Guangdong Super Quality 21.52 mm Tempered Glass Laminate Supplier, Tempered-Laminated Glass 1010.4 Good Price

Guangdong Super Quality 21.52 mm Tempered Glass Laminate Supplier, Tempered-Laminated Glass 1010.4 Good Price

Product: 21.52 mm Tempered Glass Laminate Supplier

Thickness: 10+10mm glass, 21.14mm, 21.52mm, 22.28mm, 27/32 inch

Color: Clear, low iron, or PVB color

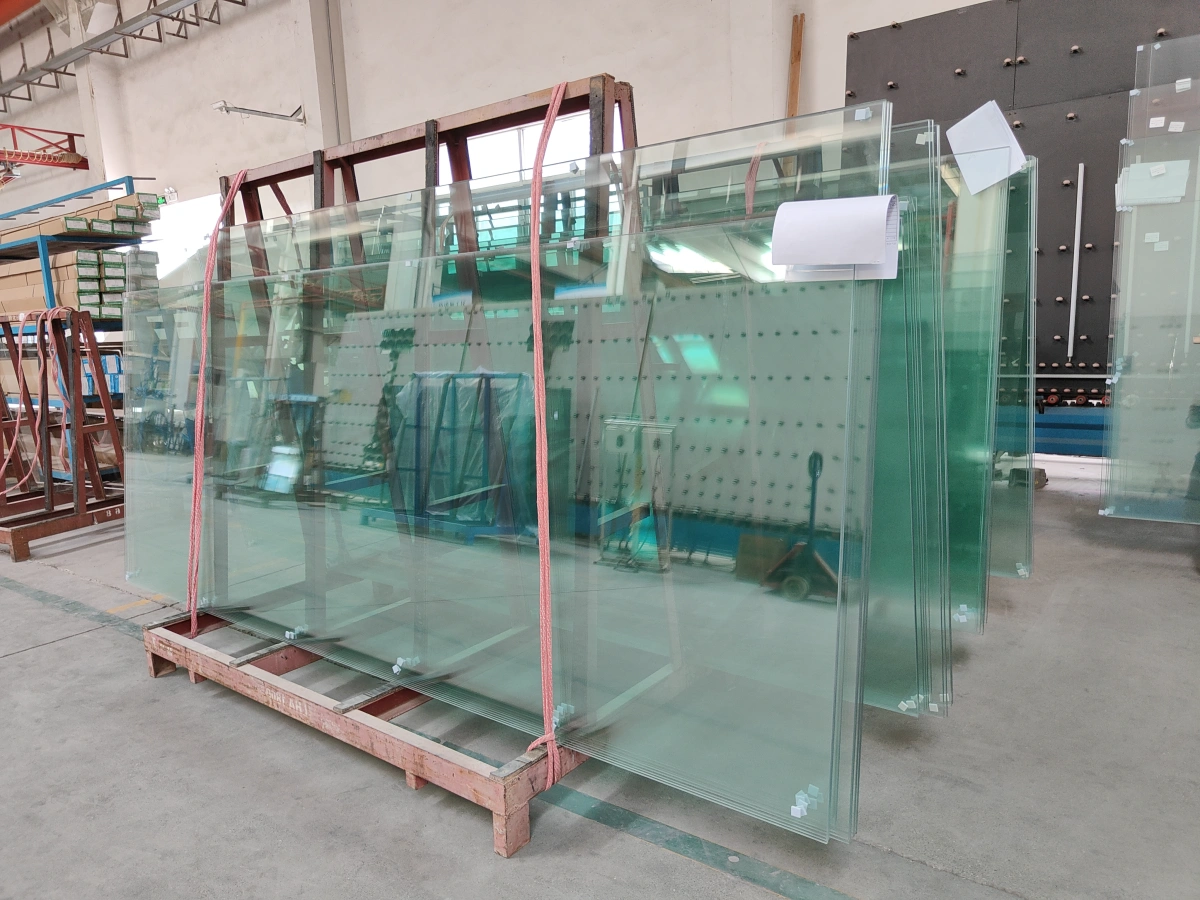

Size: Customized size, less than 3300x8000mm

Application: Railing, window, door, partition, exterior wall.

Sample: Available, 300x300mm standard size

Delivery Term: EXW, FOB, CFR, CIF, DDU, DDP, DAP

Minimum Order Quantity: 20m2

Supply Ability: Over 5000 Square Meter / Day

Country of Origin: China

Lead Time: 15-20 Days

Payment Term: Bank Wire Transfer

Feel free to contact us to get more information for 664 laminated glass, call – +86 15711964309 (WhatsApp), or email to sales@xpertglazing.com

Laminated Safety Glass

What is 21.52 mm Tempered Glass Laminate Supplier?

As a 21.52 mm tempered glass laminate supplier (1010.4) is engineered to deliver the highest level of safety, strength, and performance for demanding architectural projects.

Manufactured in Guangdong, China’s glass industry hub, we combine advanced tempering technology with laminated glass PVB interlayers, ensuring superior resistance against impact, shattering, and environmental stress.

This super-quality laminated glass is trusted by builders, contractors, and designers worldwide for its durability, clarity, and versatility—perfect for projects that demand both elegance and safety.

Why Choose Our 21.52mm Laminated Glass?

Low self-explosion rate: We use glass from industry-leading companies like XYG and CSG to ensure that the problem of tempered glass spontaneously exploding is solved at the source.

Maximum Safety: Even if broken, the glass fragments adhere to the interlayer, preventing injury.

Superior Soundproofing: Significantly reduces external noise (STC rating improvement).

99% UV Blocking: Protects interior furnishings from fading.

Precision Edging: Flat polished edges, dubbed corners, or CNC hole drilling available for easy installation.

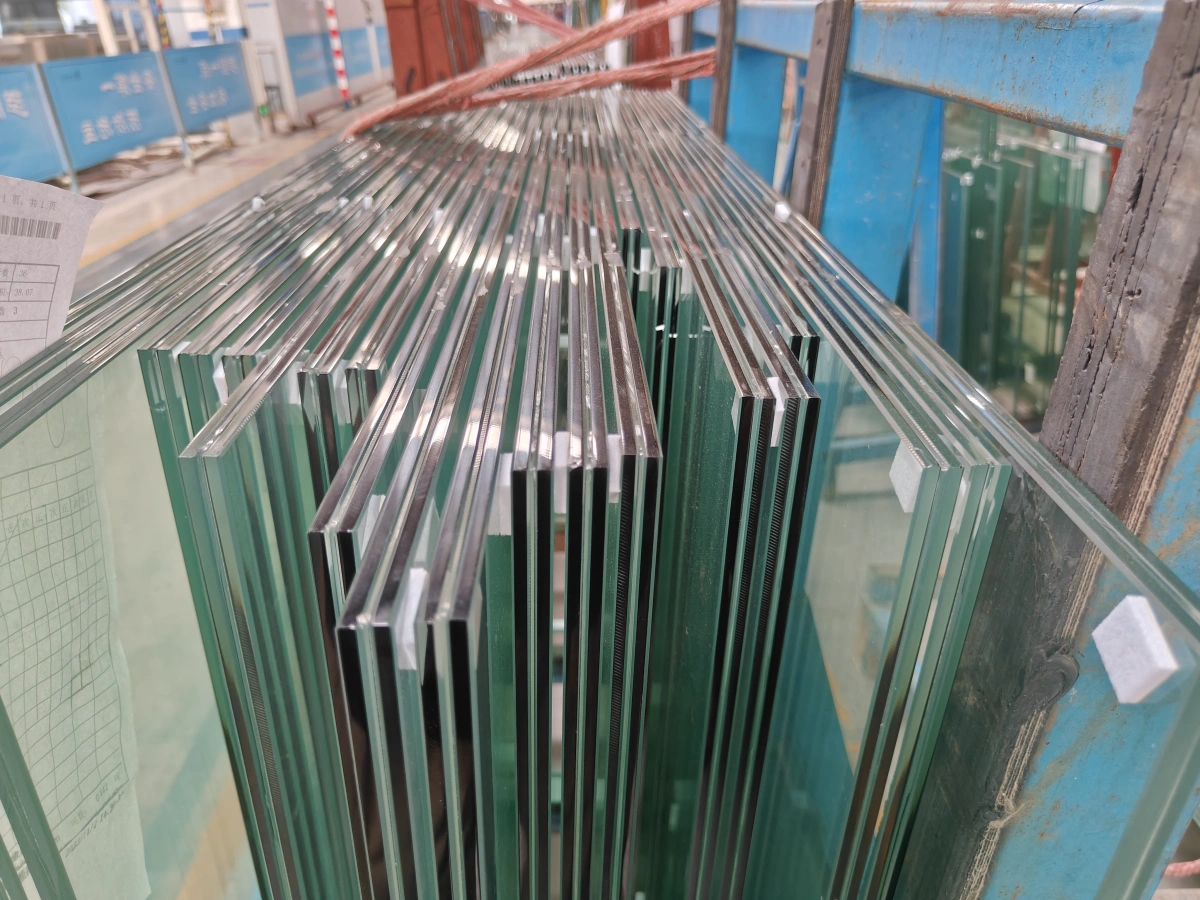

Process Details for Clear Tempered-Laminated Glass 1010.4

Features for 21.52mm Clear Laminated Tempered Custom Size Glass Panel

Extra Strong Safety Protection – Two layers of 10mm tempered glass bonded with 1.52mm PVB interlayer prevent breakage and keep fragments together.

Acoustic Insulation – Significantly reduces noise transmission, ideal for urban environments.

High Transparency – Maintains natural light flow while ensuring protection.

UV Resistance – Blocks 99% of harmful UV rays, protecting interiors and furniture.

Weather & Impact Resistance – Withstands wind pressure, storms, and external force.

Customizable – Available in different sizes less than 3300x8000mm, colors, and edge finishes.

Specification of 21.52 mm Tempered Glass Laminate Supplier

| Item | Specification |

|---|---|

| Product Name | 21.52mm Tempered Laminated Safety Glass |

| Model | 10104 verbund glass |

| Glass Structure | 10mm tempered safety glass + 10mm tempered safety glass+ 1.52mm PVB/SGP or 2.28mm PVB/SGP |

| Thickness | 21.52mm, 20.76mm, 22.28mm |

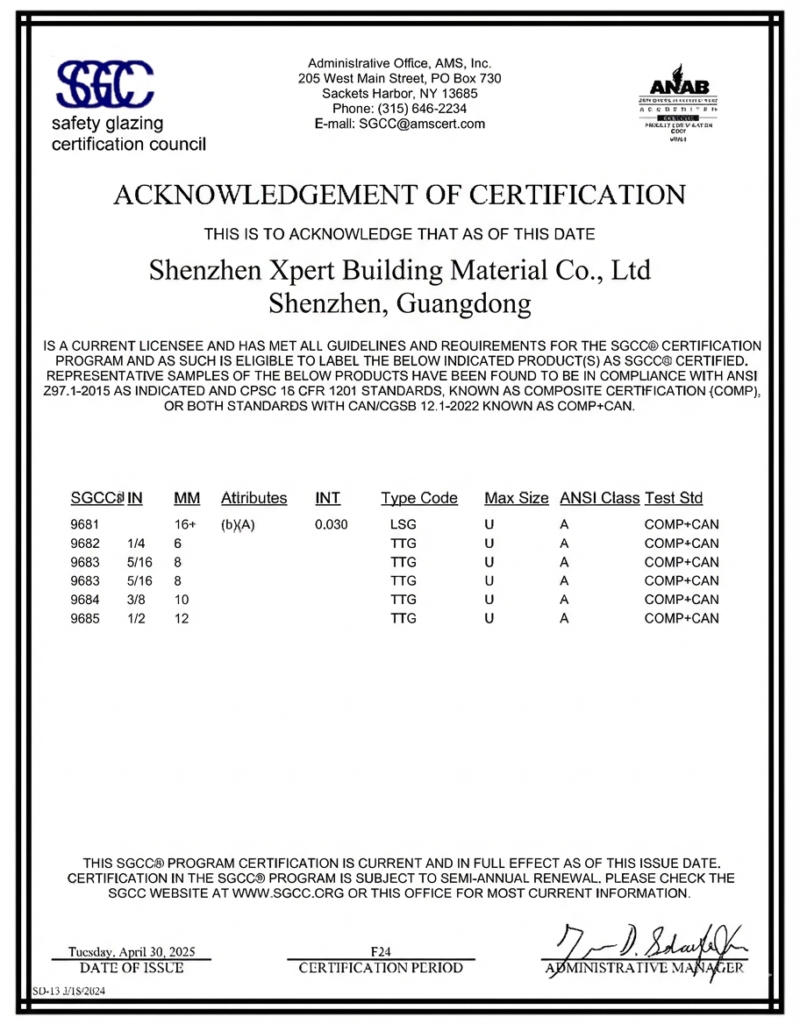

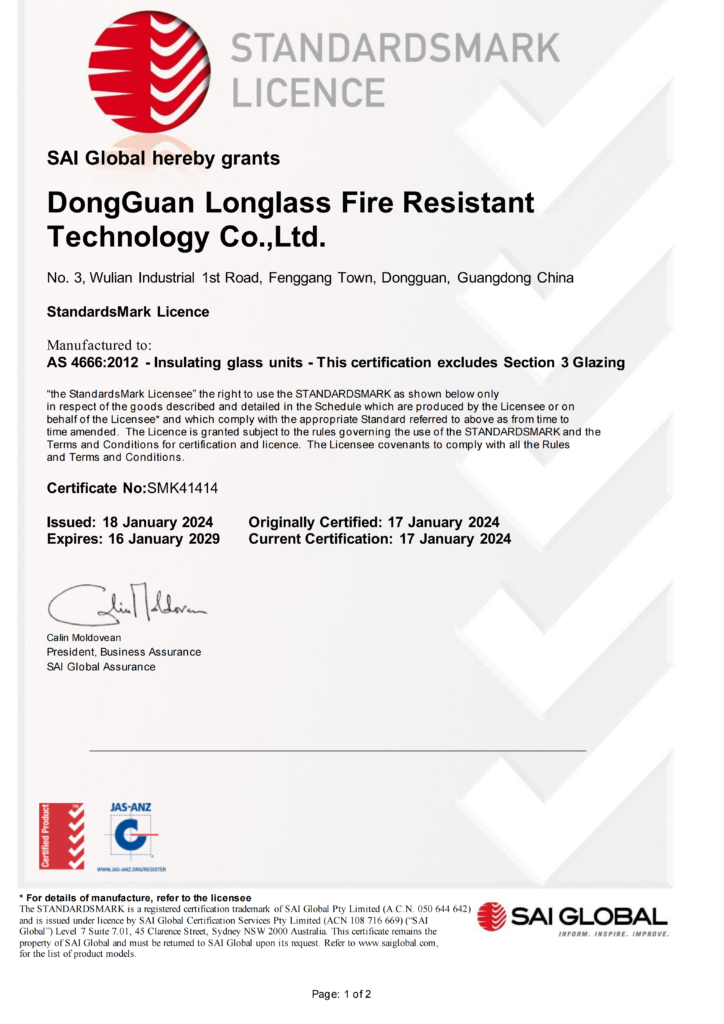

| Standard | EN14449, EN12600, EN12543, SGCC, ISO Certified |

| Interlayer | Clear / Low iron/ Color PVB |

| Max Size | 3300mm x 8000mm (custom available) |

| Transparency | ≥ 88% |

| Acoustic Performance | 35–40 dB reduction |

| UV Blocking | ≥ 99% |

| Edge Finish | Flat polished / beveled / customized |

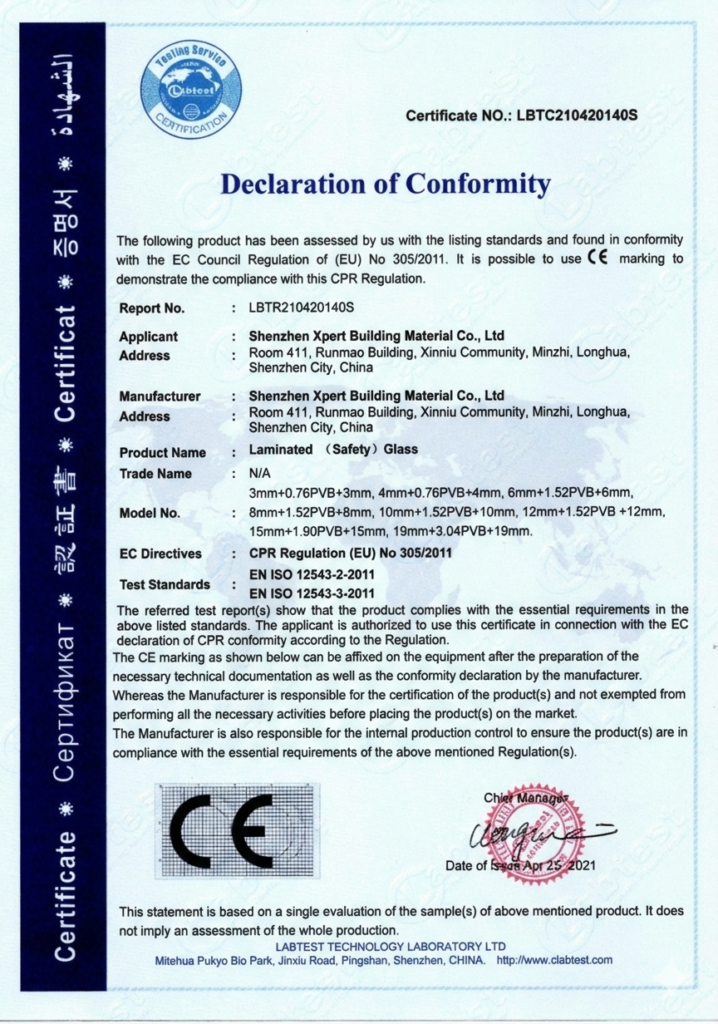

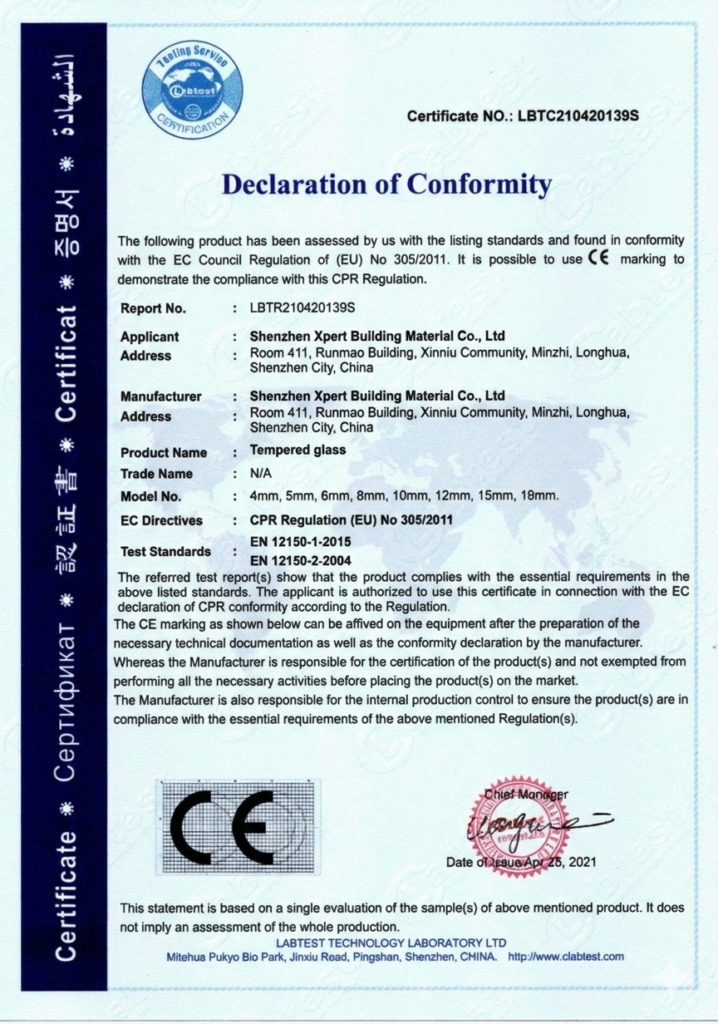

Certification for 10104 Harden Laminated Glass

Application for 10104 Harden Laminated Glass

The 21.52mm Tempered Laminated Glass (1010.4) is ideal for:

- Building Facades & Curtain Walls – Strong & elegant exterior solutions.

- Doors & Windows – Maximum security and clarity.

- Interior Partitions & Skylights – Safe and stylish design choice.

- Balustrades, Railings & Canopies – Extra strength for safety-critical areas.

- Marine & Transportation Use – Ships, trains, and special vehicles.

How Many Different Types with 20mm Thick Clear PVB Safety Tempered Toughened Laminated Glass?

We provide various laminated glass options to meet different design needs:

🔹 Clear Tempered-Laminated Glass 1010.4 – For high transparency projects.

🔹 Tinted 20mm thick clear PVB safety tempered toughened laminated glass – Grey, Bronze, Blue, Green for aesthetics & solar control.

🔹 Frosted / Acid-Etched 21.52mm Clear Laminated Tempered Custom Size Glass Panel – For privacy applications.

🔹 Low-E 21.52 mm Tempered Glass Laminate Supplier – For thermal insulation and energy efficiency.

🔹 Customized Shapes & Sizes – Tailored for specific project requirements.

Packing Information for 10104 Verbund Glass

✅ Each 21.5mm toughened laminated glass cut to size sheet separated by PE film or cork pads.

✅ Wrapped with moisture-proof paper to prevent damage.

✅ Loaded in strong seaworthy wooden crates.

✅ Steel belt reinforcement for safe transportation.

✅ Customized packaging available upon request.

Looking for a reliable laminated glass supplier in Guangdong, China?

👉 We provide factory-direct prices, bulk supply, and OEM services.

With superior quality, competitive pricing, and fast delivery, our products are the best choice for your next project.

📩 [Contact Us Now for a Free Quote!]

FAQs for Order 21.52 mm Tempered Glass Laminate Supplier

It depends on the application:

PVB (Polyvinyl Butyral): Best for standard soundproofing, UV protection, and common safety railings. It is cost-effective and widely used.

SGP (SentryGlas Plus): Ideal for structural glass like glass floors, hurricane-resistant windows, or frameless balustrades. SGP is 5 times stronger and 100 times stiffer than PVB, remaining upright even if both glass panes break.

Yes. 21.52mm is a standard thickness for glass treads and walkable glass surfaces. However, we recommend using a triple-laminated or SGP-laminated option for public commercial areas with high foot traffic to meet local building codes.

Our products are manufactured under strict quality control and comply with international standards including:

Europe: EN 12150 & EN 14449

USA: ASTM C1048 & SGCC (ANSI Z97.1)

Australia/NZ: AS/NZS 2208:1996

Global: ISO 9001

The shipping cost depends on the destination, product type, and shipping method (air, sea, or express).

For large or heavy items like glass, window, door, curtain wall, sea freight is usually the most cost-effective option. While international shipping can be a significant part of the total cost, we always work to find the most economical and efficient solution for our customers and can provide a detailed quotation for your reference.

Absolutely. We provide high-precision CNC cutting, hole drilling, and edge work (Flat polish, C-edge, or mitered edge). Since the glass is tempered, all fabrication must be completed before the tempering process. We require CAD drawings for precise hole positioning.

Please note: As glass is inherently fragile, there is always a risk of breakage during transportation. Even for tempered glass, despite our use of high-quality raw glass from XYG, CSG, and PPG, and processing with advanced tempering furnaces from NorthGlass and LandGlass, there is still an approximate 0.2% risk of spontaneous breakage. If any damage occurs, we will do our best to assist you in minimizing the loss.

Generally, our production lead time is 15–20 days after order confirmation and drawing approval. This may vary slightly depending on the complexity of the processing (e.g., custom shapes or special coatings).