5+9A+5mm Double Glazing for Container Homes-Cost Effective Options for Future House

5+9A+5mm Double Glazing for Container Homes-Cost Effective Options for Future House

Upgrade your prefab project with Xpert Building Material’s double glazing for container homes. Our 5+9A+5mm tempered units offer:

-

Superior Insulation: Drastically reduces HVAC energy consumption.

-

Safety First: High-impact tempered safety glass for secure living.

-

Modular Ready: Ideal for foldable container houses and rapid-deploy structures.

-

Professional Support: Fast response and reliable shipping from a trusted prefab house glass windows supplier. Maintain a comfortable interior regardless of external weather with our industry-standard glazing solutions.

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

Insulating Glazing Unit

The global housing market is undergoing a radical shift. As traditional brick-and-mortar construction becomes increasingly expensive and time-consuming, modular solutions are stepping into the spotlight. Among these, the container home has evolved from a niche architectural experiment into a mainstream sustainable housing solution. However, the primary challenge of living in a steel box is temperature regulation. This is where high-specification glass becomes the most critical component of the build.

If you are a developer or a DIY enthusiast, choosing the right double glazing for container homes isn’t just about aesthetics—it’s about making a steel structure livable. Specifically, the 5+9A+5mm configuration has emerged as the “sweet spot” for balancing cost, weight, and thermal performance.

What is 5+9A+5mm Double Glazing for Container Homes?

To the uninitiated, glass nomenclature can seem like a secret code. When we talk about 5+9A+5mm double glazing, we are describing a sandwich-like structure designed to combat the inherent thermal conductivity of modular steel frames.

The 5mm Layers: These are two panes of high-quality glass (usually tempered for safety). At 5mm thick, they provide enough structural rigidity to withstand wind loads and physical impact without adding the excessive weight that can complicate the transport of a foldable container house.

The 9A Spacer: The “A” stands for “Air” (or Argon). This is a 9mm hermetically sealed gap between the two panes. This pocket of gas acts as a thermal break. Because air is a poor conductor of heat, it prevents the scorching summer sun or the biting winter cold from transferring directly into the living space.

For those looking for a prefab house glass windows supplier, this specific configuration is often the gold standard. It provides a significant upgrade over single-pane glass while remaining more affordable and lighter than triple-glazed units, which can often be “overkill” for the structural frames of standard shipping containers.

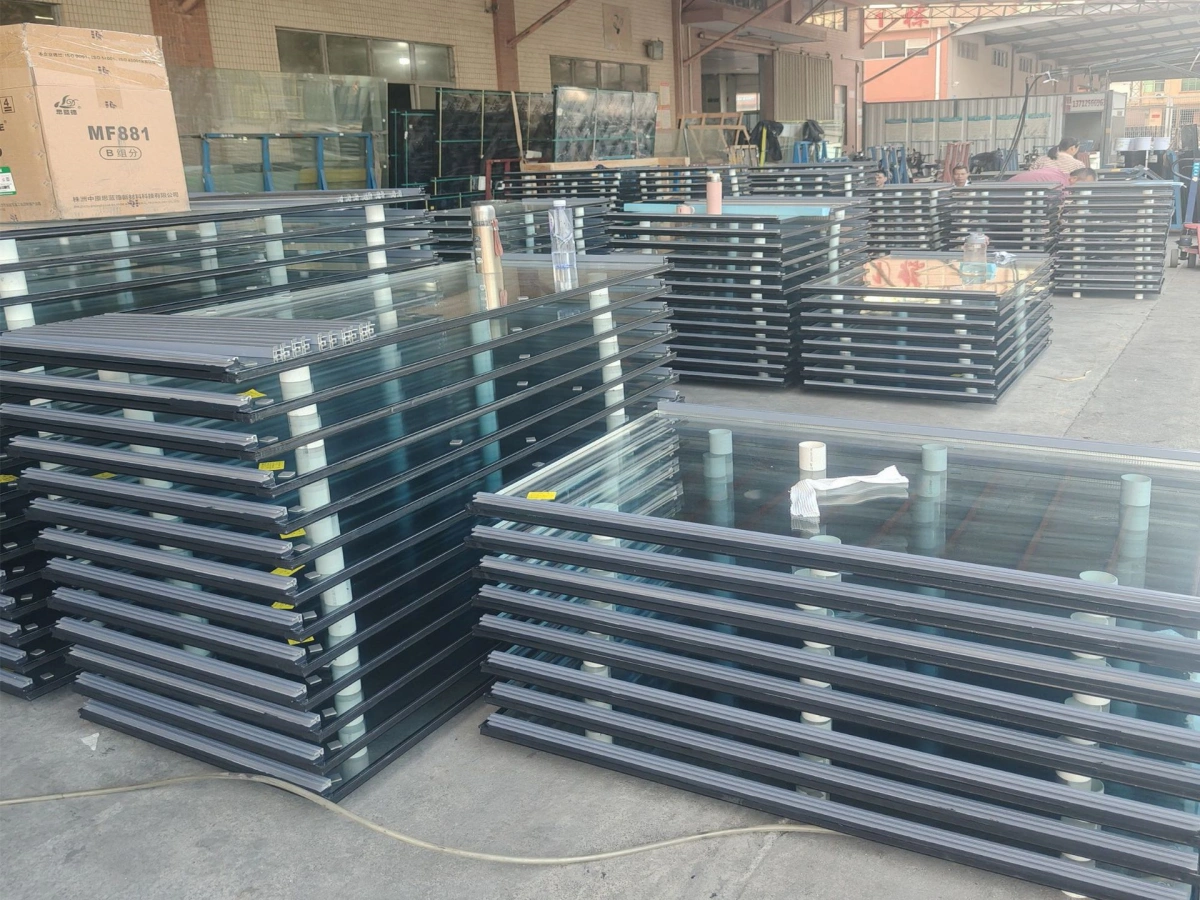

Working Flow of Double Glazing for Container Homes

Why Choose 5+9A+5mm Double Glazing for Container Homes from Xpert Building Material?

In the building material industry, a product is only as good as the supply chain behind it. At Xpert Building Material, we don’t just move crates; we solve the logistical and technical bottlenecks that often plague modular construction projects.

Feedback from Our Global Partners

Our long-term partners—ranging from modular housing developers to tiny-home builders in the world—consistently cite our reliability as their primary reason for staying. They don’t just need glass; they need a partner who understands that a two-week delay in a window shipment can stall an entire housing assembly line.

Rapid-Response Culture

In the fast-paced world of modular buildings, questions about U-values, light transmission, or custom sizing need answers immediately. Our technical team is trained to provide rapid responses, ensuring that your project’s planning phase isn’t bogged down by communication gaps.

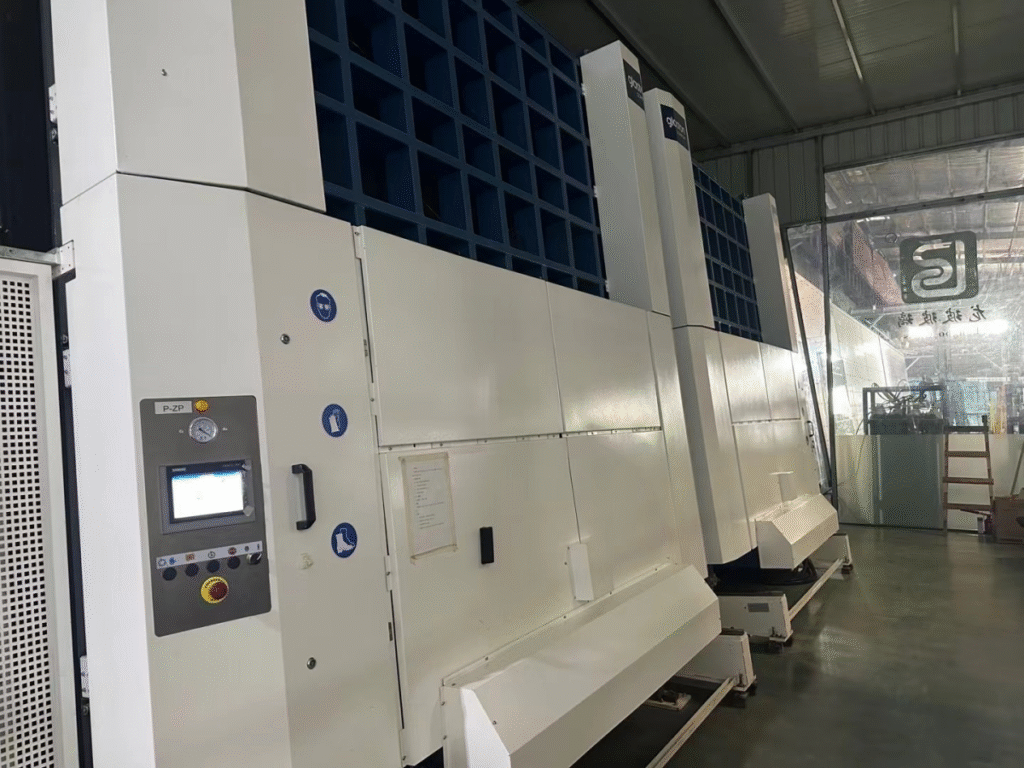

A Stable and Resilient Supply Chain

The volatility of raw material costs can be a nightmare for project budgeting. Xpert Building Material maintains deep, stable relationships with raw glass manufacturers. This allows us to offer consistent pricing and, more importantly, consistent quality. You won’t see variations in glass clarity or spacer durability from one batch to the next.

Fast Delivery for Tight Deadlines

Time is the greatest asset in prefab construction. We have optimized our manufacturing and loading processes to ensure that our energy efficient glass for modular buildings reaches your site or factory exactly when you need it. By minimizing lead times, we help you maintain a high turnover rate for your container home inventory.

Features for 5+9A+5mm Double Glazing for Container Homes

When selecting tempered safety glass for modular buildings, it is important to look beyond the surface. Our 5+9A+5mm units are engineered with several specific advantages:

Superior Thermal Insulation: By creating a dead-air space, these units significantly lower the U-value of your windows. This means lower electricity bills for the end-user, as HVAC systems don’t have to work overtime to fight the external climate.

Acoustic Dampening: Container homes are often used in urban environments or as roadside offices. The dual-pane system provides an effective barrier against high-frequency noise, turning a noisy exterior into a peaceful interior.

Enhanced Safety and Security: We use high-strength tempered glass. In the rare event of a breakage, the glass shatters into small, blunt cubes rather than dangerous shards. This is non-negotiable for glazing for foldable container houses that may experience vibration during transport.

Condensation Control: Standard single-pane glass in a steel container is a magnet for “sweating.” Our double-glazed units feature high-grade desiccants within the spacer bars to absorb any internal moisture, ensuring clear views and preventing mold growth around window frames.

UV Protection: Our glass coatings help filter out harmful ultraviolet rays, protecting the interior flooring and furniture of the container home from fading over time.

Specification for 5+9A+5mm Double Glazing for Container Homes

| Feature | Specification Details |

| Glass Thickness | 5mm Outer + 9mm Air Gap + 5mm Inner |

| Glass Type | Fully Tempered / Toughened Safety Glass |

| Spacer Material | Aluminum or Warm Edge Spacer (Optional) |

| Gas Filling | Dry Air or Argon Gas (for enhanced insulation) |

| U-Value | Approx. 2.7 – 1.6 W/m²K (Depending on Low-E coatings) |

| Visible Light Transmittance | 70% – 82% |

| Solar Heat Gain Coefficient (SHGC) | 0.45 – 0.70 |

| Sound Insulation | 30 – 35 dB |

| Size Capability | Custom sizes tailored to container apertures |

| Sealant Type | High-durability Butyl (Primary) & Silicone (Secondary) |

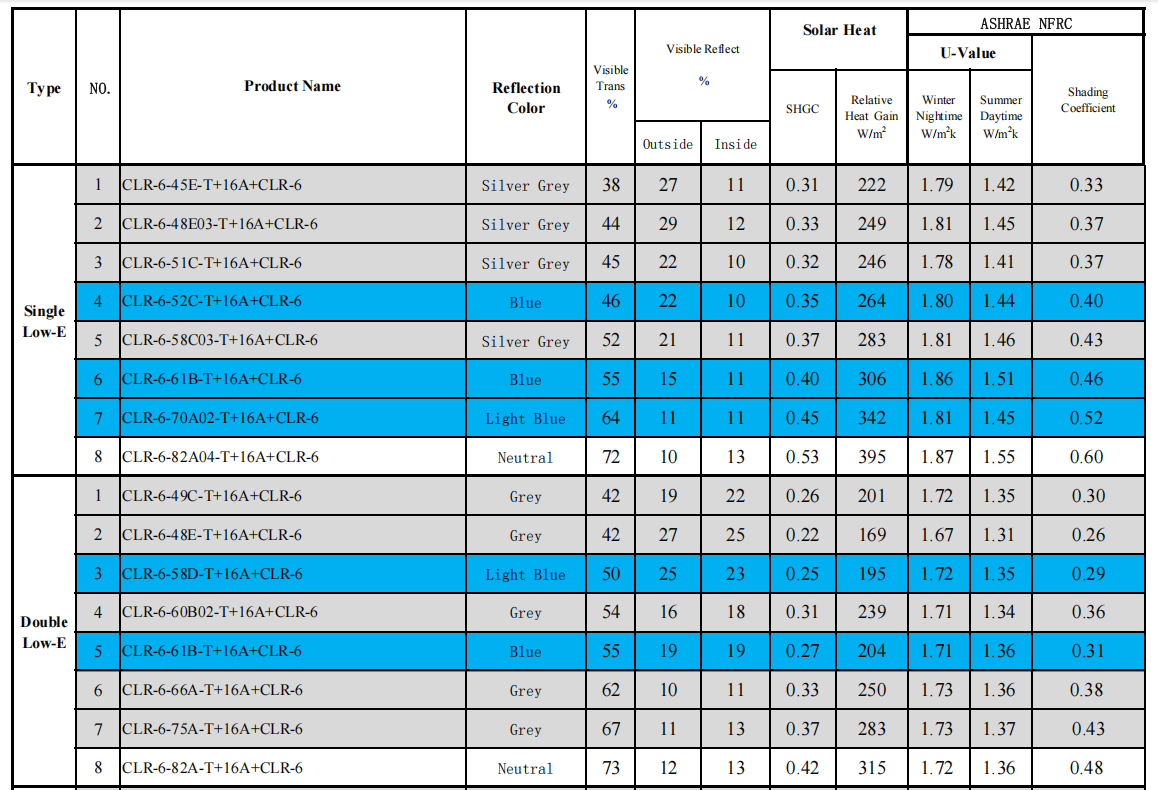

Solar Performance Data Reference for Dual Pane Insulating Unit

Safety Packages Information for Double Glazing for Container Homes

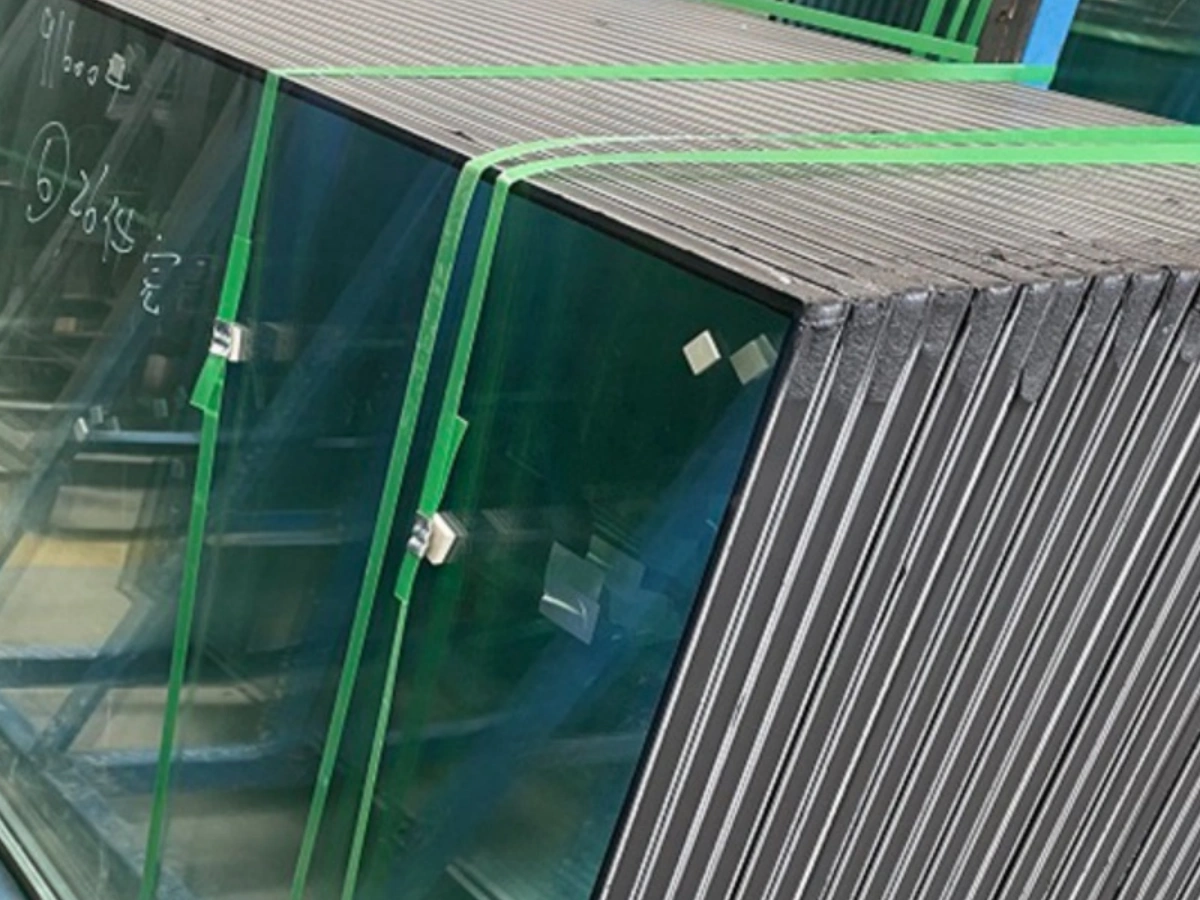

Shipping glass globally requires more than just a “fragile” sticker. Because we are a primary prefab house glass windows supplier, we have perfected the art of the “Zero-Damage” shipment.

Custom Wooden Crates: We use fumigated, high-strength plywood crates designed to be handled by forklifts and cranes.

End-Cap Protection: Each glass unit is separated by cork pads or plastic spacers to prevent surface scratches and friction during sea transit.

Moisture-Proof Wrapping: Crates are wrapped in industrial-grade stretch film and often include desiccant bags to prevent “glass cloudy” issues caused by humidity in shipping containers.

Reinforced Loading: We utilize specialized bracing techniques within the shipping container to ensure that the crates cannot shift, even during rough seas or sudden logistical movements.

If you are looking for a reliable, expert-level prefab house glass windows supplier, Xpert Building Material is ready to assist. We provide the technical clarity and logistics support required to make your modular project a success.

Contact Us Today:

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

FAQs for 5+9A+5mm Double Glazing for Container Homes

No. While it is heavier than single-pane glass, a standard 20ft or 40ft container frame is more than capable of supporting these units. In fact, the added rigidity of the tempered glass can help with the overall feel of the window opening.

Absolutely. We highly recommend a Low-E (Low-Emissivity) coating for container homes located in extreme climates. This further reduces heat transfer without significantly affecting the amount of natural light entering the home.

While a 12mm or 16mm gap offers slightly better thermal insulation, the 9mm gap is the preferred choice for container homes because it allows for a slimmer window profile. This is crucial when you are trying to maximize every inch of interior floor space.

We use a dual-seal system (primary butyl and secondary silicone/polysulfide). This industrial-grade sealing process is designed to last 20+ years, preventing the “fogging” that occurs when seals fail.

We can provide custom CNC-cut shapes, including circular or trapezoidal windows, to fit unique architectural designs in modern modular buildings.

Typically, our production lead time is 15-25 days depending on the complexity of the order. We prioritize a stable supply chain to ensure we meet your construction milestones.

Very much so. The 5+9A+5mm configuration breaks the sound wave as it passes through different densities (glass-air-glass), which is far more effective than a single 10mm pane of glass.