ANSI Standard 12mm Low Iron Toughened Glass: The Safest & Most Stunning Solution for Modern Spaces

ANSI Standard 12mm Low Iron Toughened Glass: The Safest & Most Stunning Solution for Modern Spaces

Product: ANSI Standard 12mm Low Iron Toughened Glass

Thickness: 12mm, 1/2 Inch

Color: Low iron

Size: Customized, 3300x10000mm

Application: door, railing, fish tank, table top, partition wall, exterior wall, facade, etc.

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 Square Meters

Supply Ability: Over 10000 Square Meter / Day

Country of Origin: China

Lead Time: 10 Days

Payment Term: Bank Wire Transfer

Require more details about the 12mm low iron toughened glass price, let us know anytime! sales@xpertglazing.com or WhatsApp +86 15711964309

Heat Treated Glass

What is 12mm Low Iron Toughened Glass?

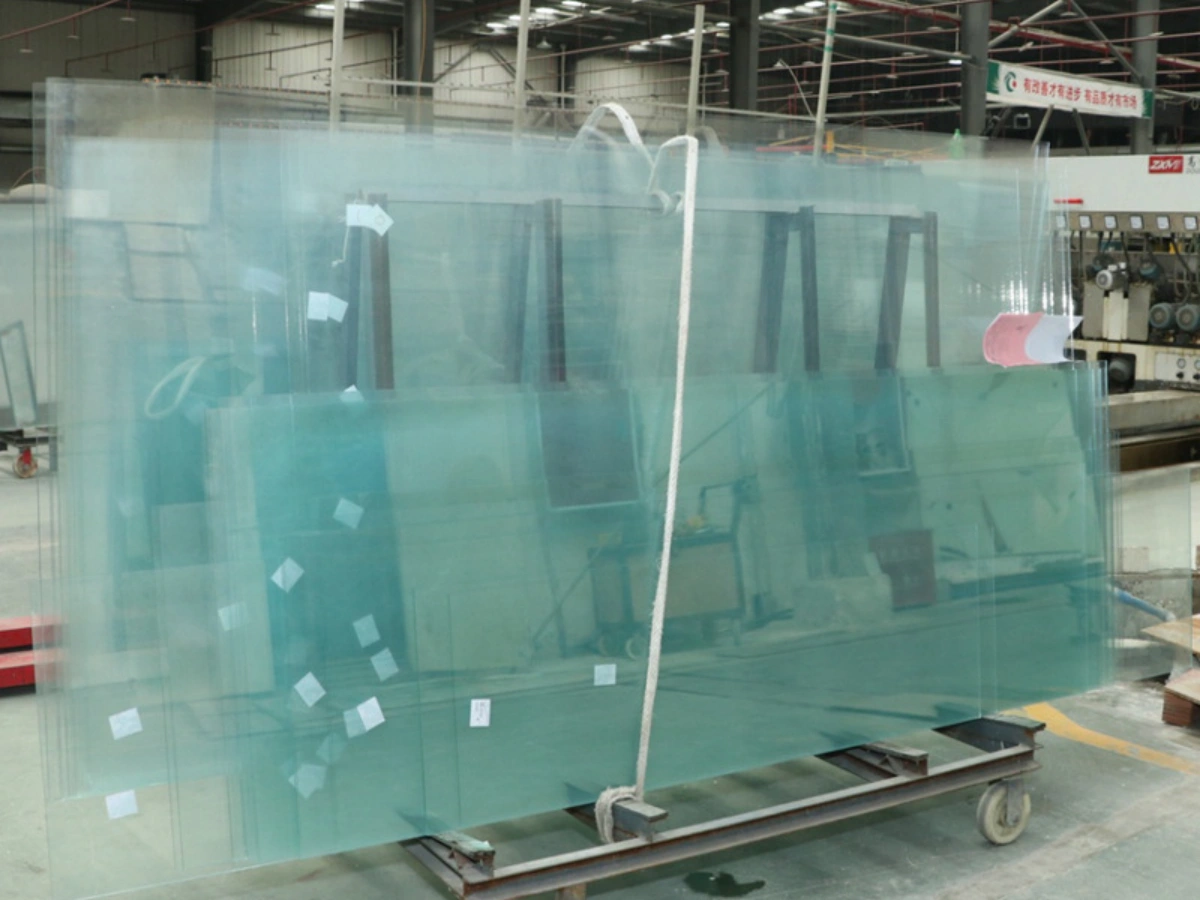

For high-end architectural glass, the “green tint” typical of ordinary glass is often a decisive drawback. 12mm Low iron toughened glass perfectly resolves this issue. By significantly reducing the iron oxide (iron) content during the production process, manufacturers can create glass that is exceptionally clear and color-neutral.

This tempered Starlight glass, approximately 1/2 inch (12 mm) thick, not only delivers a stunning appearance but also offers outstanding structural strength. The “tempering” process involves heating the glass to about 650°C and then rapidly cooling it with high-pressure air jets. This creates internal stresses that make the glass up to five times stronger than standard annealed float glass.

Whether you call it ultra-clear glass, low-iron glass, or 12mm tempered Starlight ultra-clear glass, the end result is the same: a premium building material that maximizes light transmission and presents true-to-life views, making it the gold standard for luxury residences and high-end commercial projects.

Processing Flow for Ultra Clear 6mm Toughened Glass

Why Choose 12mm Low Iron Toughened Glass from Xpert Building Material?

In the fast-paced world of construction and interior design, the quality of your glass is only as good as the reliability of your supplier. Xpert Building Material has built a reputation as a cornerstone in the industry, backed by the trust of global developers and architectural firms.

Rave Reviews from Partners: Our long-term cooperative partners frequently highlight our commitment to precision. We don’t just ship glass; we provide solutions that fit your specific site requirements.

Fast Response & Expert Consultation: Time is money on a job site. Our technical team provides rapid quotes and design feedback, ensuring your project timeline stays on track.

Stable Supply Chain: We have secured deep-rooted relationships with raw material providers. This means even during market fluctuations, we maintain a consistent inventory of 12mm thick heat toughened glass panels.

Rapid Delivery Logistics: With optimized packing and strategic shipping routes, we ensure your ultra-clear glass arrives safely and swiftly, whether you are local or overseas.

Features of 12mm Low Iron Toughened Glass

Why do designers specifically request glass with this thickness and level of clarity? Here are its standout features:

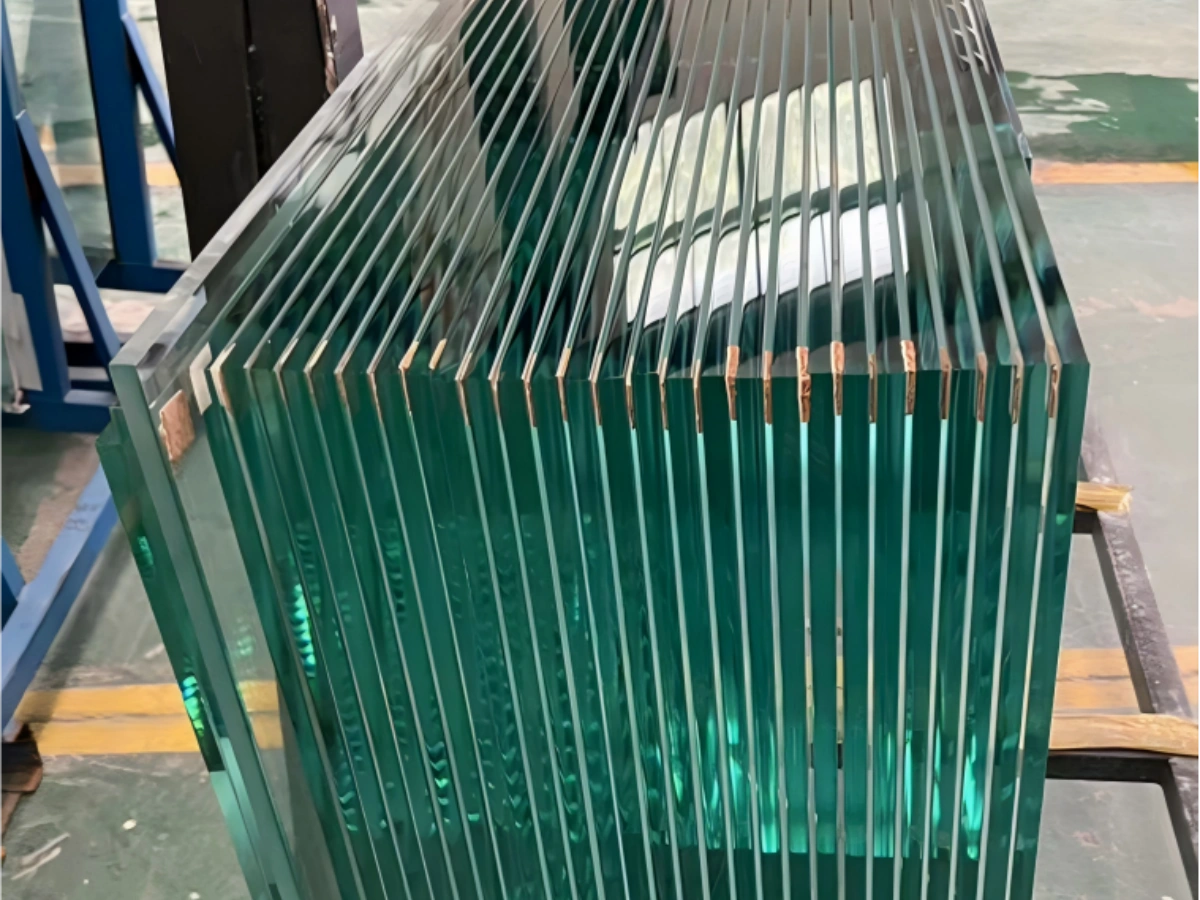

Exceptional optical clarity: 12mm standard toughened glass exhibits a noticeable green edge tint. Low-iron glass remains crystal clear from every angle, which is critical for applications against white walls or in premium display spaces.

High impact resistance: The 12 mm thickness forms a robust barrier. It can withstand strong wind loads and significant physical impacts.

Thermal stability: It resists cracking even under dramatic temperature fluctuations, making it highly suitable for environments with direct sunlight exposure.

Enhanced safety: In the rare event of breakage, the glass fractures into small, blunt-edged granules rather than sharp shards.

Superior light transmission: It allows over 90% of natural light to pass through, reducing the need for artificial lighting and significantly improving occupant comfort and well-being.

Specifications for 12mm Low Iron Toughened Glass

For the architects and engineers who need the hard data, here is a breakdown of the technical specifications for our 12mm low-iron tempered glass product.

| Feature | Technical Specification |

| Glass Type | Low Iron / Ultra-Clear / Starphire Equivalent |

| Thickness | 12mm (Approx. 1/2 Inch) |

| Edge Work | Polished Flat Edge, C-Edge, Beveled Edge |

| Processing Options | Drilled holes, Cut-outs, Heat Soaked, Frosted, Silkscreen Printed |

| Max Size | 3300mm x 12000mm (Jumbo sizes available) |

| Tolerance | ± 0.2mm |

| Surface Quality | Scratch-free, No bubbles, No inclusions |

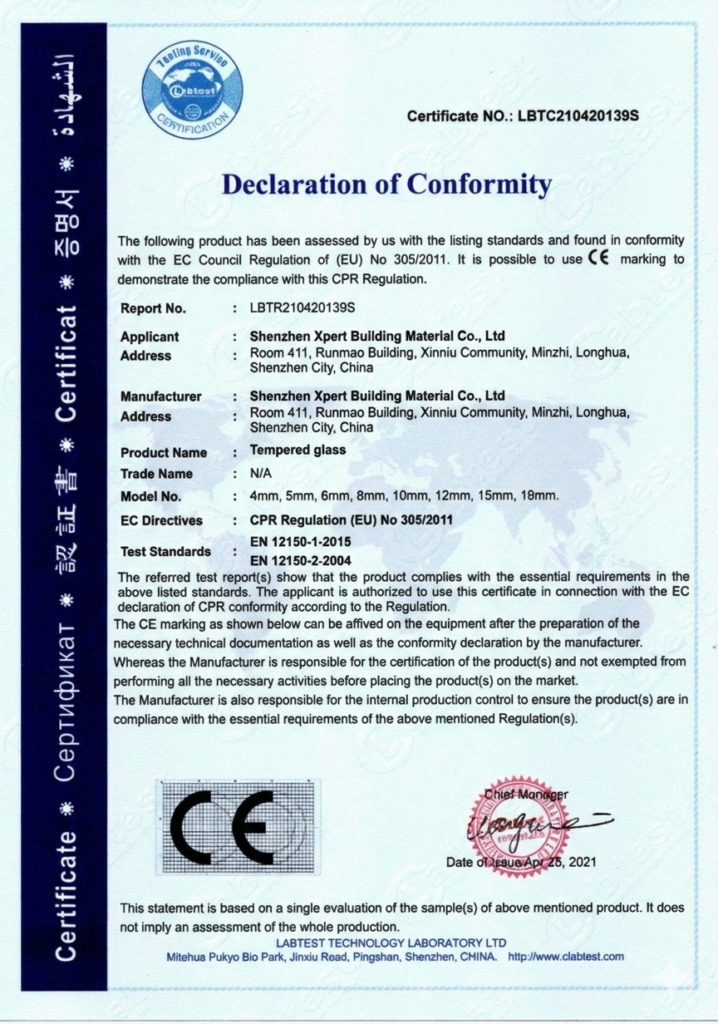

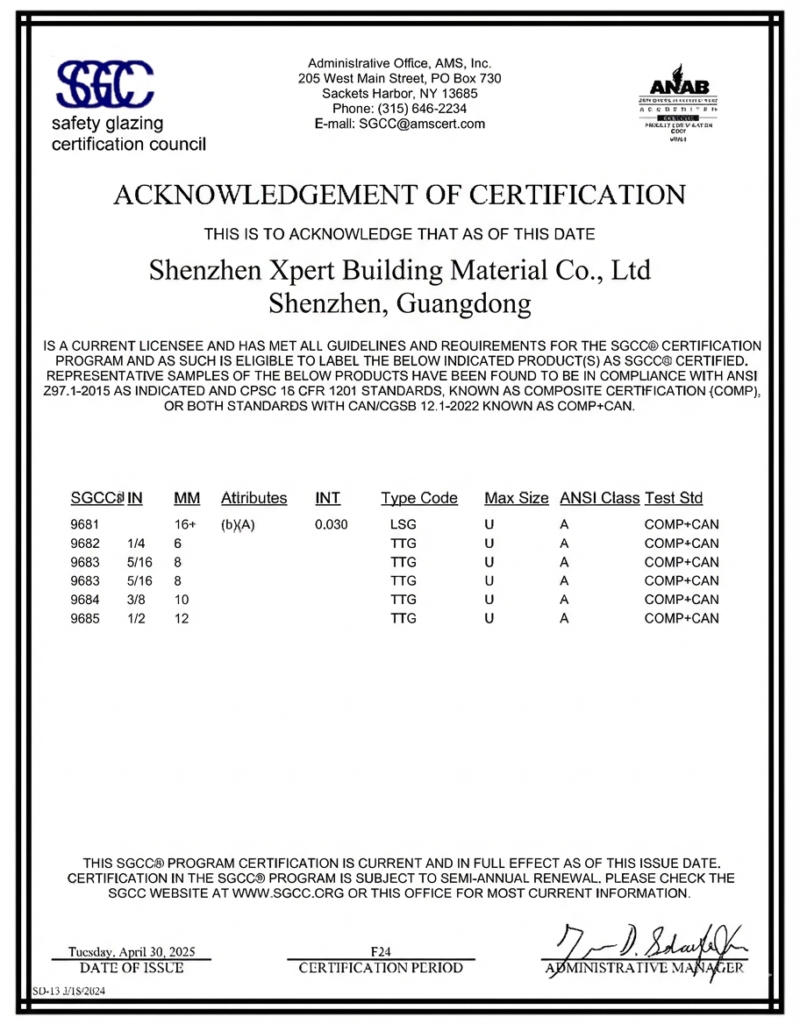

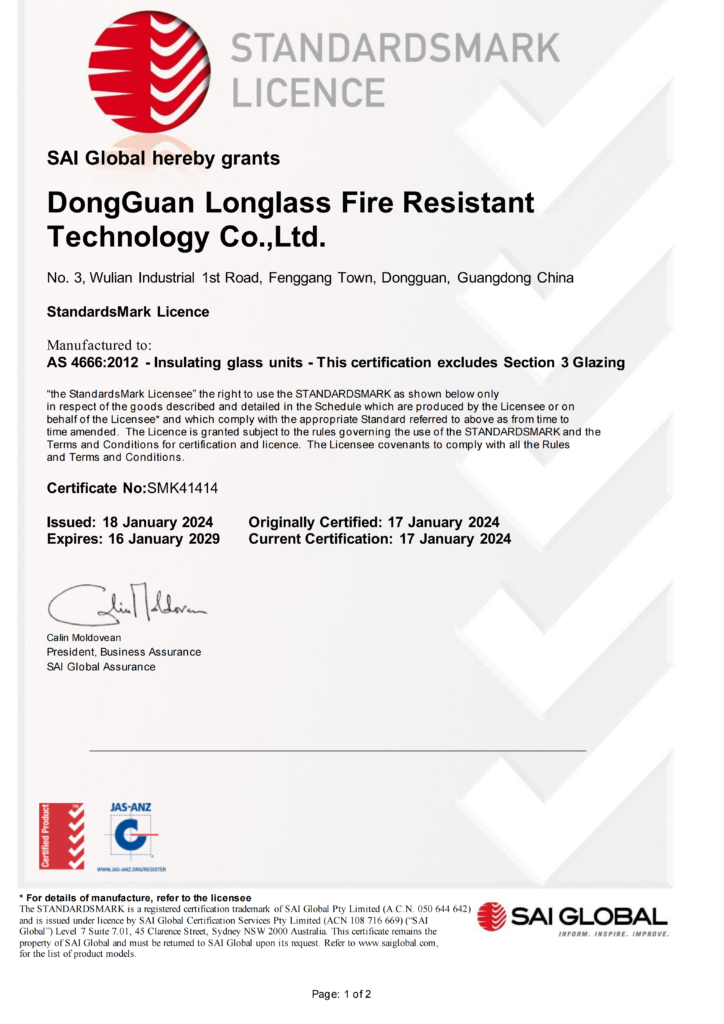

| Compliance | AS/NZS 2208, ASTM C1048, CE EN12150 |

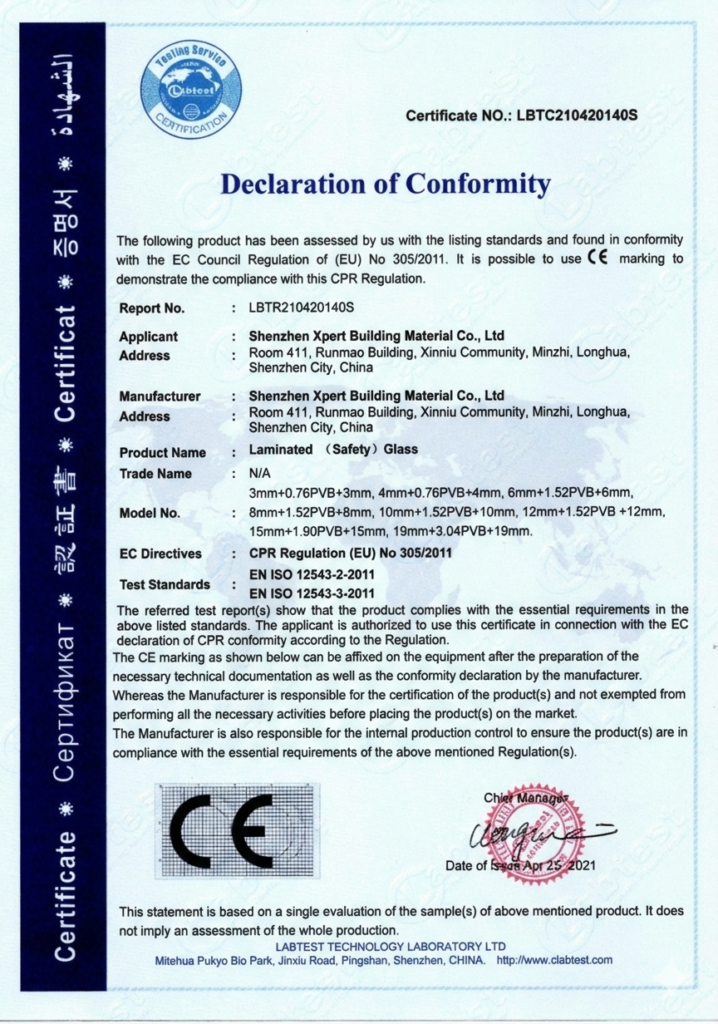

Certification for 12mm Low Iron Toughened Glass

Applications for 12mm Low Iron Toughened Glass

1 2 inch toughened starphire glass is versatile and can be used for partitions or structural elements, with advantages that are hard to overlook. Here are its most common application scenarios:

Office partitions: It creates an open-plan office atmosphere while still providing effective sound insulation. The 12 mm thick toughened glass for partitions ensures the office remains bright and airy, fostering a comfortable and pleasant working environment.

Luxury shower enclosures: 12mm toughened starphire ultra-clear glass delivers a sleek “frameless” look for high-end hotels and residences, combining luxury with exceptional durability.

Glass railings and handrails: Ideal for balconies and staircases, offering unobstructed panoramic views while maintaining safety.

Retail storefronts and display cases: Jewelry stores and luxury boutiques use low-iron glass to ensure customers see the true, undistorted colors of the merchandise.

Glass floors and staircases: When made with laminated glass of this thickness, it provides both safety and stunning aesthetics, making it a perfect walking surface.

These applications highlight why 12mm low-iron tempered glass has become a preferred choice in premium architectural and interior design projects. Let me know if you’d like to continue with more text or adjust the style!

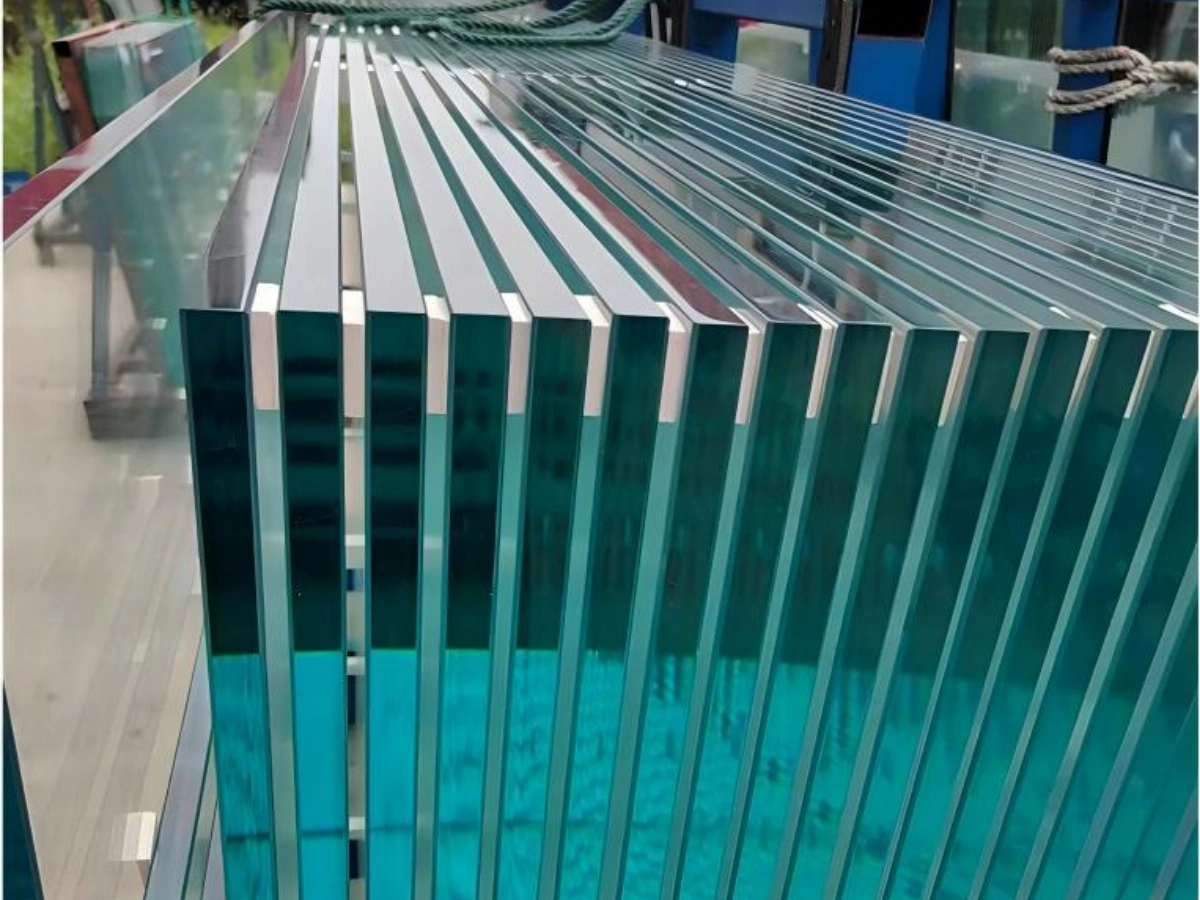

Safety Packages & Logistics Information for 12mm Low Iron Toughened Glass

Shipping glass is a science. At Xpert Building Material, we treat every 12mm thick heat toughened glass panel like a fragile masterpiece.

Interlayer Protection: We use specialized paper or cork pads between every sheet to prevent friction and scratches during transit.

Customized Wooden Crates: Our glass is packed into brand-new, strong, seawater-resistant plywood crates.

Steel Banding: Crates are reinforced with steel bands to ensure they remain rigid during crane or forklift handling.

Desiccant Packs: To prevent “glass clouding” or moisture damage during long sea voyages, we include moisture-absorbing packets within the packaging.

Global Tracking: We provide full documentation and tracking so you know exactly when your materials will arrive at the port or job site.

Whether you are designing a sleek corporate headquarters or a modern residential masterpiece, our 12mm Low Iron Toughened Glass offers the perfect blend of safety and aesthetics. Don’t settle for the green tint of the past—choose the ultra-clear future.

Contact Xpert Building Material Today:

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

Expertise you can see through. Quality you can feel.

FAQs for 12mm Low Iron Toughened Glass

No. All cutting, drilling, and edge polishing must be completed before the toughening process. Attempting to cut it afterward will cause the entire panel to shatter.

Yes, 12mm (1/2 inch) is the industry standard for frameless partitions and glass doors due to its inherent stiffness and weight.

Yes, we can acid-etch or sandblast the surface. Using low iron glass for frosting results in a much whiter, “purer” frosted look compared to the greenish tint of standard frosted glass.

While 12mm glass is a single pane, it can be incorporated into an Insulated Glass Unit (IGU) with Low-E coatings to significantly improve thermal performance.

Depending on the complexity of the fabrication (holes, notches, or shapes), our standard production time is typically 7-15 days, followed by shipping.

The extra 2mm provides significantly more structural rigidity and sound insulation, which is vital for meeting building codes in high-occupancy public spaces.