Many of our clients may not be industry professionals, but they are very interested in the solar energy performance of coated glass. The following are some common points for your reference.

1-What forms of energy are present in solar radiation?

Solar radiation (also called sunlight or solar light) is composed of three main types of radiant energy: ultraviolet (UV) radiation, visible light, and infrared (IR) radiation.

Ultraviolet Radiation (UV):

With wavelengths between 0.3–0.38 μm, UV accounts for about 3% of total solar energy. It is invisible to the human eye. Prolonged exposure can cause skin burns, has a germicidal effect, and can also lead to the degradation of polymer materials.

Visible Light (VLT):

With wavelengths between 0.38–0.78 μm, visible light makes up around 47% of solar radiation. It is perceptible to the human eye but not the main carrier of heat. Different wavelengths correspond to different colors, ranging from red, orange, yellow, green, cyan, blue to violet. The colors seen in coated or reflective glass are achieved by interference technology, which adjusts the reflected wavelength.

Infrared Radiation (IR):

With wavelengths between 0.78–2.50 μm, infrared radiation represents about 50% of solar energy. Although invisible, it produces a strong heating effect and is the main carrier of solar heat energy, playing a crucial role in building energy efficiency and thermal comfort.

In summary, sunlight delivers roughly 50% light energy and 50% heat energy, while ultraviolet radiation has minimal impact on energy efficiency.

2-What does Visible Light Transmittance mean?

Within the visible light spectrum (wavelengths 0.38–0.78 μm), the ratio of the light intensity transmitted through glass to the incident light intensity is expressed by the symbol Tvis. This parameter, commonly referred to as visible light transmittance (VLT) or light transmittance, reflects the degree of transparency of coated glass building.

A higher visible light transmittance means that more natural light passes through the glass, which significantly improves indoor daylighting and visual comfort.

3-What does Visible Light Reflectance mean?

Within the visible light spectrum (wavelength 0.38–0.78 μm), the ratio of the intensity of light reflected by glass to that of the incident light is denoted by R, commonly referred to as the visible light reflectance or simply reflectance. It characterizes the extent to which glass reflects visible light. A higher reflectance indicates a stronger mirror-like effect of the glass and better visual shielding. For coated glass, the visible light reflectance differs between its two surfaces; therefore, in practical applications, the indoor reflectance (Ri) and outdoor reflectance (Ro) are distinguished.

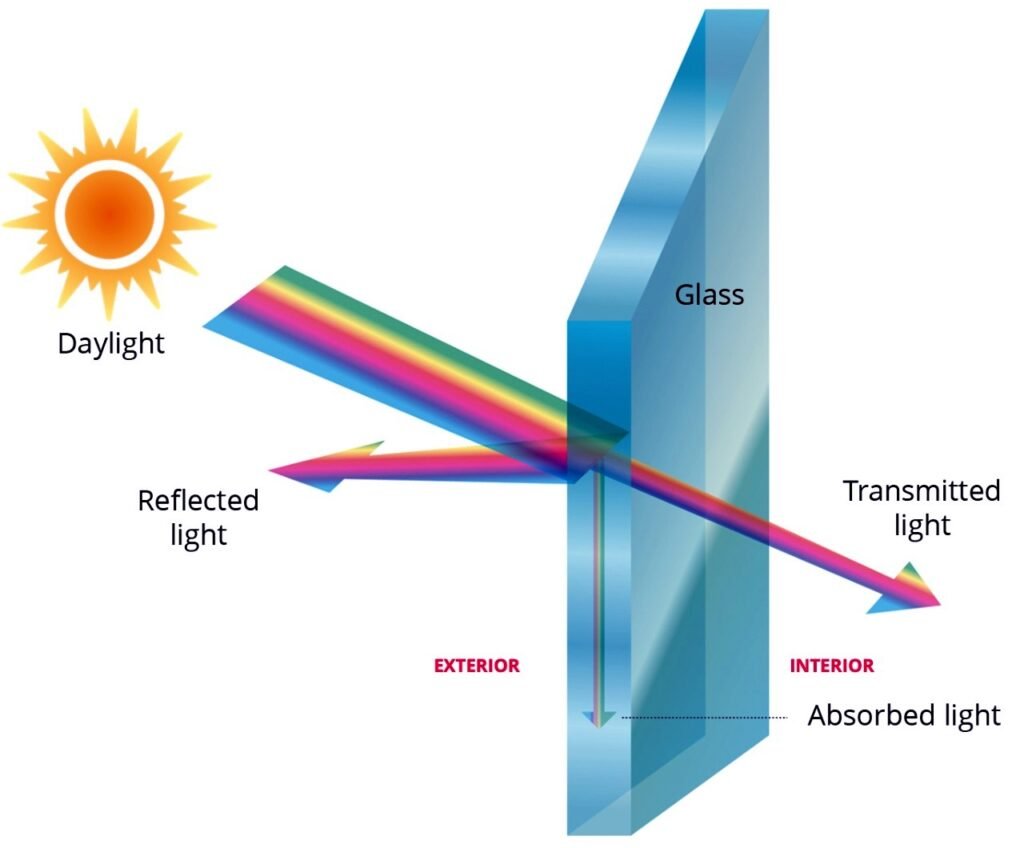

4-What is Solar Direct Transmittance?

Within the solar spectrum (wavelength 0.3–2.5 μm), the ratio of the solar radiation intensity transmitted directly through the glass to the incident solar radiation intensity is denoted by T, commonly referred to as the solar direct transmittance.

5-What is Total Solar Transmittance?

Within the solar spectrum (wavelength 0.3–2.5 μm), the ratio of the sum of (1) the solar radiation intensity directly transmitted through the glass and (2) the portion of absorbed solar energy subsequently re-emitted and transferred indoors, to the incident solar radiation intensity, is denoted by g. Unlike the solar direct transmittance, it additionally accounts for the secondary heat transfer from the glass into the interior space.

6-What is Solar Reflectance?

Within the solar spectrum (wavelength 0.3–2.5 μm), the ratio of the solar radiation intensity reflected by the glass to the incident solar radiation intensity, expressed as a percentage, is commonly referred to as the solar reflectance.

7-How is the Heat Transfer Through Glass Calculated?

The heat transfer through glass consists of two components: one is the solar heat gain transmitted indoors, including both directly transmitted solar radiation and the portion transferred indoors via secondary heat transfer; the other is the heat transfer caused by the temperature difference across the glass. The power of the heat transferred per unit area of glass can be calculated using the following formula:

Q/A=g⋅I+U⋅ΔT

where:

- Q/A = heat transfer power per unit area of glass (W/m²)

- g = total solar transmittance (solar factor)

- I = incident solar radiation intensity (W/m²)

- U = overall heat transfer coefficient of the glass (W/m²·K)

- ΔT = temperature difference between indoor and outdoor air (K)

8-What is the Heat Transfer Coefficient of Glass?

The heat transfer coefficient of glass, also known as the U-value, is defined as the amount of heat transferred per unit area of glass per unit time under steady-state conditions, when the temperature difference between the environments on both sides of the glass is 1 K (or 1 °C). Its unit is watts per square meter per kelvin, W/(m²·K).

The U-value is one of the primary parameters for evaluating the thermal performance and energy efficiency of glass. It is important to note that the U-value of glass refers only to the central area of the glass pane, without accounting for edge effects.

9-Which Aspect of Heat Transfer Does the Glass Heat Transfer Coefficient Reflect?

The heat transfer coefficient reflects the temperature-difference-driven heat transfer performance of the glass. It quantifies the heat flux through the glass caused by the temperature difference between the environments on both sides. Its value can be expressed as:

q=U⋅(T outside−T inside) W/m²

where q is the heat transfer per unit area through the glass, and U is the heat transfer coefficient. This represents the power of heat transfer through the glass due to the temperature difference.

10-What is the K-value of Glass, and How Does It Differ from the U-value?

Both the K-value and U-value represent the heat transfer coefficient of glass. In China, the standard system typically uses the K-value, while in European and American standards, the U-value is more commonly adopted.

The difference between the K-value and U-value does not lie in the physical meaning, but in the boundary conditions specified during the measurement of the heat transfer coefficient. As a result, the numerical values of the K-value and U-value for the same piece of glass may differ.

11-What Are the Testing Methods for the Heat Transfer Coefficient, and What Are Their Characteristics?

There are two main testing methods: spectral measurement and calculation and the hot box method.

1. Spectral Measurement and Calculation Method

This method measures basic parameters of a single glass pane using a spectrometer, including the solar transmittance spectrum, solar reflectance spectra of both glass surfaces, and the surface emissivity of the glass. The heat transfer coefficient is then calculated based on the glass’s combination structure using specialized thermal calculation software.

Advantages:

- Requires only small sample size (e.g., 100 mm × 100 mm)

- Only a single glass pane needs to be tested

- Can calculate parameters for different glass combinations

- Provides accurate results

- Low testing cost

This method is widely adopted internationally.

2-Hot Box Method

This method uses a hot chamber and a cold chamber, with the glass sample placed between them. After setting the required parameters, the heat flux is measured and used to calculate the heat transfer coefficient of the glass.

Advantages:

- Provides the heat transfer coefficient of the entire specimen

- Simulates real environmental conditions

Disadvantages:

- Requires large sample size

- Long testing time

- Higher measurement error

- Results apply only to the tested glass structure

- High testing cost

12-Which Boundary Conditions Affect the Measurement of the Heat Transfer Coefficient?

The measurement of the glass heat transfer coefficient is closely related to the boundary conditions, including the air temperature on both sides of the glass, outdoor wind speed, indoor air flow, and solar radiation intensity. In real-world applications, glass is exposed to various complex environmental conditions. However, as a comparative parameter for evaluating the energy performance of glass, standardized boundary conditions can be specified to provide a consistent basis for comparison. These boundary conditions are defined by the standards for measuring the heat transfer coefficient.

13-What Are the Common Standards for Measuring the Heat Transfer Coefficient of Glass?

In China, measurements are primarily based on the “Thermal Performance Calculation Code for Building Doors, Windows, and Curtain Walls” (JGJ 151) and the boundary conditions specified by the Building Doors and Windows Energy Performance Labeling Committee under the Ministry of Housing and Urban-Rural Development.

In Europe, measurements are typically conducted according to the EN 673 standard (ISO 10292), while in North America, the NFRC 100 or ASHRAE standards are commonly used. Other countries often adopt American standards.

For domestic building energy efficiency acceptance in China, the JGJ 151 method and the boundary conditions specified by the national labeling committee are used. For participation in international green building certification, measurements should follow the NFRC 100 or EN 673 standards.

👇

Contact Xpert BM to get more information anytime.

- sales@xpertglazing.com

- +86 15711964309