Premium Monolithic 60-120 Minutes Fire Resistant Glass Panel from Xpert BM-Secure Your Supply Chain

Premium Monolithic 60-120 Minutes Fire Resistant Glass Panel from Xpert BM-Secure Your Supply Chain

Product: Monolithic 60-120 Minutes Fire Resistant Glass

Thickness: 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm

Color: Clear, Low iron, tinted, Low E.

Size: Customized, 3300x10000mm

Application: door, window, partition wall, exterior wall, facade, etc.

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 Square Meters

Supply Ability: Over 7000 Square Meter / Day

Country of Origin: China

Lead Time: 15 Days

Payment Term: Bank Wire Transfer

Require more details about the monolithic 60-120 minutes fire tesistant glass price, let us know anytime! sales@xpertglazing.com or WhatsApp +86 15711964309

Fire Resistant Glass

In the world of high-end construction and architectural safety, glass is no longer just a window to the outside world. It is a critical component of a building’s life-safety system. When we talk about 60-120 Minutes Fire Resistant Glass Panel, we are entering a territory where engineering meets life preservation.

Specifically, monolithic fire-rated glass represents a significant leap forward. Unlike traditional thick, multi-layered laminated fire glass, monolithic glass consists of a single, specially toughened or chemically enhanced pane. At Xpert Building Material, we provide cutting-edge monolithic solutions that offer the highest level of integrity while maintaining the sleek, minimalist aesthetic that modern architects crave.

What is Monolithic 60-120 Minutes Fire Resistant Glass Panel?

To understand monolithic fire-rated glass, you first have to understand the “Integrity” (Class E) requirement. While some fire glass is designed to block heat (Insulation), monolithic glass is primarily engineered to block flames, smoke, and toxic gases.

The Science of the Single Pane

Standard tempered glass will shatter almost immediately when exposed to the 1,000°C+ temperatures of a structural fire. Monolithic Fire Resistant Glass is different. It is typically manufactured using high-borosilicate glass or through a specialized physical and chemical tempering process that alters the glass’s molecular structure.

60 Minutes Fire Rated Glass: A standard for most commercial corridors and office partitions. It provides a solid hour of protection, allowing occupants to evacuate safely.

90 Minutes Fire Rated Glass: Used in more critical areas like stairwells and elevator lobbies where exit times might be longer.

120 Minutes Fire Rated Glass: The “Gold Standard” of integrity. This glass stays in its frame for two full hours under intense heat, acting as a massive shield against the spread of a conflagration.

Because it is monolithic (single-layered), it doesn’t have the “milky” look or the weight of traditional fire glass. It is clear, light, and incredibly tough.

Processing Flow for 60-120 mins Fire Resistant Glass Panel

Why Choose 60-120 Minutes Fire Resistant Glass Panel from Xpert Building Material?

In an industry where a single shipment delay can stall a multi-million dollar project, who you buy from matters as much as what you buy. Xpert Building Material has built a reputation on being more than just a vendor; we are a strategic partner.

Insights from Our Partners

We work closely with facade engineers and safety consultants across the globe. Our partners often tell us that the “Xpert Difference” lies in our technical honesty. If a specific fire rating isn’t achievable with a certain frame, we tell you upfront. This transparency has built long-term trust in the building materials industry.

Fast Response and Technical Precision

We don’t believe in automated, “one-size-fits-all” responses. When you inquire about fire rated glass doors or custom partitions, our team analyzes your local fire codes and provides a tailored quote within 24 hours. We understand the pressure of deadlines.

A Stable and Resilient Supply Chain

Global logistics can be a nightmare. However, Xpert Building Material has invested heavily in raw material stockpiling and modernized production lines. While other suppliers might quote 12-week lead times due to “market shortages,” our stable supply chain ensures that your 120 minutes fire rated glass is ready when the project hits the glazing phase.

Fast Delivery – Worldwide

Whether your project is in America, Europe, the Middle East, or Southeast Asia, we have the logistics network to get glass to your site safely. We prioritize “Green Channel” shipping routes and handle the complex documentation required for international glass transport, ensuring your project stays on track.

Key Features of Monolithic Fire Resistant Glass Panel

Why choose monolithic over laminated? Here are the features that make our glass the preferred choice for safety engineers:

Exceptional Optical Clarity: Laminated fire glass often has a slight tint or “haziness” due to the intumescent layers. Our monolithic glass is as clear as high-quality float glass.

Reduced Weight: Being a single pane, it is significantly lighter than multi-layered alternatives. This means less stress on the hinges of your fire rated glass doors and lower shipping costs.

UV and Weather Resistance: Monolithic glass doesn’t have an interlayer that can turn yellow or delaminate when exposed to the sun. It is perfect for both interior and exterior applications.

High Impact Resistance: Beyond fire safety, our glass is also a high-performance safety glass, designed to resist impact and prevent injury in high-traffic areas.

Temperature Tolerance: It can withstand a thermal shock of up to 250°C – 300°C, whereas standard glass fails at around 40°C.

Specifications for Monolithic Fire Resistant Glass Panel

Below is a technical breakdown of our monolithic fire-rated glass offerings. These specs are designed to help architects integrate our products into their BIM models and project plans.

| Technical Parameter | 60 Minutes Rating | 90 Minutes Rating | 120 Minutes Rating |

| Glass Type | Monolithic (E60) | Monolithic (E90) | Monolithic (E120) |

| Available Thickness | 6mm, 8mm, 10mm | 10mm, 12mm | 12mm, 15mm |

| Max Dimensions (mm) | 2400 x 4200 | 2000 x 3000 | 1800 x 2800 |

| Visible Light Trans. | 89% – 91% | 88% – 90% | 87% – 89% |

| Weight (kg/m²) | 15 – 25 | 25 – 30 | 30 – 37.5 |

| Fire Class | Integrity (E) | Integrity (E) | Integrity (E) |

| Standard Testing | BS EN 1634 / UL 10C | BS EN 1634 | BS EN 1634-1 |

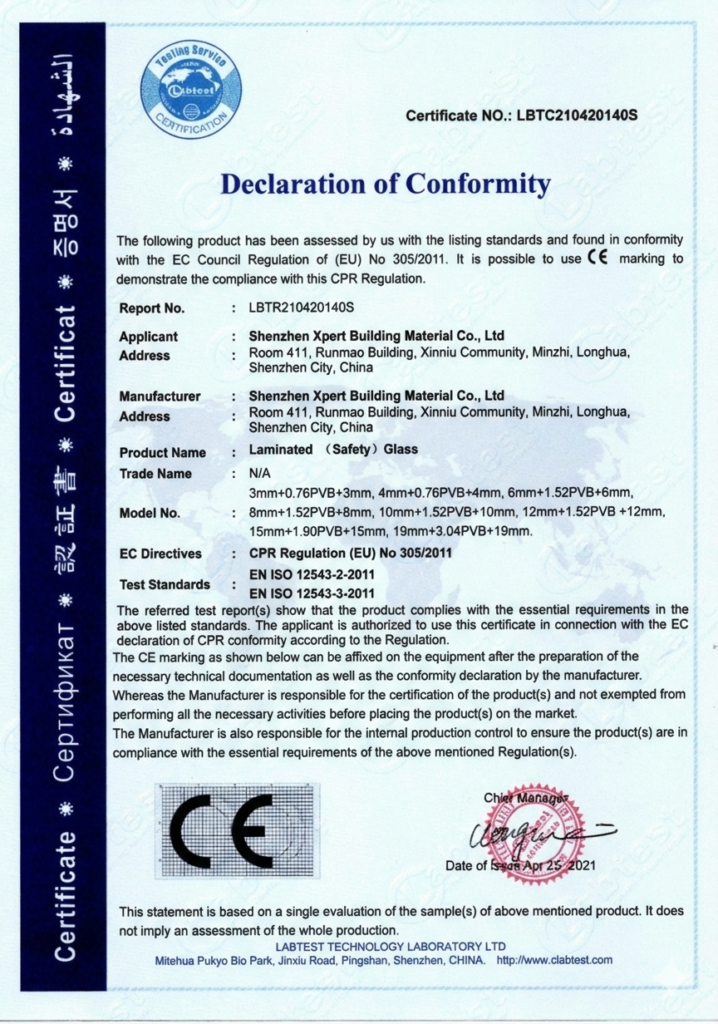

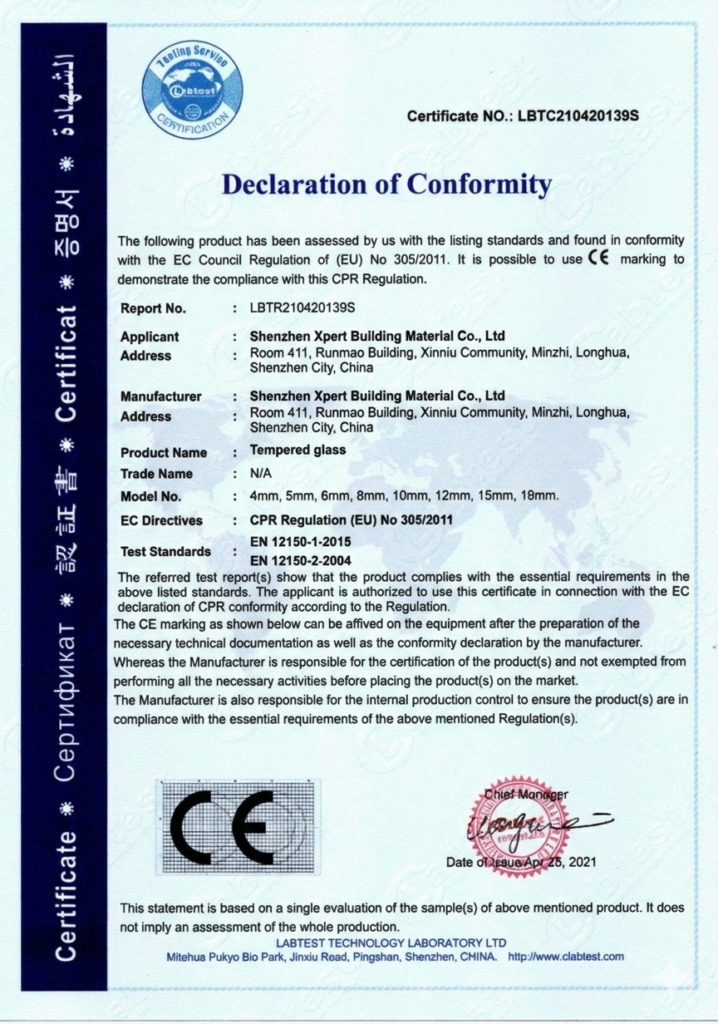

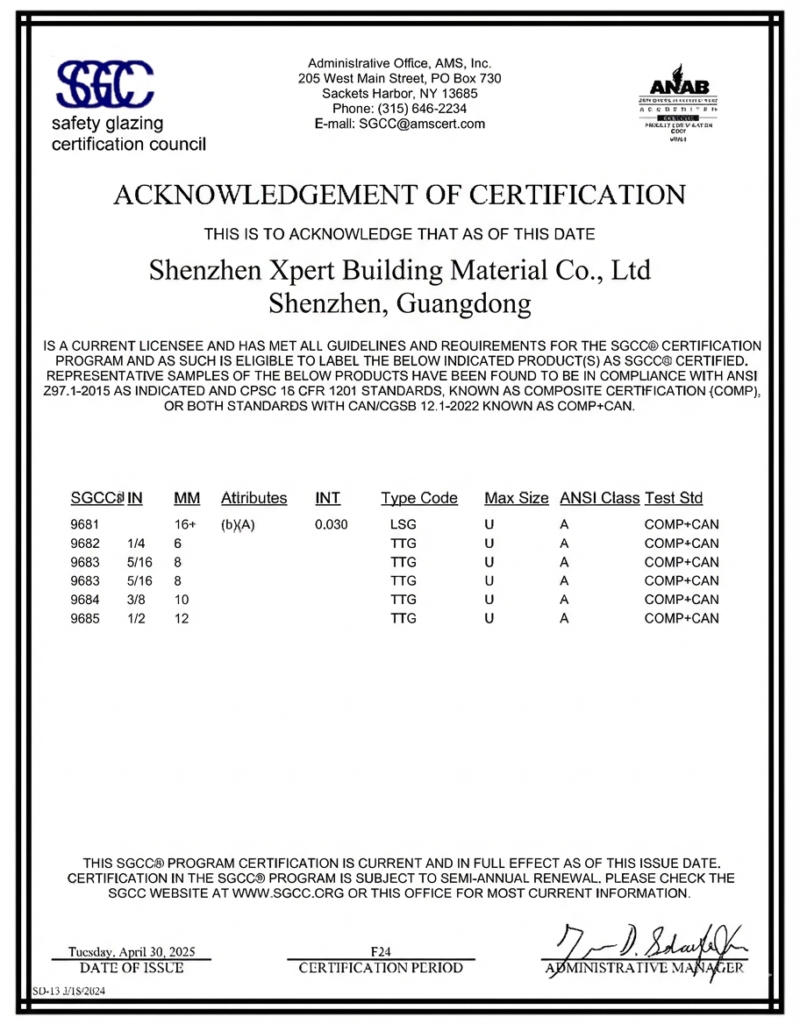

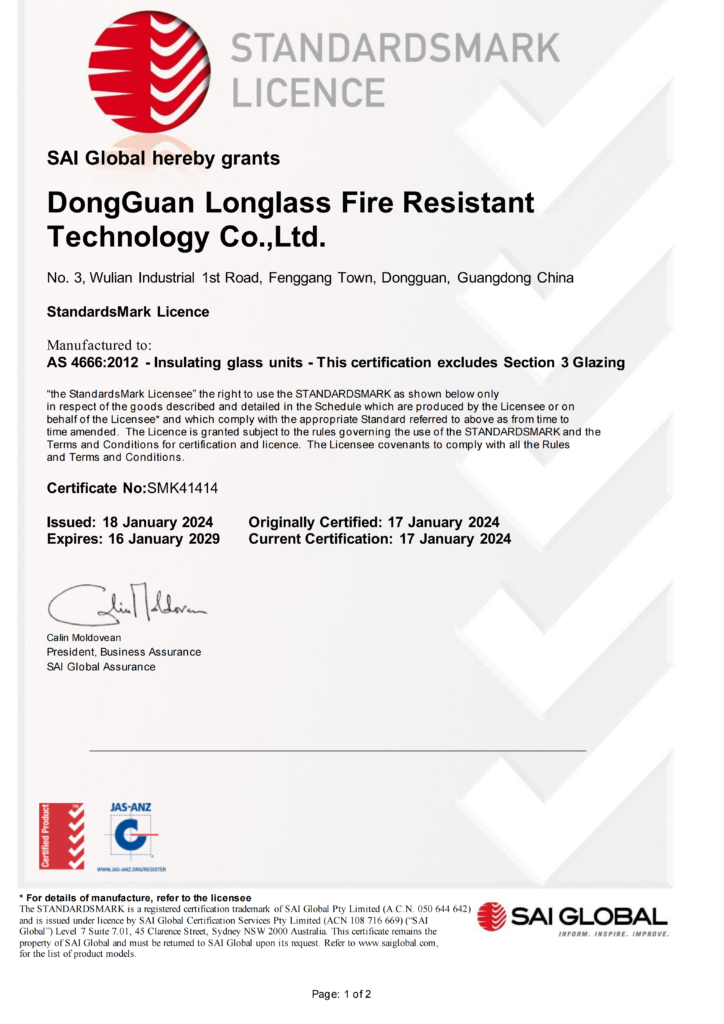

Certification for Toughened Fire Resistant Glass Panel

Applications for Monolithic Fire Resistant Glass Panel

The versatility of monolithic glass allows it to be used in places where traditional, heavy fire glass would be impractical.

High-Performance Fire Rated Glass Doors

Modern offices use glass doors to promote an open-door culture and maximize light. Our fire rated glass doors utilizing 60-minute monolithic glass offer a sleek, frameless look while ensuring that the door remains a barrier against smoke and fire.

Curtain Walls and External Facades

Because monolithic glass is resistant to UV radiation and moisture, it is the ideal choice for exterior windows in buildings that are located close to property lines (where fire ratings are often required by code).

Hospital and School Partitions

In public buildings, visibility is safety. Monolithic partitions allow security personnel to see through a building during an emergency, while still containing any fire within its zone of origin.

Smoke Screens and Baffles

In large shopping malls or atriums, monolithic glass is often used as a smoke baffle—a hanging glass pane that prevents smoke from moving horizontally across a ceiling, funneling it instead toward smoke vents.

Safety Packaging and Global Shipping Information

Transporting glass—especially large panes of 120 minutes fire rated glass—is a high-stakes task. We don’t take shortcuts.

Industrial A-Frame Crating: We use custom-built, heavy-duty wooden A-frames that keep the glass upright and stable.

Protective Cork Pads: Every sheet of glass is separated by high-density cork or rubber pads to prevent friction-induced scratches and “suction” between panes.

Moisture-Proof Wrapping: Each crate is wrapped in a heavy-duty, waterproof polymer shroud to protect the glass from salt air and humidity during ocean transit.

Impact Monitoring: For large-scale projects, we include “Tip-N-Tell” or “ShockWatch” sensors on the crates. This provides a transparent record of how the glass was handled during its journey to your site.

When you are responsible for the safety of a building’s occupants, you need a glass supplier that takes that responsibility as seriously as you do. Xpert Building Material is committed to providing the highest quality Fire Resistant Glass with the logistical support to make your project a success.

Don’t settle for “good enough” when it comes to fire safety. Get the clarity, strength, and reliability of monolithic fire-rated glazing.

Get a Quote Within 24 Hours

Email us: sales@xpertglazing.com

WhatsApp our technical team: +86 15711964309

FAQs for Monolithic Fire Resistant Glass Panel

The main advantages are weight and thickness. Monolithic glass is much thinner and lighter, making it easier to install in standard door frames. It also lacks the chemical interlayers that can sometimes cloud or yellow over time.

Monolithic glass is generally rated for “Integrity” (Class E). This means it blocks flames and smoke. While it is incredibly heat-resistant and won’t break, it does allow radiant heat to pass through. If your building code requires “Insulation” (Class EI) to keep the non-fire side cool, you may need a specialized version or an IGU (Insulated Glass Unit) configuration.

Only if the wooden frame itself is fire-rated and the entire system has been tested together. Fire safety is about the assembly (glass, frame, and sealant), not just the glass pane.

Monolithic fire-rated glass is a type of safety-tempered glass. Like all tempered glass, it cannot be cut, drilled, or edged after the tempering process. All dimensions must be finalized before production.

Borosilicate glass contains boron trioxide, which has a very low coefficient of thermal expansion. This means when one side of the glass is 800°C and the other is 20°C, the glass doesn’t expand unevenly and crack. This is what allows it to reach a 120 minutes fire rated glass status.

Yes. We can manufacture monolithic fire glass with various coatings to improve energy efficiency or reduce solar heat gain, provided it doesn’t interfere with the fire-rating integrity.