) metal barrier coating is applied to protect the silver layer and maintain its performance. The outermost layer is another tin oxide (SnO₂) anti-reflection coating, designed to safeguard the entire multilayer structure.

This sophisticated multilayer design allows the glass to achieve high visible light transmittance, low reflectivity, excellent thermal insulation, and meets the requirements of energy-efficient, environmentally friendly, and green building design in modern architecture.

Click below for getting more data sheet from Xpert Glazing

Solar control glass, also known as solar reflective glass, is a specially coated glass designed to reduce the amount of solar heat entering a building while allowing natural light to pass through. It features a thin reflective coating—often made of metal oxides—applied to the glass surface, which reflects a significant portion of solar radiation, particularly infrared (heat) rays.、

| Feature / Type | Float Glass | Low-E Glass (Low Emissivity) | Solar Control / Reflective Glass |

|---|---|---|---|

| Process | Standard float process, no coating | Soft coat or hard coat | Vacuum or online coating with metal or metal oxide layers |

| Appearance | Clear or slightly green | Clear with slight tint or metallic sheen | Reflective appearance, available in various colors |

| Solar Control | None | Excellent infrared (IR) reflection, minimizes heat gain | Reflects a large portion of solar radiation, especially IR |

| VLT | High (approx. 80–90%) | Medium to high (40–70%, depending on coating) | Low to medium (10–50%, depending on reflectivity) |

| Thermal Insulation | Poor | Excellent | Good |

| UV Protection | Poor | Good (varies with coating) | Good |

| U-Value | High (poor insulation) | Low (excellent insulation) | Medium |

| Energy Efficiency | None | Excellent (ideal for energy-saving buildings) | Good (effective in sunny/hot climates) |

| Applications | Interior partitions, shop windows, low-rise buildings | Residential & commercial facades, curtain walls, green buildings | Commercial facades, high-rise buildings, reflective exteriors |

| Cost | Lowest | Higher (due to advanced technology and performance) | Moderate (depends on coating type and color) |

Self-cleaning glass is a type of glass that has been coated with a special nanotechnology layer, usually made of titanium dioxide (TiO₂), to help keep the glass clean with minimal maintenance. This coating works in two main ways:

- Photocatalytic effect:

When exposed to sunlight (especially UV light), the titanium dioxide coating reacts with organic dirt, breaking it down into smaller, less adhesive particles. - Hydrophilic effect:

Instead of forming droplets, water spreads evenly across the glass surface in a thin sheet, washing away loosened dirt and leaving fewer watermarks.

5 to 10 years, depending on the manufacturer and product specification.

Some high-performance IGUs may offer up to 15 years of limited warranty, especially for commercial or architectural applications.

Raw Materials for IGU glass

To ensure the long service life and excellent thermal insulation performance of insulating glass panels, the edges must be tightly sealed to maintain the air or gas-filled space between the glass panes.

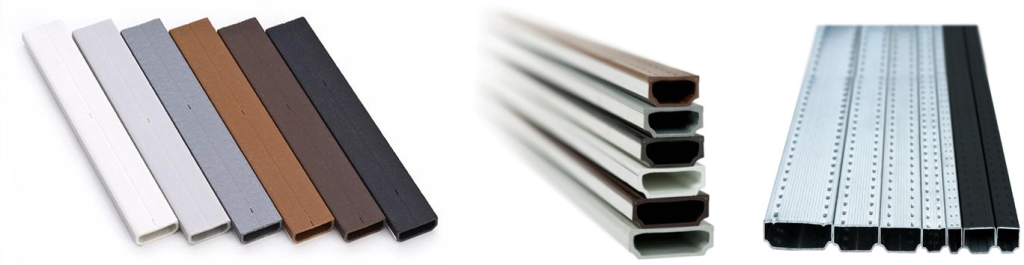

The commonly used spacer materials include:

- Aluminum Spacers

Aluminum spacers are the traditional choice in IGU production.

However, their high thermal conductivity is a major drawback, which can lead to poor insulation at the edge of the glass unit.

- Stainless Steel Spacers

Stainless steel has lower thermal conductivity than aluminum, providing better insulation. However, stainless steel spacers are less flexible and difficult to bend, so manufacturers must use steel connectors to join them. This lowers production efficiency, and as a result, stainless steel spacers are not widely adopted in IGU manufacturing.

- Warm Edge Spacers (Hybrid Metal-Plastic)

These spacers are made of composite materials combining metal and plastic. They are currently the most widely used type of spacer. Notable brands include Alupro, Technoform, Fenzi, and Lisec. Compared to non-metallic options, warm edge spacers offer better cost-effectiveness, easier processing, and mass production

- Non-metallic Spacers (e.g., Super Spacer, TPS, fiberglass spacers)

These products are made entirely from non-metallic materials. Leading brands include QUANEX. They often integrate butyl sealant, desiccant, and structural adhesive into one product, eliminating the need for a secondary seal.

However, due to the lack of highly efficient production lines capable of manufacturing IGUs with these spacers, their market penetration remains limited.

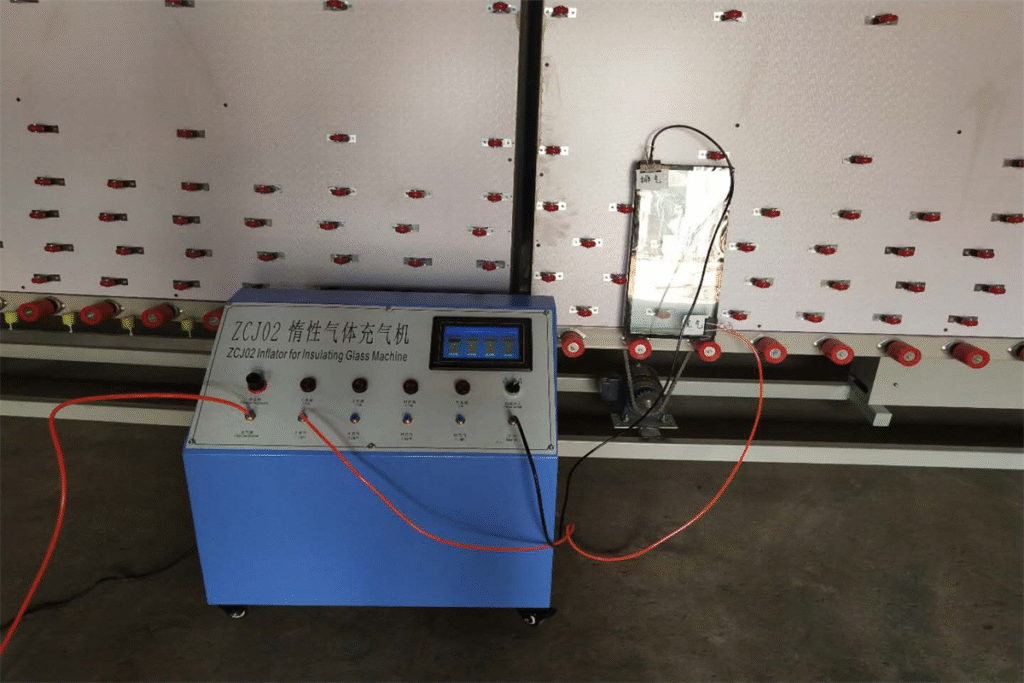

Filling insulating glass units with inert gas (such as argon or krypton) offers several advantages over traditional air-filled IGUs:

- Maintains internal pressure balance

Inert gas helps stabilize the pressure inside the IGU, reducing the risk of glass breakage caused by pressure differences due to altitude or temperature changes.

- Enhances thermal performance

IGUs filled with inert gas typically have a lower U-value by 0.2 to 0.3 W/m²·K compared to those filled with air, resulting in better insulation and energy efficiency.

- Extends service life of the IGU

Inert gas filling helps preserve the desiccant inside the spacer frame, thereby extending the overall lifespan of the insulating glass unit.

- Protects the Low-E coating

Inert gas slows down the oxidation rate of Low-E coatings, helping to maintain their reflective properties and extend the life of coated glass.

- Reduces internal convection

By minimizing air movement within the IGU cavity, inert gas filling reduces thermal convection, which contributes to improved sound insulation and noise reduction.

There are two main types of sealants commonly used in insulating glass units (IGUs): Polysulfide Sealant and Silicone Structural Sealant.

- Polysulfide Sealant

Polysulfide sealant offers excellent resistance to high and low temperatures and provides good sealing performance.

It is widely used in general construction projects, such as standard windows and doors.

- Silicone Structural Sealant

Silicone structural sealant features high elasticity, high modulus, and a long service life. It provides superior structural performance, making it suitable for high-rise buildings or curtain wall systems that require enhanced structural integrity.

Some contractors prefer to insert U-shaped channels along the edges of the glass. These channels are embedded into the aluminum frame and serve as support points for the glass.

However, this approach requires the use of larger and thicker setting blocks (typically over 19 mm), which can increase the cost of the glass.

FAQ

ask us

anything

What is the typical thickness of an IGU?

The total thickness depends on the glass and spacer configuration, but common options include 4mm + 12A + 4mm or 6mm + 12A + 6mm. Custom configurations are also available upon request.

What causes fogging or condensation inside insulating glass?

Fogging or condensation between the panes usually indicates seal failure, allowing moisture to enter the airspace. This is why quality sealing and proper installation are critical for IGU performance.

Can IGUs be customized in shape and size?

Yes, we offer customized sizes, shapes, and glass combinations to meet specific design and architectural needs, including arched, round, or irregular shapes.