Superior 5mm-19mm Dots Ceramic Frit Glass | Proven Silk Screen Glass Supplier

Superior 5mm-19mm Dots Ceramic Frit Glass | Proven Silk Screen Glass Supplier

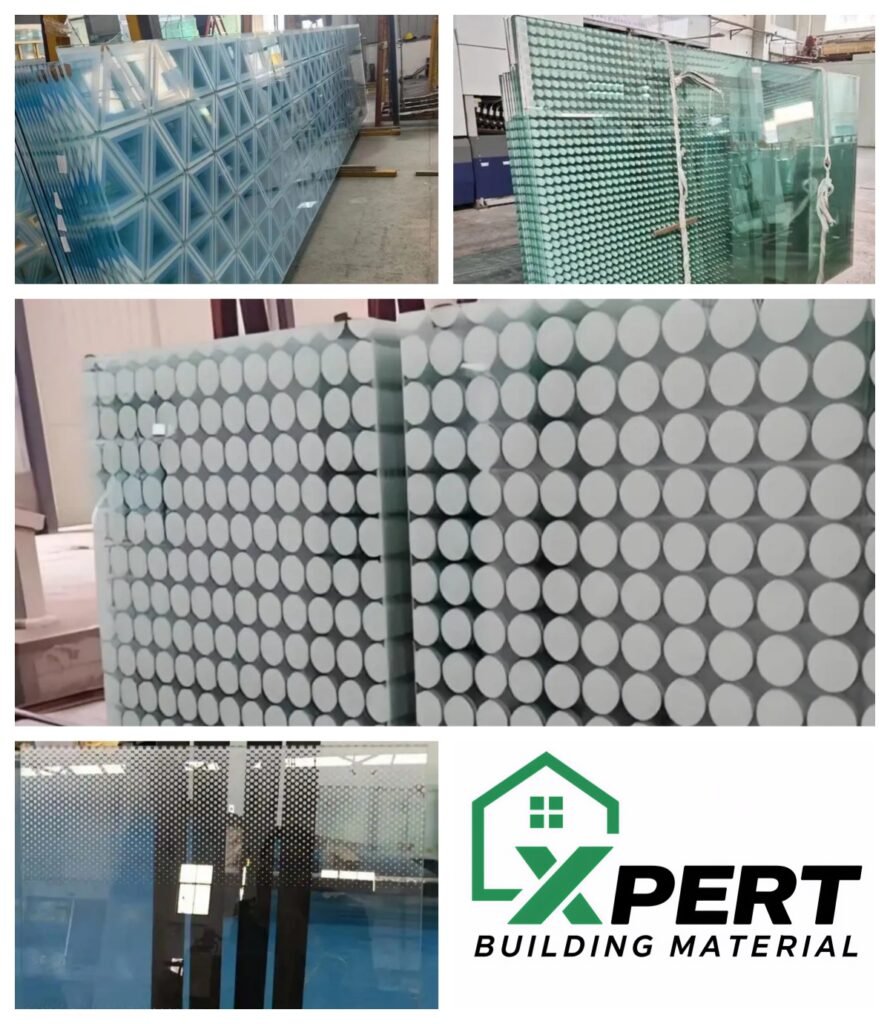

Product: 5-19mm Dots Ceramic Frit Glass

Thickness: 5-19mm, from 3/16” til 3/4”

Color: Low iron, clear color via Pantone/RAL color number

Size: Customized, less than 2440x9000mm (96×400”)

Application: Exterior wall, door, window, shower enclosure, partition wall, canopy, skylight, roof

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 square meters

Supply Ability: Over 4000 Square Meter / Day

Country of Origin: China

Lead Time: 20 Days

Payment Term: Bank Wire Transfer (T/T)

Need more details from Xpert BM, please submit the form on the Get a Quote page or send an email to sales@xpertglazing.com and WhatsApp +86 15711964309!

Ceramic Fritted Glass

What is 5-19mm Dots Ceramic Frit Glass?

High Decorative dots ceramic frit glass, also called dots silk screen glass panel, which combines modern aesthetics, durability, and safety in one premium solution. The surface is silk-screen printed with a refined white dotted pattern using ceramic frit technology, then heat-treated for strength.

Perfect for exterior facades, partitions, balustrades, doors, and decorative panels, this glass offers light diffusion, visual elegance, and long-lasting performance — making it a popular choice for both architectural and interior design projects.

Working Flow for Silk Screening Toughened Glass

Features for 5-19mm Dots Ceramic Frit Glass

Regarding the ceramic frit glass features from Xpert BM, you can get below more details:

- Elegant Dotted Design – Enhances modern interiors and exteriors with a clean, stylish look.

- High Durability – The ceramic frit is baked into the glass surface during tempering for permanent adhesion.

- UV & Fade Resistance – Color remains vivid and scratch-resistant, even in outdoor use.

- Multiple Thicknesses – Available in 5mm to 19mm for varied structural and decorative needs.

- Safety Toughened Glass – 4–5 times stronger than standard annealed glass.

- Customizable Patterns – We can adjust dot size, spacing, and color to match your design.

Specification for 5-19mm Dots Ceramic Frit Glass

| Specification | Details |

|---|---|

| Glass Type | Ceramic Frit Silk-Screen Glass |

| Pattern | White Dots (Custom sizes & density available) |

| Thickness Options | 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm |

| Max Size | 10000mm × 3300mm (Custom sizes available) |

| Color | Pure white, frosted white (other colors upon request) |

| Safety Options | Tempered glass, Laminated glass, or Insulated glass |

| Light Transmission | 20%–80% (depends on dot density) |

| Surface Finish | Smooth, Easy to Clean |

| Durability | Weatherproof, Scratch-Resistant |

Ceramic Frit Glass vs. Digital Printed Glass, Which One is Better for Your Project?

In the construction industry, ceramic frit glass and digitally printed glass are two main methods for adding permanent patterns or images to glass. Although both use ceramic-based inks fused to the glass during tempering, they differ significantly in terms of application, cost-effectiveness, and design complexity.

| Feature | Ceramic Frit (Screen Printed) | Digital Ceramic Printed Glass |

|---|---|---|

| Process | Ink is pushed through a mesh stencil (silk-screen). | Ink is "jetted" directly onto glass (inkjet technology). |

| Design Flexibility | Best for simple patterns (dots, lines, solid bands). | Best for complex graphics, photos, and gradients. |

| Color Depth | Thicker ink layer; high opacity and vibrancy. | Thinner layer; better for transparency/layering. |

| Color Limits | Usually limited to 1–4 colors per pane. | Unlimited colors (Full CMYK spectrum). |

| Cost Efficiency | Low cost for high-volume identical panels. | Low cost for short runs or custom designs. |

| Setup Time | High (screens must be custom-made). | Low (file is sent directly from computer). |

| Resolution | Lower; limited by the mesh of the screen. | High; photo-realistic quality (up to 720+ DPI). |

| Durability | Permanent; scratch, UV, and weather resistant. | Permanent; scratch, UV, and weather resistant. |

Different Application of Dots Ceramic Frit Glass

- Skylights- High safety and nice view.

- Roofs-Easy to clean and maintain, durable and long-term without replacement, very safe

- Exterior walls-Unique exterior wall decoration function, supporting very high customization

- Ceramic frit spandrel glass – Very good decorative effect, hiding the wall thickness and other fixing materials, making the overall appearance

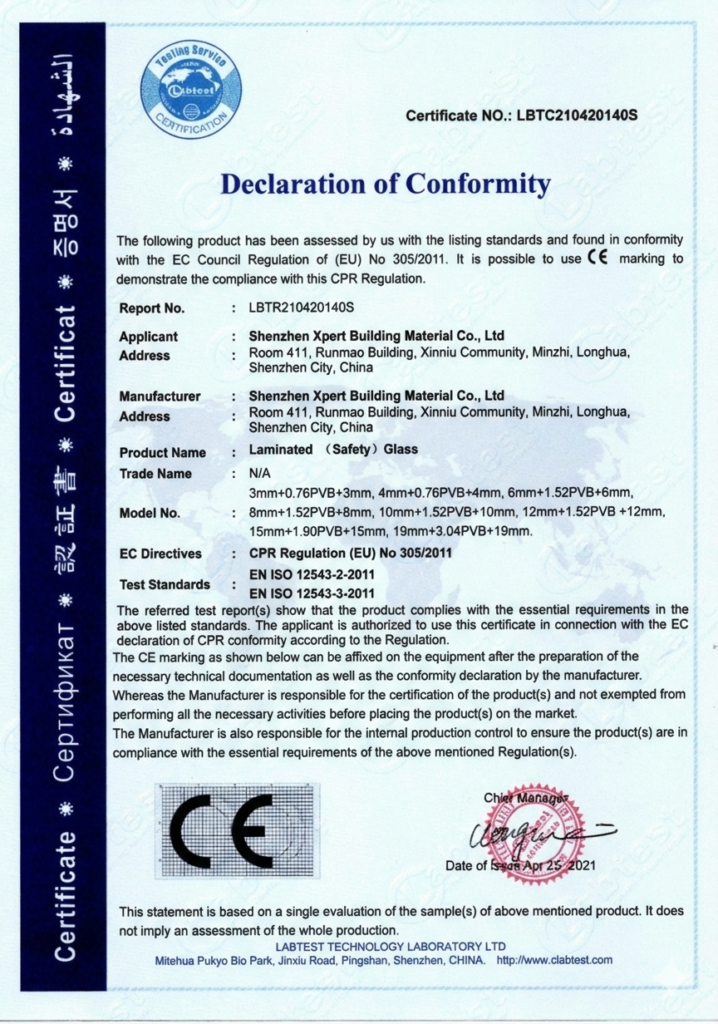

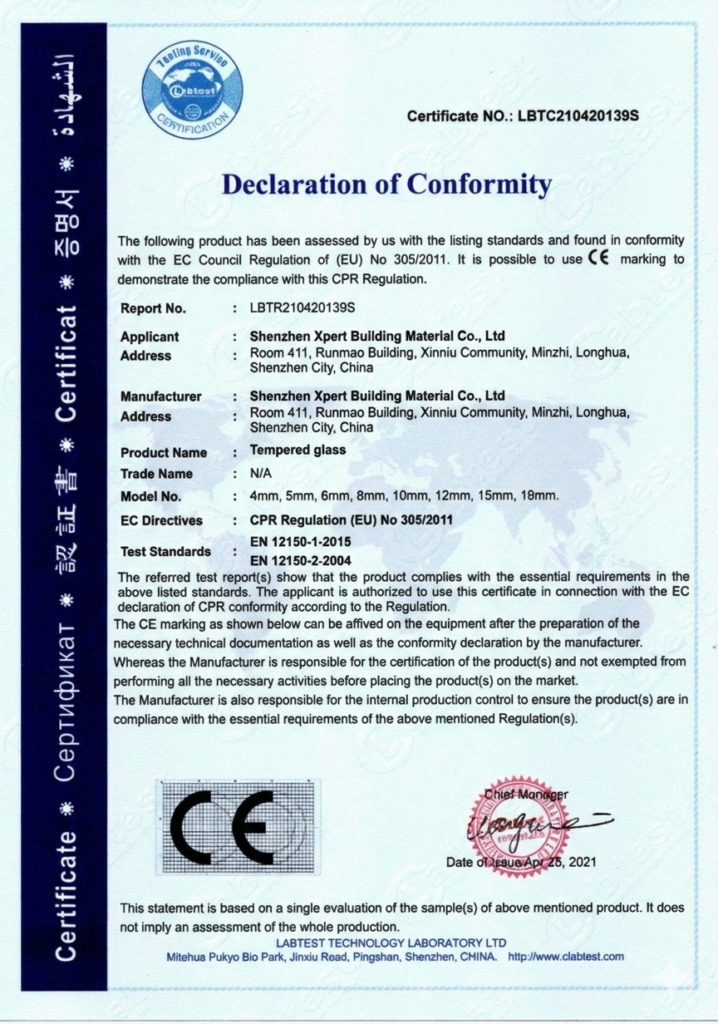

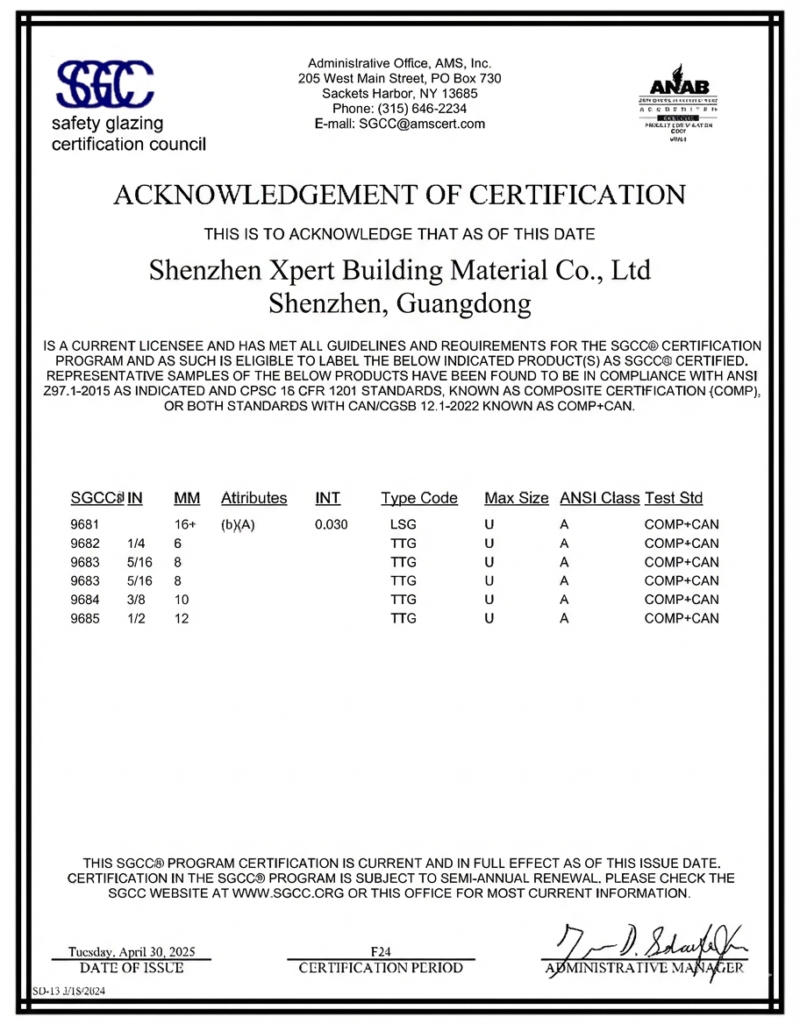

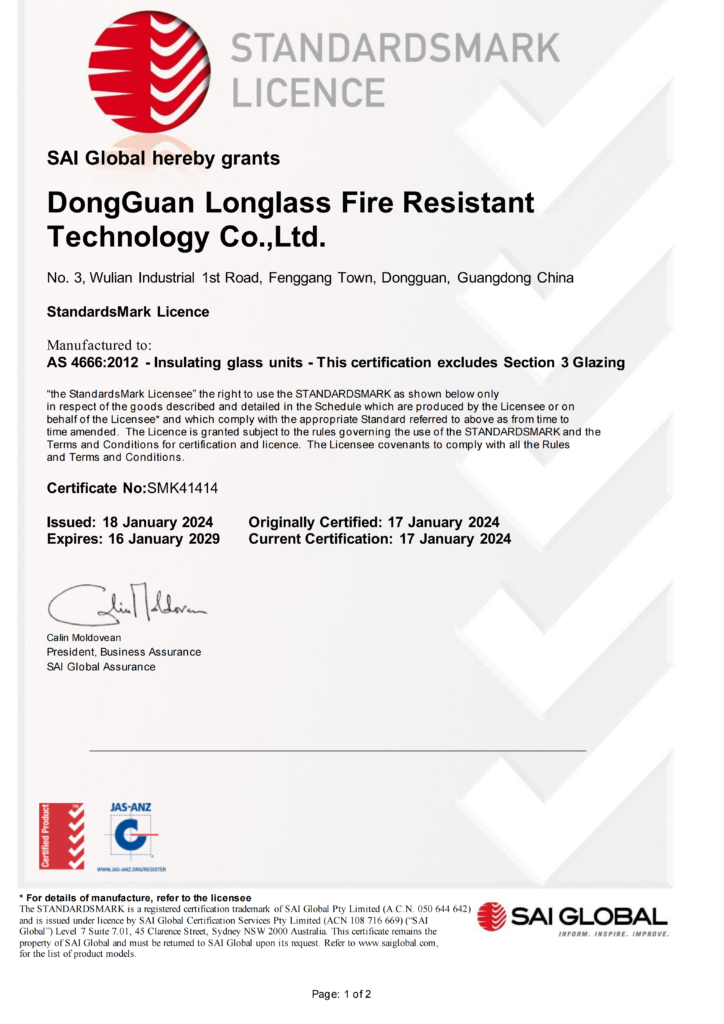

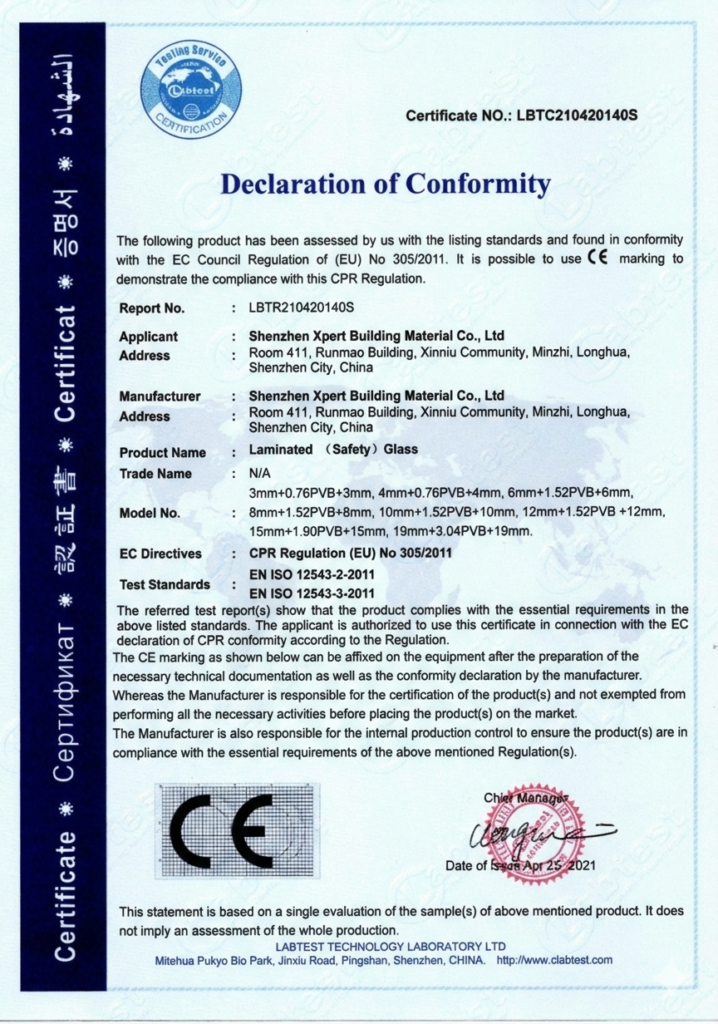

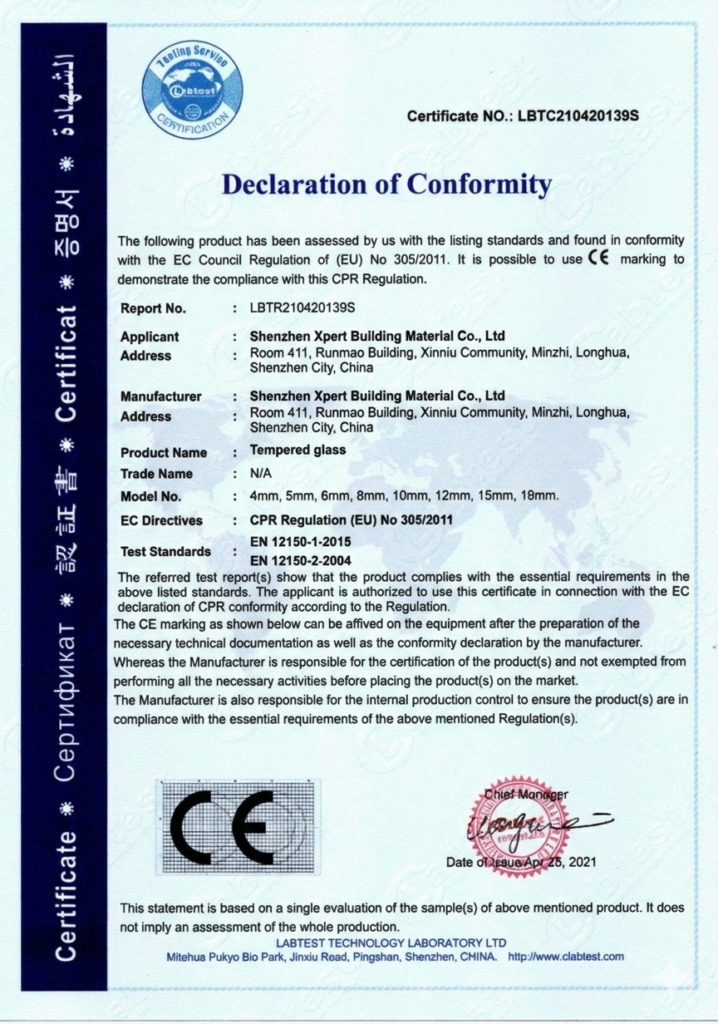

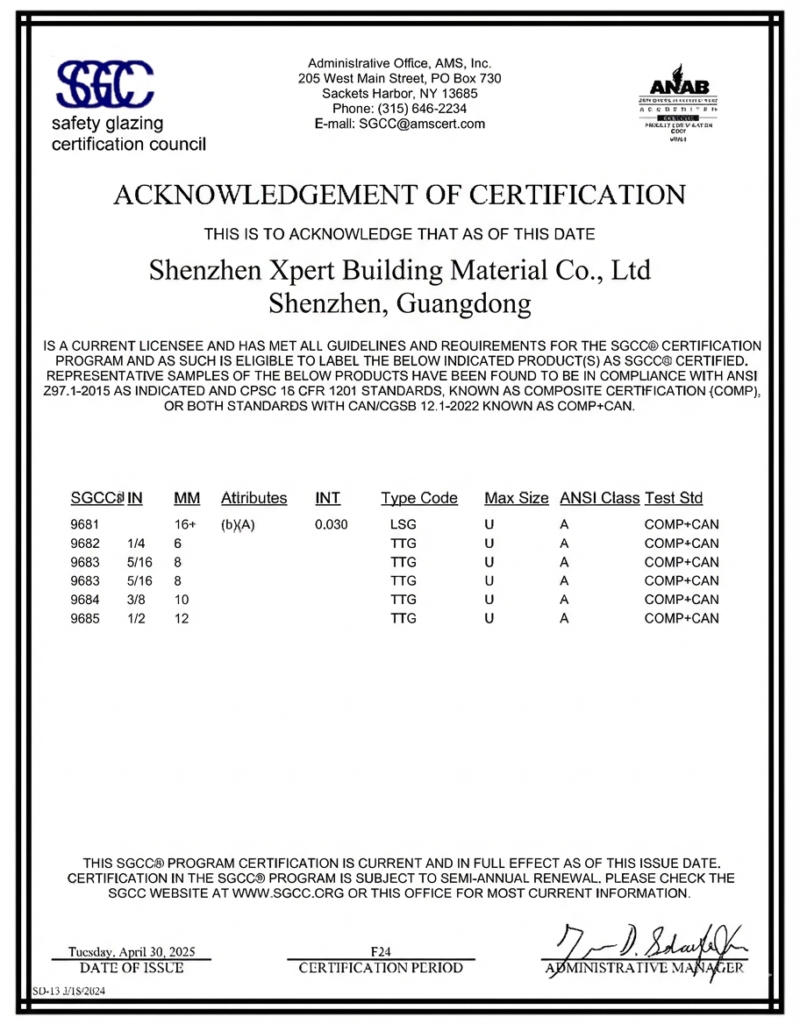

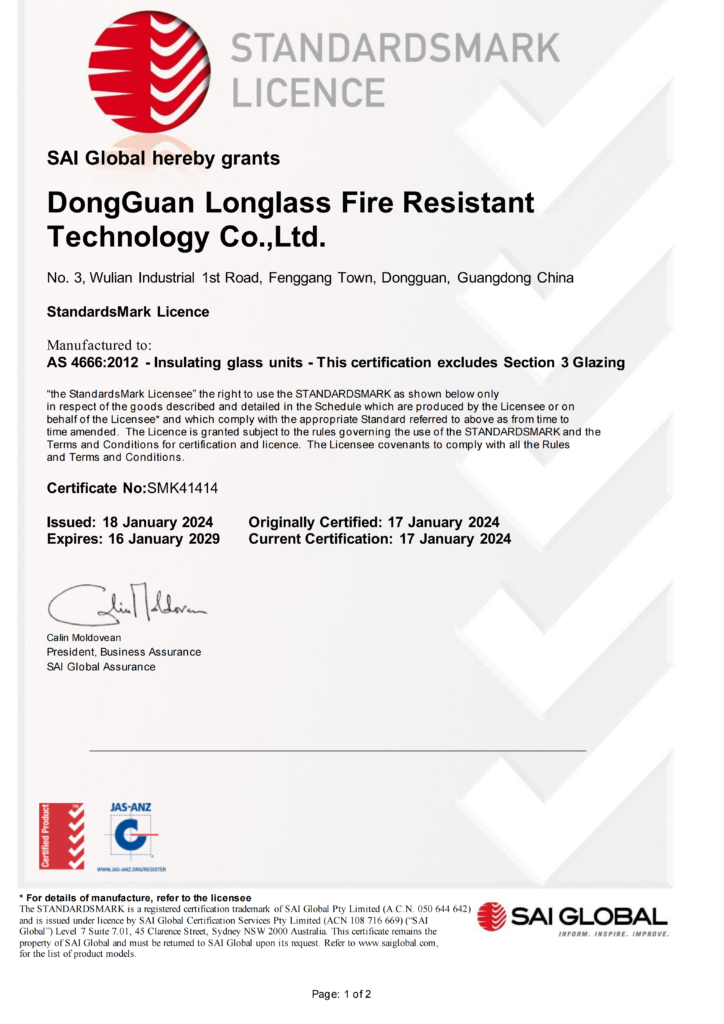

Certification for Ceramic Frit Glass

Packing Informarion for Ceramic Frit Glass

Strong Plywood Crates with steel straps for secure transport.

Moisture-Proof Wrapping to protect against humidity during shipping.

Rubber Padding to prevent edge chipping.

Suitable for LCL (Less than Container Load) and FCL (Full Container Load) shipments.

We supply a wide range of silk-screen ceramic frit glass designs, including lines, grids, dots, and custom graphics.

📩 Contact us today for free samples, custom printing options, and competitive bulk pricing tailored to your project.

FAQs for Order Dots Ceramic Frit Glass

Unlike organic inks used in some digital printing, Ceramic Frit Glass uses inorganic mineral pigments that are fused into the glass surface at temperatures exceeding 600°C during the tempering process. This creates a permanent bond, making the pattern virtually immune to UV radiation, scratching, and chemical corrosion. For exterior facades (curtain walls), ceramic frit is the industry gold standard because it will not peel or fade over the building’s 30+ year lifespan.

The dots are not just decorative; they act as a functional solar screen. By adjusting the opacity and density of the frit pattern, you can significantly lower the Solar Heat Gain Coefficient (SHGC). High-density dot patterns reflect a portion of solar energy before it enters the interior, reducing cooling loads and glare while still maintaining natural light transmission and visibility for occupants.

No. Because the ceramic frit process is integrated with thermal toughening (tempering), the glass cannot be cut, drilled, or edge-worked once it has been fired. All customizations, including holes for spider fittings or specific edge polishing, must be completed in the fabrication stage prior to the silk-screening and tempering process to ensure structural integrity.

Yes, it can be. According to bird-safe building standards, patterns like our ceramic dots (when spaced according to the “2×4 rule” or similar guidelines) break up reflections on the glass surface. This allows birds to perceive the glass as a solid barrier, significantly reducing avian collisions—a growing requirement for LEED certification and modern urban building codes.

We can provide panels up to 2440mm x 9000mm. For color precision, we utilize the Pantone or RAL color matching systems. However, it is important to note that the base glass tint (Clear vs. Low-Iron) will slightly affect the final appearance. For the most vibrant white or light-colored patterns, we recommend using Low-Iron (Extra Clear) glass to eliminate the natural greenish tint of standard float glass.

Send Your Request