Congratulations to One of Xpert BM’s partner on completing a digital-printed glass project!

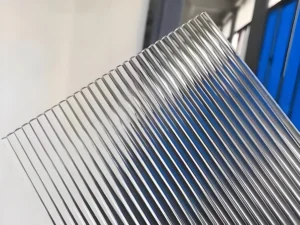

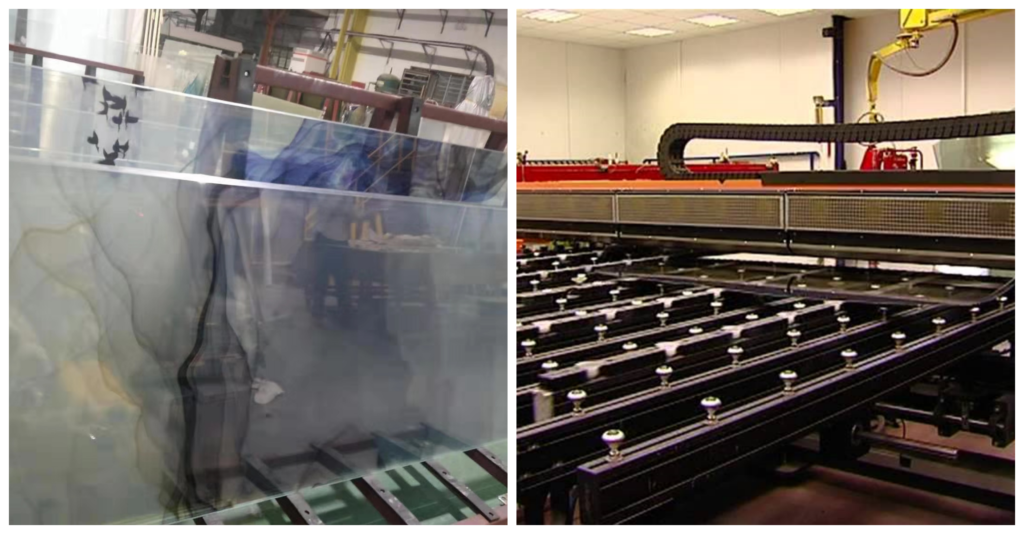

Digital printing on glass using high-performance clarity printers, with fully customized patterns. Each panel is made of ultra-clear tempered laminated glass, 10+10mm thick, and all fittings are from the Kinlong brand to ensure the overall stability of the façade structure.

Why Choose Digital Printed Laminated Sheets Glass for Facade Project?

When you’re designing a building façade, you’re balancing looks, performance, and longevity. Digital printed laminated glass checks all three boxes in ways other materials can’t.

- Storytelling Through the Façade

Unlike plain or tinted glass, digitally printed laminated glass lets the building itself become a canvas. You can translate branding, cultural elements, or abstract patterns directly onto the façade without relying on stickers or cladding that fades over time.

- Built-In Safety and Strength

Because it’s laminated, the glass doesn’t shatter dangerously—it holds together. That makes it safer in high-traffic zones and more resilient against impacts, storms, or accidental breakage. It’s not just about looks; it’s about peace of mind.

- Fade-Free Expression

The digital print is embedded in the glass, not just on the surface. That means no peeling, no fading, no awkward touch-ups. Years down the line, the design will still look as sharp as day one, even under intense sun.

- Comfort Without Compromise

Designs aren’t just decorative—they can serve as functional shading. By controlling transparency and density of patterns, architects can cut glare and heat while still letting natural light flood the interiors. That saves energy and makes interiors more comfortable.

- Quiet and Calm Inside

Urban noise is a growing issue. Laminated glass has natural sound-dampening properties, meaning busy streets outside don’t disturb the experience inside.

- A Long-Term Investment

Instead of cladding or paints that need replacement, laminated printed glass is a one-time investment that lasts decades. It aligns with sustainable design goals by reducing maintenance and waste.

The Challenges for Digital print glass with High-Definition.

- Resolution vs. Viewing Distance

A photo may look perfect on a computer screen, but digital print glass has limits.

Printing resolution is typically 360–1440 dpi, but when spread across a large façade panel, fine details can get pixelated.

For façades, people usually view from a distance, so ultra-fine detail may not translate as expected.

- Color Accuracy & Transparency

Glass is transparent, so colors must be adjusted to ensure they remain vivid after light passes through.

Light behind the digital print glass can wash out details, especially in high-contrast or dark photos.

Achieving photo-realistic gradients without banding (visible steps in color transitions) is technically challenging.

- Layering & Laminating

In digital in-glass printing, the print is applied to an interlayer or directly onto glass, then sealed between sheets.

Aligning multiple panels so the photo remains seamless across the façade is a precision task. Even slight shifts during lamination can distort the image.

- UV Stability & Longevity

High-definition digital in-glass printing photos have subtle color ranges. Maintaining that over 10–20 years of UV exposure requires high-quality ceramic inks or UV-resistant interlayers.

Low-grade inks fade or shift color (e.g., whites turning yellow, blacks turning gray).

- Cost & Production Time

Photo printing requires specialized machines (ceramic digital printers or UV printers) and more ink passes for detail.

This makes it slower and costlier than printing simple patterns or graphics.

- Scaling Large Images

A façade-sized photo may span dozens of panels. Ensuring perfect image continuity across edges is complex.

Any slight variation in glass tint, thickness, or printing pass can disrupt the uniform look.

🎯 Workarounds & Best Practices

Use vector patterns or high-resolution raster files designed for large-scale printing.

Test print sample panels before committing to a full façade.

Opt for ceramic frit digital printing for outdoor projects → it fuses into the glass and ensures permanence.

For interiors, UV-cured digital printing can achieve more vibrant photographic detail since durability demands are lower.

Digital In-Glass Printing Compare with Other Façade Materials

| Feature | Digital Printed Laminated Glass | ACP (Aluminium Composite Panel) | HPL (High Pressure Laminate) | Ceramic Frit Glass |

|---|---|---|---|---|

| Design Flexibility | Unlimited custom patterns, images, gradients with high resolution. | Limited to colors, metallic finishes, or PVDF coatings. | Printed textures available but less fine detail. | Patterns limited to dots, lines, or simple geometric frits. |

| Durability | High – laminated layers protect print, resistant to UV, fading, and weather. | Medium – prone to denting, scratching, and color fading over years. | Good – scratch resistant but surface can fade under UV. | High – frit is fused into glass, permanent and fade-resistant. |

| Safety | Laminated construction prevents shattering; safe for façades and skylights. | Not safety glass – cladding only. | Not structural glass – only cladding. | Tempered safety glass, but not laminated (may shatter). |

| Acoustic Insulation | Excellent – laminated interlayer reduces external noise. | Poor – offers little noise reduction. | Medium – some noise resistance due to thickness. | Medium – similar to tempered glass. |

| Thermal Performance | Can integrate Low-E, solar control coatings; patterns help reduce glare & heat. | Medium – depends on insulation behind panels. | Medium – some insulation but not solar control. | Good solar shading, but no thermal insulation. |

| Maintenance | Easy to clean, permanent surface; design does not peel or chip. | May require repainting or replacement over time. | Needs occasional maintenance; surface can degrade outdoors. | Easy to clean; design is permanent. |

| Sustainability | Long lifespan, recyclable glass, less replacement waste. | Not very eco-friendly; aluminum core often non-recyclable in composites. | Moderately eco-friendly, but replacement cycle is shorter. | Durable and recyclable glass. |

| Cost | Higher upfront but long-term savings (low maintenance + durability). | Low upfront cost, higher maintenance/replacement over time. | Medium cost, medium lifespan. | Medium-high cost, good lifespan. |

✅ Summary

Digital printed laminated sheets glass → Best for iconic designs, long-term durability, safety, and energy performance.

ACP → Cost-effective for simple façades, but shorter lifespan and less eco-friendly.

HPL → Good for budget projects, but limited design detail and durability outdoors.

Ceramic Frit Glass → Durable and fade-proof, but limited to basic patterns, not full customization.