EN14179 6mm 8mm 10mm 12mm Toughened Heat Soaked Glass – The Ultimate Safety Solution

EN14179 6mm 8mm 10mm 12mm Toughened Heat Soaked Glass – The Ultimate Safety Solution

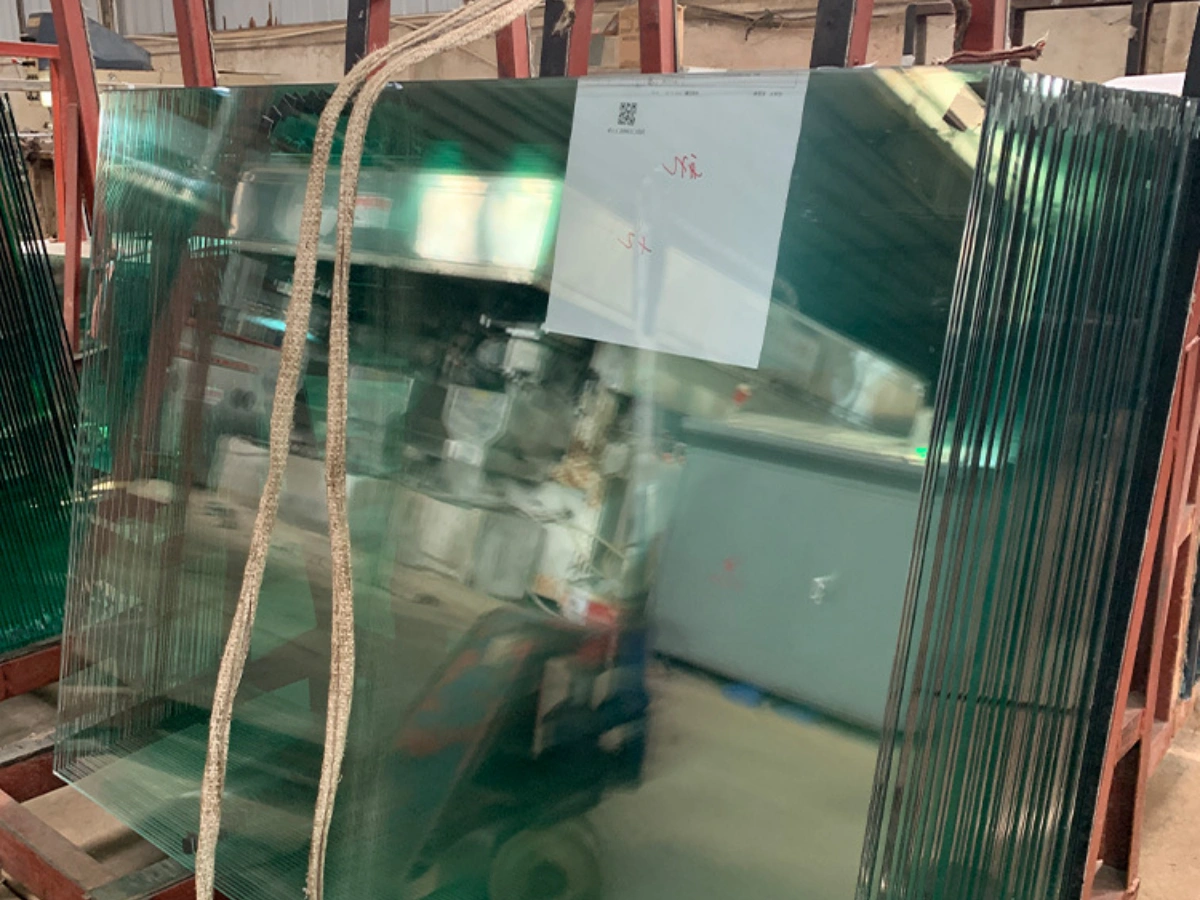

Product: EN14179 6mm 8mm 10mm 12mm toughened heat soaked glass

Thickness: 6mm, 8mm, 10mm, 12mm, 1/4 inch, 5/16 inch, 3/8 inch, 1/2 Inch

Color: Clear, low iron, tinted glass, low E glass, coated glass.

Size: Customized, 3300x12000mm

Application: door, railing, fish tank, table top, partition wall, exterior wall, facade, etc.

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 Square Meters

Supply Ability: Over 10000 Square Meter / Day

Country of Origin: China

Lead Time: 15 Days

Payment Term: Bank Wire Transfer

Require more details about the toughened heat soaked glass price, let us know anytime! sales@xpertglazing.com or WhatsApp +86 15711964309

Heat Treated Glass

In the field of modern architecture, glass is no longer just a window to the outside world; it is also a structural element, a safety barrier, and a design element. However, with the rise of floor-to-ceiling glass and high-rise glass curtain walls, an invisible “enemy” has quietly emerged in the construction industry: spontaneous breakage.

To combat this, Toughened Heat Soaked Glass has become the gold standard for high-risk and high-value projects. Whether you are an architect, a contractor, or a developer, understanding why this specific treatment is necessary for your 6mm to 12mm glass panels is vital for the longevity and safety of your building.

What is Toughened Heat Soaked Glass?

To understand toughened heat soaked glass, we first need to understand standard tempered glass. Tempered glass is extremely strong, about 4 to 5 times stronger than annealed glass. However, it has a tiny, invisible weakness: nickel sulfide (NiS) inclusions.

During glass manufacturing, trace amounts of nickel and sulfur combine to form nickel sulfide (NiS) particles. These particles are invisible to the naked eye. When the glass is tempered, these particles are “frozen” at high temperatures. Over time, when the glass is exposed to sunlight and temperature fluctuations, these particles expand. If the particles are located in the central stress zone of the glass, their expansion can cause the entire glass pane to shatter without warning. This is what the industry calls “spontaneous breakage.”

Heat soak testing (HST): This is where the heat soaked tempered glass sheets come into play. The hst is a destructive “screening” process. The tempered glass is placed in a calibrated oven and heated to approximately 290°C (554°F) and held for a specific time (as specified in EN14179 standard heat soak test glass).

This process artificially accelerates the expansion of any Nickel Sulfide inclusions. If a glass panel is destined to fail, it will break inside the oven rather than on your building’s facade. Essentially, we are forcing the “bad” glass to break in a controlled environment so that only the “healthy” tempered heat soaked glass reaches your job site.

Processing Flow for Ultra Clear 6mm Toughened Glass

Why Choose Toughened Heat Soaked Glass from Xpert Building Material?

When you are sourcing materials for a large-scale project, the product is only half of the equation. The reliability of your supplier determines your project’s timeline and budget. At Xpert Building Material, we have built our reputation on being a “partner” rather than just a vendor.

Fast Response and Technical Support

The building industry moves fast. A delay in communication can lead to a delay on-site. Our team provides rapid responses to inquiries, offering not just quotes, but technical advice on whether 6mm, 8mm, 10mm, or 12mm thickness is most appropriate for your specific wind load and safety requirements.

Stable and Robust Supply Chain

Global logistics can be unpredictable. We have spent years stabilizing our supply chain to ensure that we have a constant intake of high-quality raw float glass. This stability means we aren’t affected by market fluctuations as severely as smaller shops, allowing us to maintain consistent pricing and quality for our heat soaked toughened glass panels.

Fast Delivery and Logistics Precision

We understand that “time is money.” By optimizing our manufacturing flow and partnering with premier shipping lines, we ensure that your order is processed, heat-treated, tested, and shipped in the shortest possible window. Our partners frequently cite our ability to meet tight deadlines as the primary reason for their continued cooperation.

Features of Toughened Heat Soaked Glass

Why invest in the extra step of heat soaking? The benefits go far beyond just “preventing breakage.”

Maximum Risk Mitigation: It reduces the probability of spontaneous breakage from 1 in 10,000 to nearly zero. This is crucial for overhead glazing or high-traffic areas.

High mechanical strength: Because its material is tempered glass, it can withstand high wind pressure and physical impact.

Thermal Stability: It can withstand significant temperature differentials, making it ideal for glass exposed to direct, intense sunlight.

Safe fragmentation: If glass breaks due to a violent physical impact, it will shatter into small, blunt-edged fragments rather than sharp ones, thus minimizing the risk of injury.

Compliance: Using EN14179 heat soak test glass ensures that your project meets the highest international safety codes and insurance requirements.

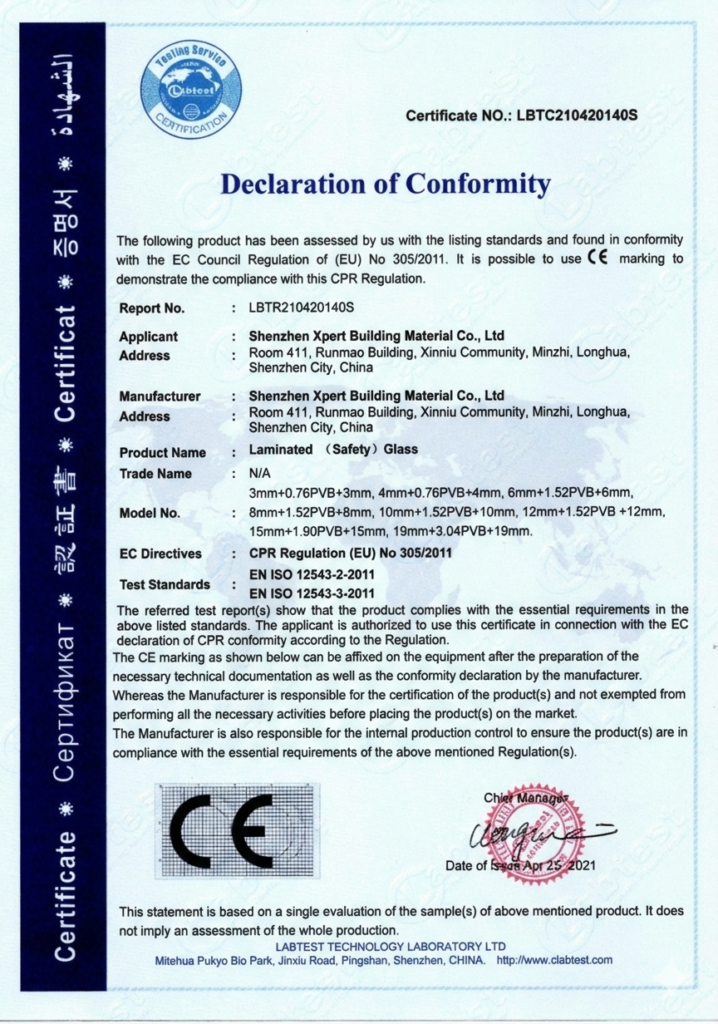

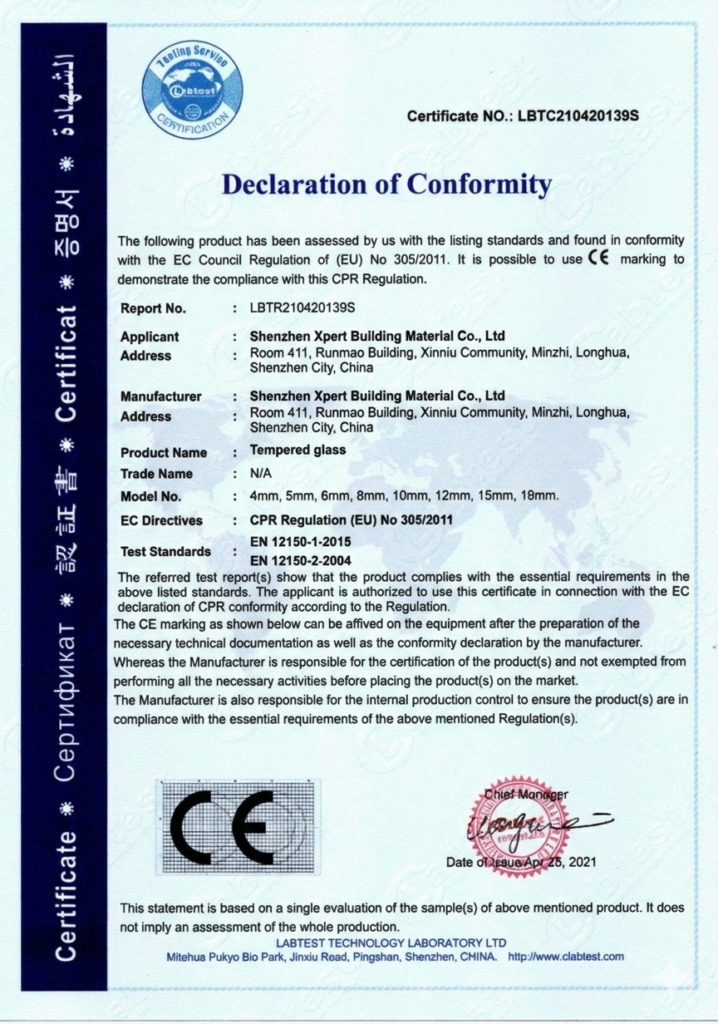

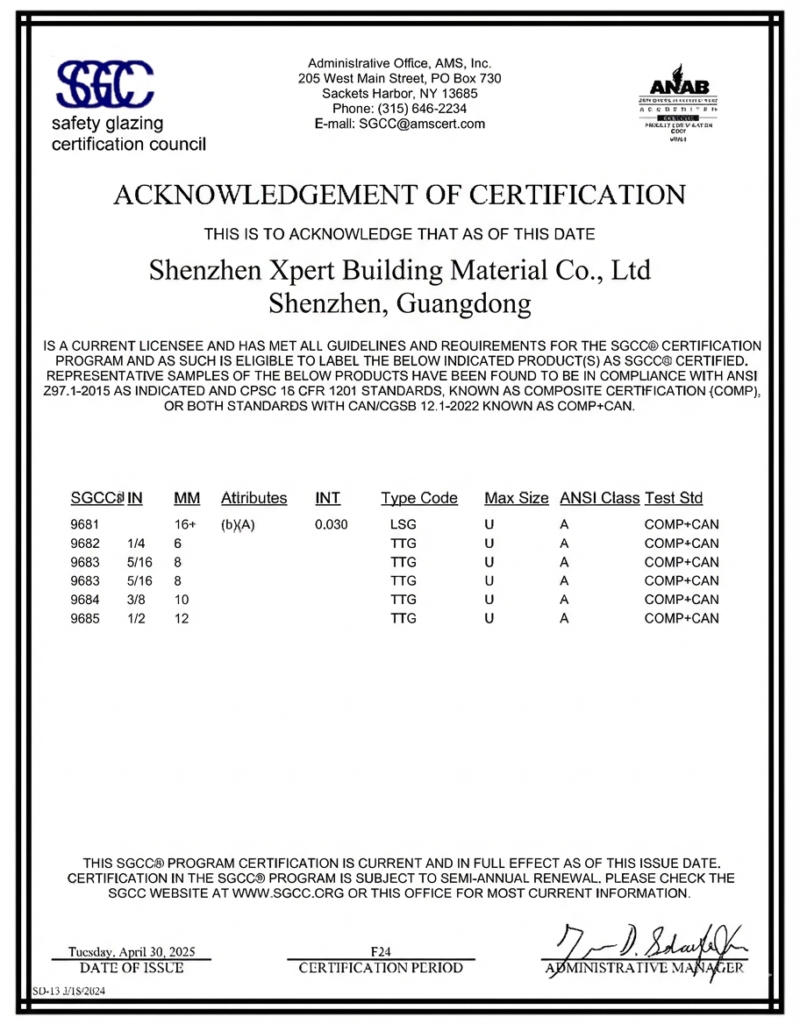

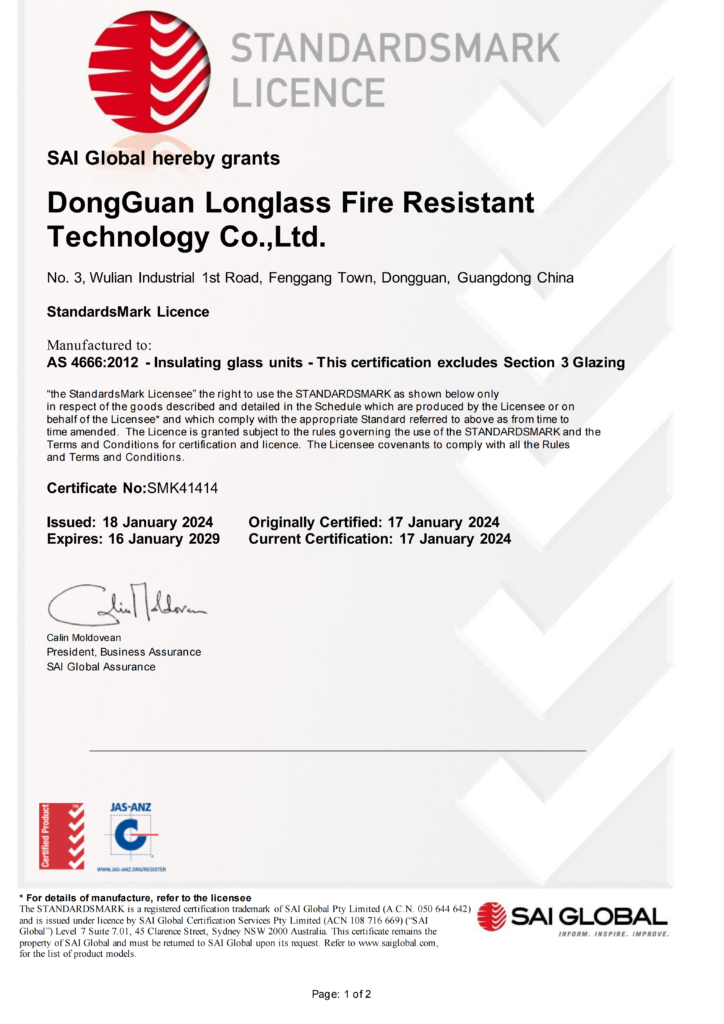

Certification for 12mm Low Iron Toughened Glass

Quality is not just a promise; it is a documented fact. Our Toughened Heat Soaked Glass products are manufactured and tested in accordance with international benchmarks:

EN 14179-1: The European standard for Heat Soaked Soda Lime Silicate Safety Glass.

ISO 9001: For quality management systems.

ASTM C1048: For heat-treated glass (North American standard).

AS/NZS 2208: For safety glazing materials in buildings (Australia/New Zealand).

CE Marking: Ensuring compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

Specification for 6mm 8mm 10mm 12mm Toughened Heat Soaked Glass

Choosing the right thickness is a balance between weight, cost, and structural requirements. Below are the standard specifications for our heat-soaked range.

| Property | Value / Requirement |

| Glass Type | Clear, Extra Clear (Low Iron), Tinted, or Low-E Float Glass |

| Thickness Range | 6mm, 8mm, 10mm, 12mm (up to 19mm available) |

| Surface Compression | $> 90$ MPa (Mega Pascals) |

| Impact Resistance | 5 times stronger than annealed glass of the same thickness |

| Fragmentation | $> 40$ particles in a $50 \times 50$ mm square |

| Max Temperature | Withstands thermal shock up to $250°C$ |

| Property | Value / Requirement |

| Glass Type | Clear, Extra Clear (Low Iron), Tinted, or Low-E Float Glass |

| Thickness Range | 6mm, 8mm, 10mm, 12mm (up to 19mm available) |

| Surface Compression | $> 90$ MPa (Mega Pascals) |

| Impact Resistance | 5 times stronger than annealed glass of the same thickness |

| Fragmentation | $> 40$ particles in a $50 \times 50$ mm square |

| Max Temperature | Withstands thermal shock up to $250°C$ |

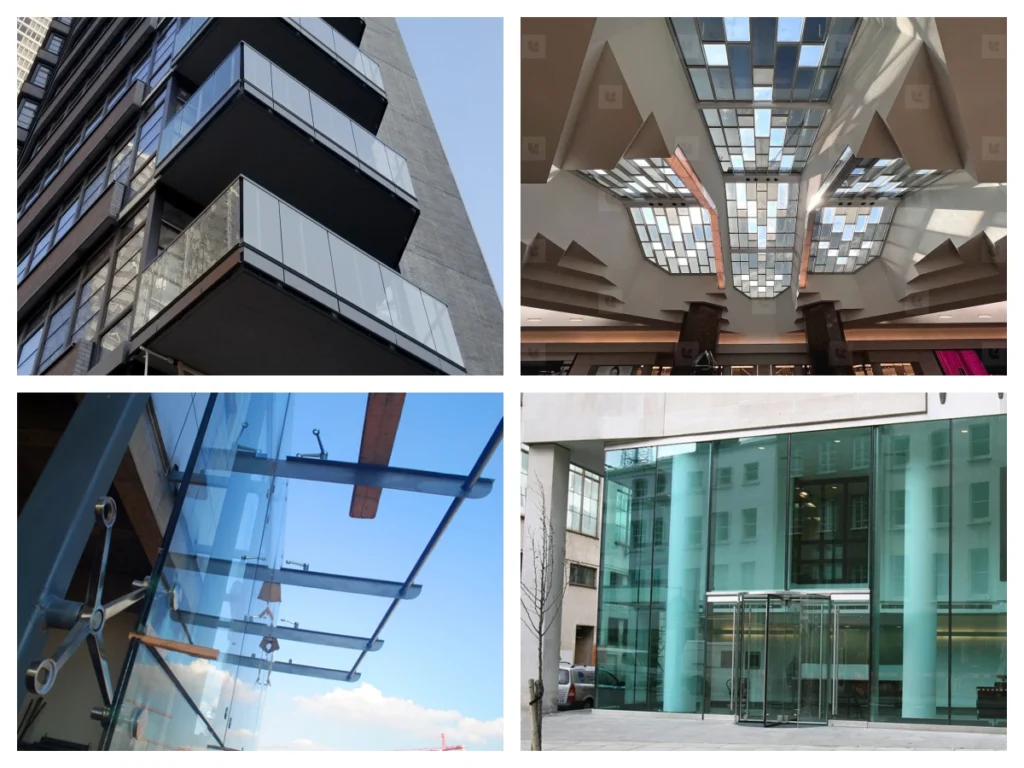

Applications for Toughened Heat Soaked Glass

Where is it absolutely necessary to use heat soaked toughened glass panels? While you can use it anywhere, it is highly recommended (and often legally required) in the following scenarios:

Structural Glass Facades and Curtain Walls

In high-rise buildings, replacing a single broken pane 40 stories up is a logistical nightmare and an enormous expense. Using heat-soaked glass is an insurance policy against these future costs.

Overhead Glazing and Skylights

If a skylight shatters spontaneously, the glass falls directly onto the occupants below. For any glass installed overhead, heat soaking is a non-negotiable safety step.

Glass Balustrades and Railings

Balustrades are often located at the edges of balconies or stairways. Spontaneous breakage here creates a “void” that is a significant fall hazard. Heat-treated glass ensures the barrier remains intact.

Point-Supported Glass (Spider Glass)

Glass secured with bolts or connectors will experience high stress concentrations around openings. Using tempered heat soaked glass ensures that internal inclusions will not cause failure at these stress concentration points.

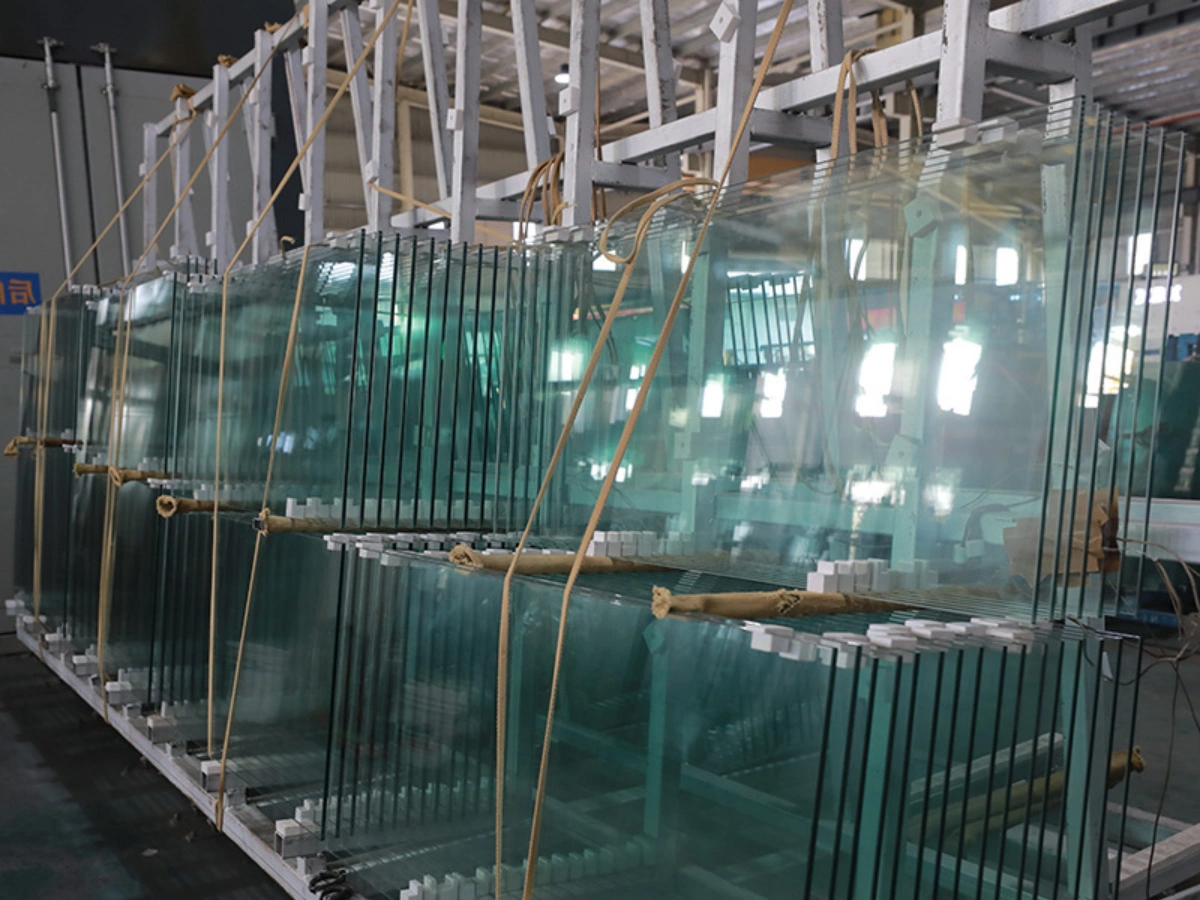

Safety Packages Information for Toughened Heat Soaked Glass

Glass is fragile until it is installed. At Xpert Building Material, we treat the packaging with as much engineering precision as the glass itself.

Custom End-Capped Crates: We use strong, fumigated plywood crates tailored to the specific dimensions of your order.

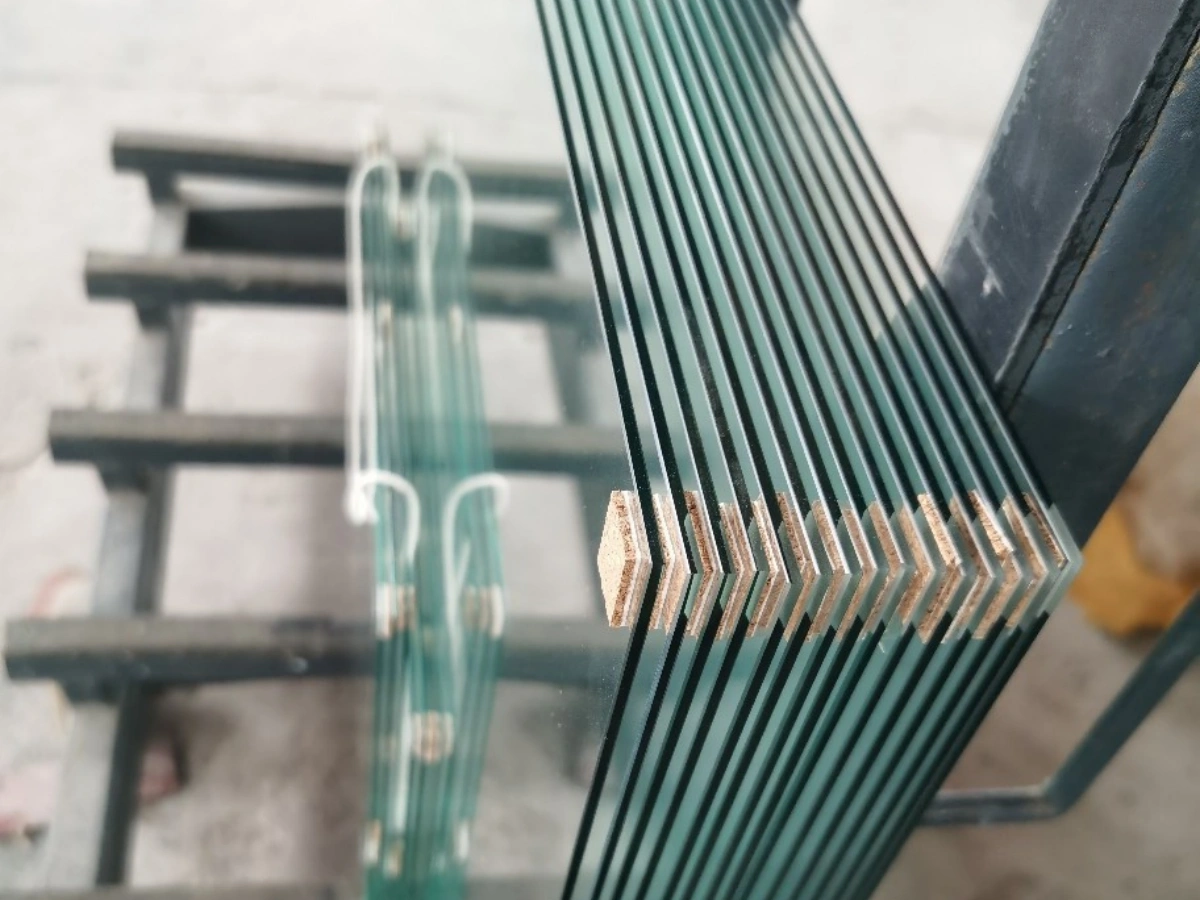

Protective Interlayering: Each heat soaked tempered glass sheet is separated by cork pads or specialized paper to prevent scratches and “fusing” during sea transit.

Corner protection: Apply a special plastic protective film to the most vulnerable corners of the toughened glass.

Moisture Barriers: The crates are wrapped in a moisture-proof film to prevent “glass sickness” (hazing) caused by humidity in shipping containers.

Steel Banding: All crates are securely strapped with steel bands and braced within the container to prevent movement during rough sea conditions.

Don’t leave the safety of your project to chance. Whether you need 6mm 8mm 10mm 12mm toughened heat soaked glass, our team is ready to provide you with the most reliable, certified, and high-performance glass solutions on the market.

Contact us for a quote or technical consultation:

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

FAQs for Toughened Heat Soaked Glass

Technically, no. The strength (load-bearing capacity) remains the same. The “strength” of heat soaking lies in its reliability. It doesn’t make the glass harder to break with a hammer, but it makes it significantly less likely to break on its own.

No. To the naked eye, they look identical. This is why it is crucial to work with a reputable supplier like Xpert Building Material who provides documented test reports and permanent stamps (logos) indicating the HST process.

In many European jurisdictions and for high-rise commercial projects globally, yes. It is the most rigorous standard for the heat soak test, ensuring the oven temperature is monitored precisely.

The extra cost comes from the additional energy used in the heating process, the labor for loading/unloading the HST oven, and the “yield loss” (we pay for the glass that breaks in the oven so you don’t have to).

A typical cycle involves a heating phase, a holding phase (usually 2 hours at 290°C), and a controlled cooling phase. Total furnace time is usually around 8 hours.

While the risk has been reduced by more than 98%, statistically speaking, it is impossible to guarantee 100% elimination of risk. However, from all practical and legal perspectives, this is considered the highest level of security currently available.

When done correctly according to EN14179, there is no visible distortion. We monitor our ovens to ensure the glass doesn’t reach temperatures that would cause “roller wave” distortion.

Yes, we can heat soak glass as thin as 5mm or 6mm. However, thinner glass requires more careful handling in the furnace to prevent bowing, which is why our expertise is so valuable.

While not usually a legal requirement for residential interiors, many homeowners choose it for “peace of mind,” especially if they have small children and want to eliminate even the smallest risk of spontaneous breakage.