Custom 10mm Toughened Table Top Glass: Safety and Durability Choices

Custom 10mm Toughened Table Top Glass: Safety and Durability Choices

Product: CE Certified 8mm Toughened Table Top Glass

Thickness: 8mm, 5/16

Color: Clear, low-iron, tinted, ceramic frit or acid-etched

Size: Customized, 2140x3300mm

Application: table top for exterior or interior

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 Square Meters

Supply Ability: Over 7000 Square Meter / Day

Country of Origin: China

Lead Time: 15 Days

Payment Term: Bank Wire Transfer

Require more details about the 8mm toughened table top glass price, let us know anytime! sales@xpertglazing.com or WhatsApp +86 15711964309

Table Top Glass

What is 10mm Toughened Table Top Glass?

When we refer to 10mm toughened table top glass, we mean a specialized safety glass that has undergone a rigorous thermal tempering process. To the naked eye, it may look no different from regular glass, but its internal structure is fundamentally different. The glass is heated to approximately 620 °C and then rapidly cooled using high-pressure air—a process known as quenching. This creates compressive stress on the surface while the interior remains under tension.

A 10 mm thickness toughened glass is widely regarded as the “golden thickness” for furniture applications. It is heavy and stable enough to sit securely in place without the need for special adhesives, yet slim enough to maintain a sleek, modern aesthetic. Whether used for tempered glass for a table in high-traffic conference rooms or as a decorative element in minimalist living spaces, its strength can reach up to five times that of standard annealed glass.

“Toughened” does not simply mean shatter-resistant; more importantly, it refers to how the glass behaves upon impact. Unlike regular glass, which breaks into dangerous, sharp shards, tempered glass crumbles into small, relatively blunt granules when shattered. This inherent safety feature is precisely why it has become an industry standard for interior designers and architects.

Processing Flow for 10mm Toughened Table Top Glass

Why Choose 10mm Toughened Table Top Glass from Xpert Building Material?

In the building material industry, a product is only as good as the supply chain behind it. At Xpert Building Material, we don’t just sell glass; we provide a partnership that ensures your projects move forward without friction.

Insights from Our Cooperated Partners

Our long-term partners—ranging from high-end furniture manufacturers to commercial property developers—consistently cite our reliability as their primary reason for staying with us. They need a supplier who understands that a delay in a glass shipment can stall an entire interior fit-out. We’ve built our reputation on being the backbone of their production schedules.

Fast Response and Technical Support

We live in a fast-paced market. When you send an inquiry about a made tempered glass table or a custom bulk order, you don’t want to wait days for a quote. Our team is trained to provide rapid, technically accurate responses. Whether you are asking about tolerance levels or edge polishing types, we give you the answers you need to make an informed decision immediately.

A Stable and Resilient Supply Chain

Global logistics can be volatile, but Xpert Building Material has invested heavily in a stable supply chain. We source premium raw float glass and manage the tempering process in-house or through strictly vetted facilities. This vertical integration allows us to maintain quality control from the moment the sand is melted until the glass is crated.

Fast Delivery and Global Reach

We understand that “time is money.” By optimizing our production queues and partnering with Tier-1 shipping carriers, we ensure that your 10mm toughened table top glass arrives on site exactly when promised. Our packaging is designed for the rigors of international transit, ensuring zero-defect delivery across borders.

Features of 10mm Toughened Table Top Glass

Choosing the right material requires understanding its unique characteristics. Here is what sets our 10mm glass apart:

High Impact Resistance:

Designed to withstand significant pressure and impact, making it an ideal choice for households with children or commercial spaces where heavy items are frequently moved.

Thermal Stability:

Able to handle temperature fluctuations that would cause standard glass to crack. This makes it an excellent tempered glass for outdoor tables, especially in environments exposed to direct sunlight during the day and cooler nighttime air.

Flawless Edges:

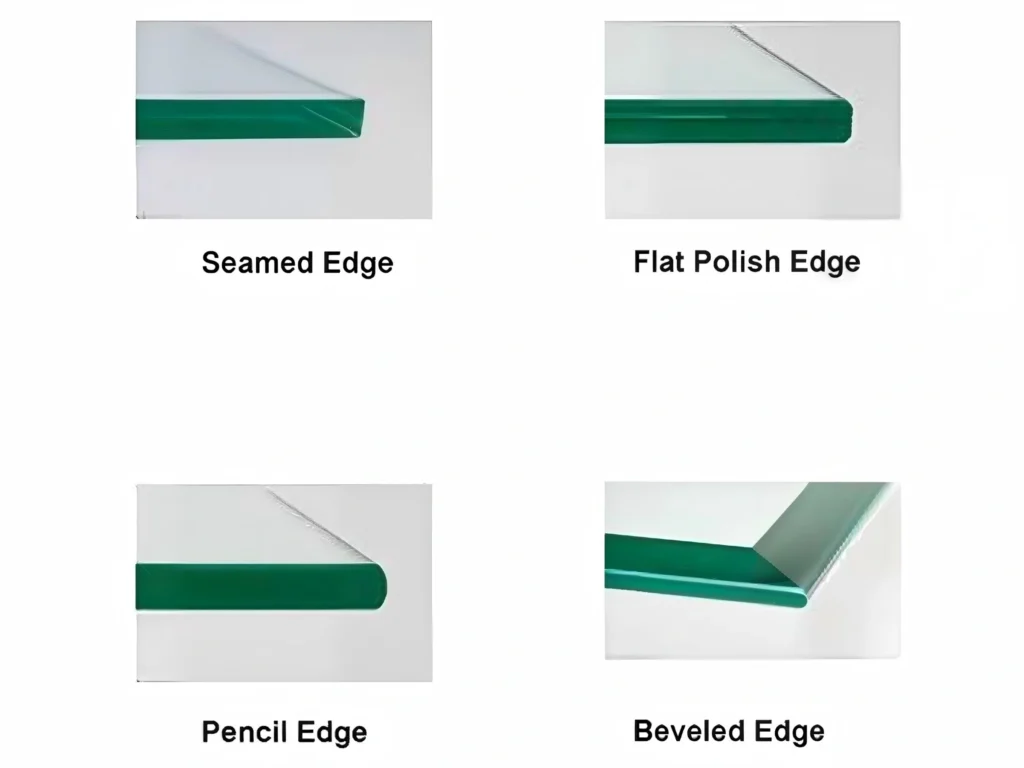

Our glass is precision-polished to achieve smooth, refined edges. Whether you prefer flat-polished, rounded, or elegantly beveled edges, the surface feels silky to the touch and looks visually stunning.

Crystal Clear Transparency:

Made from high-quality float glass, it minimizes the green tint commonly found in lower-grade thick glass, ensuring your tabletop remains a true visual centerpiece.

Customizable Aesthetics:

Beyond clear glass, we offer options such as frosted tempered glass table top, creating a sleek, modern matte look that helps conceal fingerprints while enhancing privacy.

Specification for 10mm Toughened Table Top Glass

For the architects and procurement managers, technical precision is non-negotiable. Below are the standard specifications for our 10mm range.

| Feature | Specification Details |

| Standard Thickness | 10mm (Tolerance: ±0.2mm) |

| Glass Type | Clear, Extra Clear (Low-Iron), Tinted, or Frosted |

| Edge Work | Flat Polished, C-Edge (Pencil), Beveled, Ogee |

| Corner Type | Dubbed corner, Radius corner, Clipped & Polished |

| Max Dimensions | 2140mm x 3300mm, 84×130 (Custom sizes available) |

| Processing Options | Hole drilling, CNC cut-outs, Sandblasting |

| Strength | 4-5x stronger than standard annealed glass |

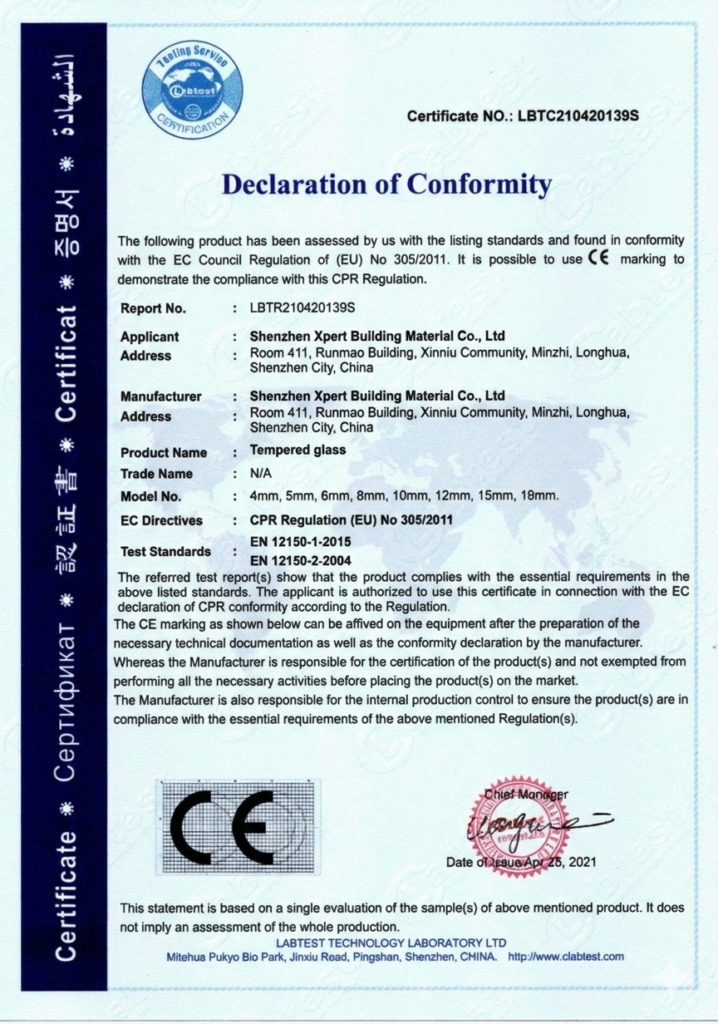

| Fragmentation | Safe small particles upon breakage (EN 12150-1) |

| Heat Resistance | Up to 250°C |

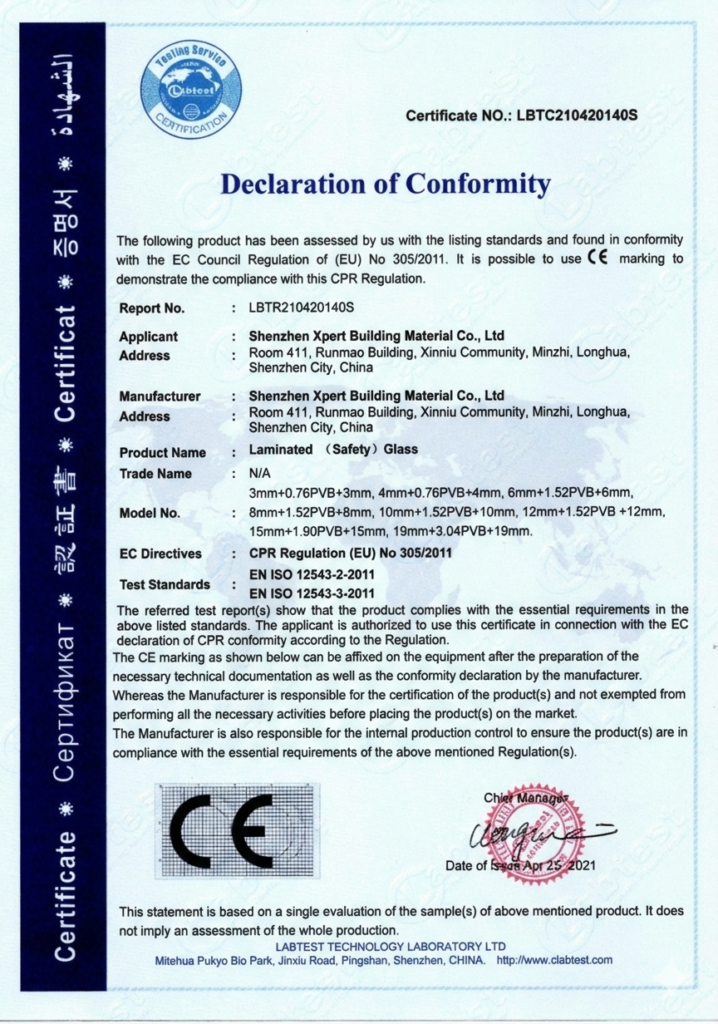

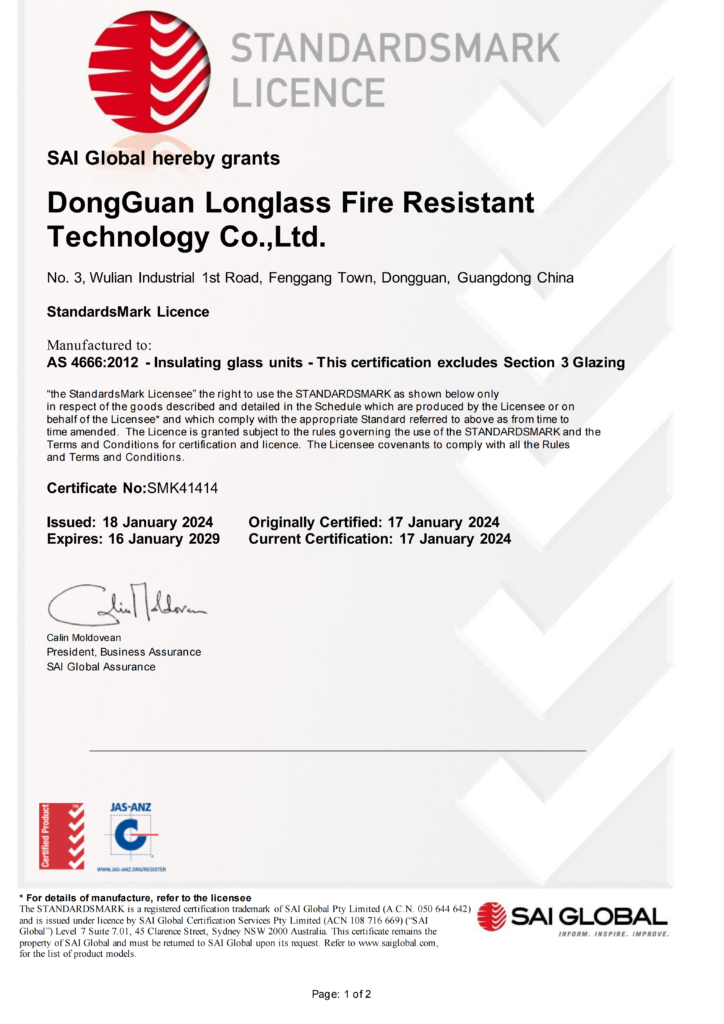

| Compliance | CE, ASTM C1048, AS/NZS 2208:1996 |

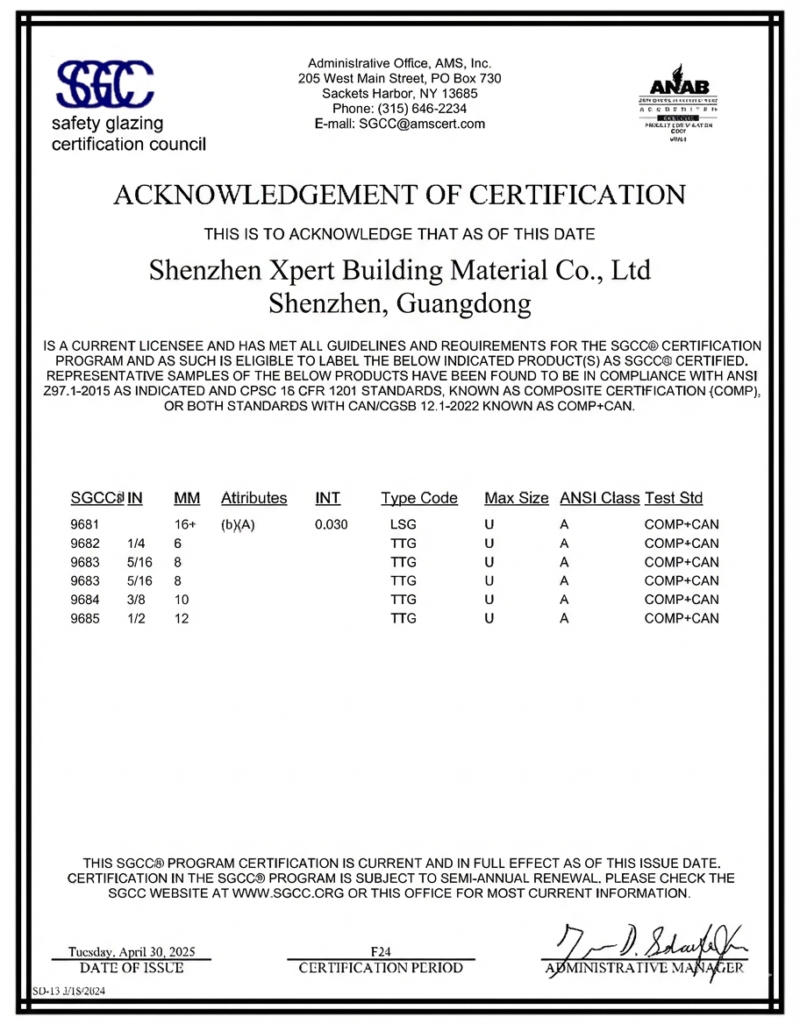

Certification for 10mm Toughened Table Top Glass

Applications for 10mm Toughened Table Top Glass

Versatile Applications Beyond Furniture

The versatility of this material extends far beyond simple furniture—it also serves as a structural element in modern design.

Residential Dining and Coffee Tables

A made tempered glass table can become the centerpiece of any dining space. The 10 mm thickness provides sufficient structural strength to span wider surfaces without sagging, allowing for clean, minimalist table leg designs.

Professional Office Environments

In conference rooms, a 10 mm thick glass tabletop conveys openness and a contemporary aesthetic. It is also exceptionally easy to clean, an essential consideration in modern office management.

Outdoor Furniture

Using tempered glass for outdoor table is an excellent way to protect wooden or rattan furniture from the elements. It prevents water damage and UV fading while providing a flat, durable, and easy-to-clean surface for outdoor dining.

Retail and Showroom Displays

With excellent scratch resistance, 10 mm tempered glass is ideal for high-traffic retail displays. Even after the placement and movement of thousands of items, it maintains its clarity and polished appearance.

Decorative Privacy Solutions

Frosted tempered glass table tops are a popular choice for home offices or side tables. Acid-etched or sandblasted finishes gently diffuse light, creating a warm ambiance while discreetly concealing cables, documents, or other clutter beneath.

Safety Packages Information for 10mm Toughened Table Top Glass

Shipping glass globally is an art form. We treat every sheet of 10mm toughened table top glass as a delicate instrument.

Interleaving: Every sheet is separated by non-adhesive cork pads or specialized paper to prevent friction and “glass rot” during sea transit.

Edge Protection: We use reinforced plastic or cardboard corner protectors to prevent chipping during handling.

Custom Plywood Crates: We do not use “fume-treated” wood that can introduce moisture. We use high-quality, ISPM-15 compliant plywood crates that are built to the specific dimensions of your order.

Security Banding: Crates are steel-banded and fitted with “Tip-N-Tell” or “ShockWatch” sensors upon request to monitor handling throughout the journey.

Vacuum Sealing: For long-distance sea freight, we can offer moisture-proof wrapping to ensure the glass arrives crystal clear.

Investing in 10mm toughened table top glass is an investment in both safety and timeless design. Whether you are looking for a durable tempered glass for outdoor table use or a sophisticated frosted tempered glass table top for a modern office, Xpert Building Material delivers the quality and reliability your project deserves.

We don’t just supply glass; we provide the peace of mind that comes with knowing your furniture is built to last. Let us help you find the perfect specification for your next build.

Contact Us Today for a Custom Quote:

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

FAQs for 10mm Toughened Table Top Glass

Absolutely. While 6mm or 8mm is often used as a “cover” for wooden tables, 10mm is the entry-level thickness for a “standalone” glass top where the glass is supported only by a base or legs. It provides excellent structural rigidity.

No. This is a common misconception. All cutting, drilling, and shaping must happen before the tempering process. If you attempt to drill into a toughened sheet, the entire piece will shatter into small granules.

A ground edge has a frosted appearance and is slightly rough—fine for glass that will be hidden in a frame. A polished edge is buffed until it is as clear and shiny as the surface of the glass, which is essential for any exposed table top.

Frosted glass requires a bit more care than clear glass. Use a lint-free microfiber cloth and a non-ammonia-based glass cleaner. Avoid oily cleaners, as they can leave streaks in the etched surface.

Although tempered glass can withstand temperatures of up to approximately 250°C, we always recommend using heat-resistant mats or coasters.

Even tempered glass can be affected by sudden, localized thermal shock—for example, placing a pot of boiling water directly from the stove onto a cold glass surface—which may introduce stress into the glass.

Standard glass contains a higher level of iron, which gives it a natural green tint.

This green hue becomes especially noticeable when paired with white or light-colored table bases.

Low-iron glass (often referred to as “ultra-clear glass”) eliminates this tint, delivering a perfectly natural, neutral appearance.

Toughened glass is very hard, but not diamond-hard. Fine scratches can sometimes be buffed out using cerium oxide, but deep scratches are permanent. We recommend using felt pads under heavy or abrasive decor.