Wholesale EN12150 Low Iron 8mm Toughened Safety Glass – The Professional Procurement Guide

Wholesale EN12150 Low Iron 8mm Toughened Safety Glass – The Professional Procurement Guide

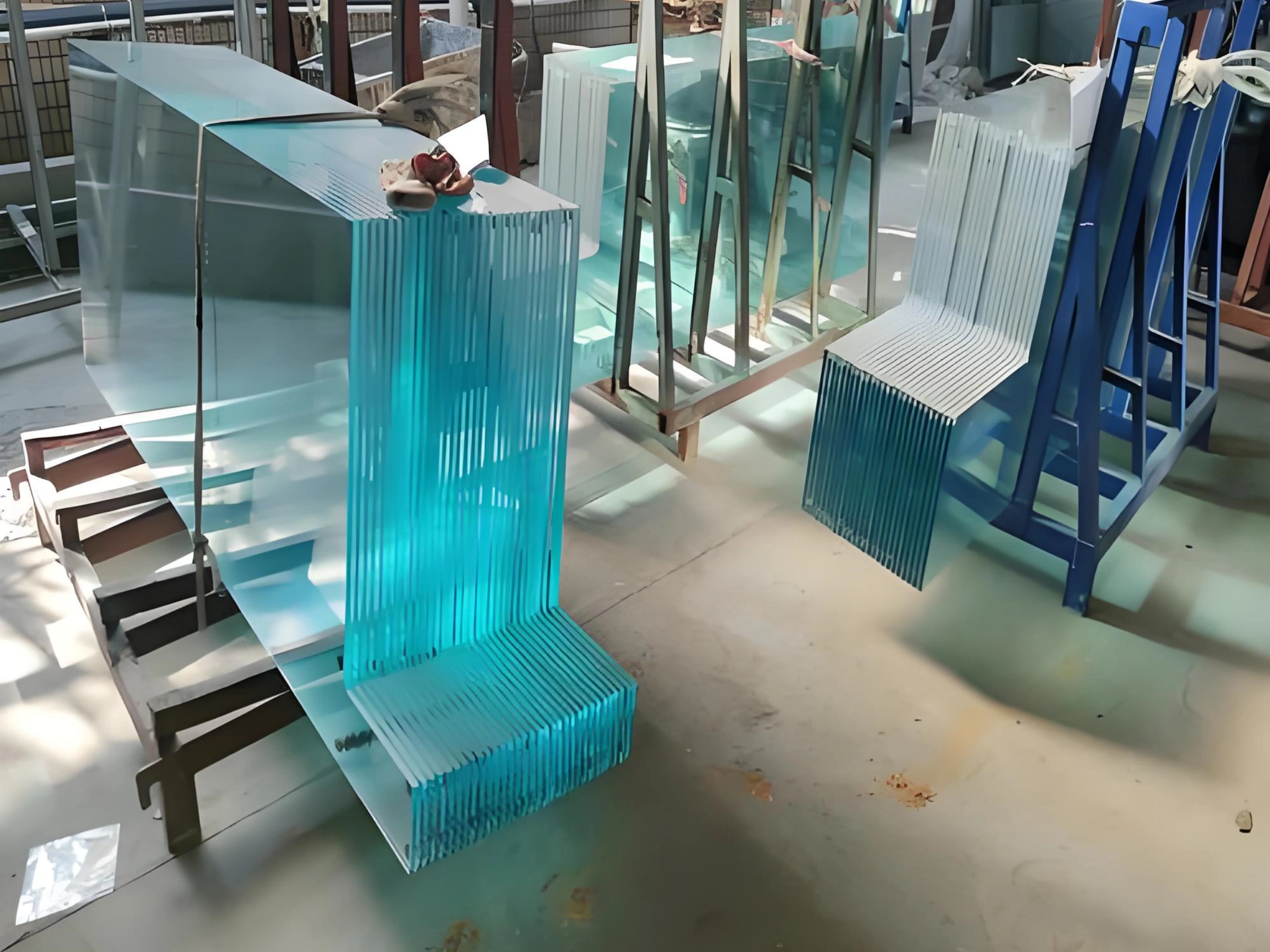

Product: EN12150 Low Iron 8mm Toughened Safety Glass

Thickness: 8mm, 5/16 Inch

Color: Clear, low iron

Size: Customized, 2700x4000mm

Application: door, railing, fish tank, facade, table top, exterior wall, etc.

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 10 Square Meters

Supply Ability: Over 10000 Square Meter / Day

Country of Origin: China

Lead Time: 10 Days

Payment Term: Bank Wire Transfer

Require more details about Low Iron 8mm toughened glass price, let us know anytime! sales@xpertglazing.com or WhatsApp +86 15711964309

Heat Treated Glass

In the high-stakes world of commercial construction and architectural glazing, the difference between a project’s success and a costly delay often hinges on material reliability. For procurement officers and glazing contractors, Low Iron 8mm Toughened Safety Glass represents more than just a clear view—it is a critical structural component that must meet rigorous safety standards while maintaining optical perfection.

At Xpert Building Material, we specialize in high-volume supply and bespoke fabrication of Ultra Clear 8mm toughened glass. We understand the B2B landscape: you need stable pricing, fast response times, and a supply chain that doesn’t buckle under the pressure of large-scale project timelines.

What is Low Iron 8mm Toughened Safety Glass?

From a technical standpoint, Low Iron 8mm Toughened Safety Glass is a premium float glass where the iron oxide content has been reduced to less than 0.01%.

Optical Neutrality for Professionals

Standard 8mm toughened glass carries a significant green hue due to iron contaminants. In commercial applications—such as storefronts or high-end office partitions—this tint can distort the color of interior branding and reduce light transmission. Low iron glass, frequently specified as 8mm starphire tempered glass, offers a light transmittance of over 91%, ensuring the “true color” of the environment is preserved.

Engineering the Safety Profile

The “Toughened” designation refers to the thermal tempering process. By heating the glass to roughly 620°C and rapidly cooling it, we introduce permanent surface compression. This makes the glass five times more resistant to mechanical and thermal stress than annealed glass. In the event of a catastrophic failure, it breaks into small, relatively harmless blunt fragments, meeting global safety regulations for public spaces.

Processing Flow for Low Iron 8mm Toughened Safety Glass

Why Partner with Xpert BM for Low Iron 8mm Toughened Safety Glass Supply?

Choosing a glass partner is a strategic business decision. Our cooperated partners—including international construction firms and furniture manufacturers—rely on us for four specific reasons:

Fast Response & Technical Consultation

We don’t just take orders; we solve problems. Whether you are dealing with complex shop drawings or need a quick estimate for a tender, our team provides a fast response. We understand that in B2B, a delay in communication is a delay in the project.

Stable Supply Chain

Market volatility can ruin a project’s budget. Xpert Building Material maintains long-standing relationships with raw material suppliers, allowing us to offer a stable supply chain. We mitigate the risks of “out of stock” scenarios that plague smaller distributors, ensuring your Low Iron 8mm toughened glass price remains competitive throughout the contract duration.

Fast Delivery and Logistics Expertise

We manage the entire logistics chain. From our factory to your warehouse or directly to the job site, we prioritize fast delivery. Our logistics team is experienced in handling customs documentation, duty calculations, and international shipping routes to minimize transit times.

Features of Low Iron 8mm Toughened Safety Glass

Superior Clarity: Critical for retail clusters where product display accuracy drives sales.

Consistent Thickness: Strict ±0.2mm tolerance ensures compatibility with standard U-channels and hardware.

Enhanced Edge Finishing: Our 8mm low Iron bespoke toughened glass features high-quality polished edges, essential for frameless glass-to-glass joints.

Thermal Performance: Resists temperature differentials, making it suitable for exterior facades and areas near high-heat HVAC outlets.

Compliance Ready: Every batch is tested to meet international standards (CE, AS/NZS, SGCC).

Specification for Low Iron 8mm Toughened Safety Glass

| Parameter | Specification |

| Glass Substrate | Low Iron (Ultra-Clear) Float |

| Mechanical Strength | 120-150 N/mm² (Toughened) |

| Light Transmittance | ≥ 91% |

| Thickness Tolerance | ± 0.2 mm |

| Max Process Size | 2700mm x 4000mm (Custom Jumbo sizes available) |

| Standard Compliance | EN 12150, ANSI Z97.1, AS/NZS 2208:1996 |

| Edge Finish | Flat Polished, Bevelled, or Mitred (Accurate to 0.5mm) |

| Thermal Shock Resistance | 200°C – 250°C |

Applications for Low Iron 8mm Toughened Safety Glass

This thickness is the versatile “workhorse” of the commercial sector.

Office Partitions: Create open, collaborative environments without the green tint of standard glass.

Retail Storefronts: Showcase high-end merchandise in its true light using 8mm starphire tempered glass.

Hospitality & Hotels: Used extensively for frameless shower doors and premium glass furniture in guest rooms.

Public Infrastructure: Ideal for glass balustrades in malls and airports where safety and visibility are equally prioritized.

Bespoke Splashbacks: Favored by interior designers for back-painted glass projects to ensure white paint remains pure white.

Safety Packages for Low Iron 8mm Toughened Safety Glass

Shipping glass across the globe requires precision packaging to prevent breakage or surface damage. At Xpert Building Material, we use:

High-Strength Plywood Crates: Custom-built for every order, eliminating the need for fumigation in many regions.

Moisture-Proof Protection: We use specialized powders or cork pads between each sheet to prevent scratches and chemical staining during transit.

Steel Banding: All crates are reinforced with steel straps to ensure stability during sea or air transport.

Secure Your Supply Chain with Xpert

Join our network of professional partners who rely on the clarity and strength of our Ultra Clear 8mm toughened glass. Let us help you deliver your next project on time and under budget.

Contact Our Sales Desk:

Email: sales@xpertglazing.com

WhatsApp: +86 15711964309

FAQs for Low Iron 8mm Toughened Safety Glass

While we accommodate 8mm low Iron bespoke toughened glass for smaller high-end projects, our B2B pricing is most efficient for full-crate or container-load volumes. Contact us for a tiered pricing sheet.

8mm is the “sweet spot” for many applications. It is significantly stronger and more rigid than 6mm (which is often used for simple windows), but it is lighter and more cost-effective than 10mm or 12mm glass, which is usually reserved for heavy structural balustrades.

No. This is a critical point for project planning. Once glass has been toughened, any attempt to cut, drill, or notch it will cause the entire pane to shatter. All 8mm low Iron bespoke toughened glass must be cut to size and drilled before the tempering process.

The price is influenced by the current cost of raw silica, the complexity of the “bespoke” elements (like CNC holes or special edge polishing), the volume of the order, and shipping costs. However, Xpert works to keep pricing stable through our supply chain management.

Generally, no. For glass flooring or stairs, you typically require laminated toughened glass, often involving multiple layers of 10mm or 12mm glass. 8mm is better suited for vertical applications like partitions, doors, or splashbacks. If use 8+8mm or 8+8+8mm thickness can be used for glass floor.

Low iron glass is maintained just like regular glass. Use a non-abrasive glass cleaner and a microfiber cloth. Because it is so clear, fingerprints may be slightly more visible than on tinted glass, so regular wiping is recommended in high-traffic areas.

The easiest way is to look at the edge of the glass. Standard glass will have a dark, swampy green edge. Low iron glass will have a very light, almost white or pale blue-green edge.

Heat-soak testing is an optional process we offer. It involves heating the glass for several hours to trigger any potential nickel-sulfide inclusions, further reducing the (already tiny) risk of spontaneous breakage.

It is scratch-resistant, but not scratch-proof. Low iron glass is slightly softer than standard glass due to its purity. Avoid using abrasive cleaners or metal scrapers; a microfiber cloth and vinegar-based solution are best.