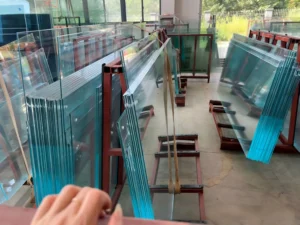

What is Heat treated glass?

Heat treated glass, also called tempered toughened glass, which is a type of safety glass that is heat-treated to increase its strength and durability. Through a process of heating to over 600°C followed by rapid cooling, tempered glass becomes up to five times stronger than regular annealed glass.

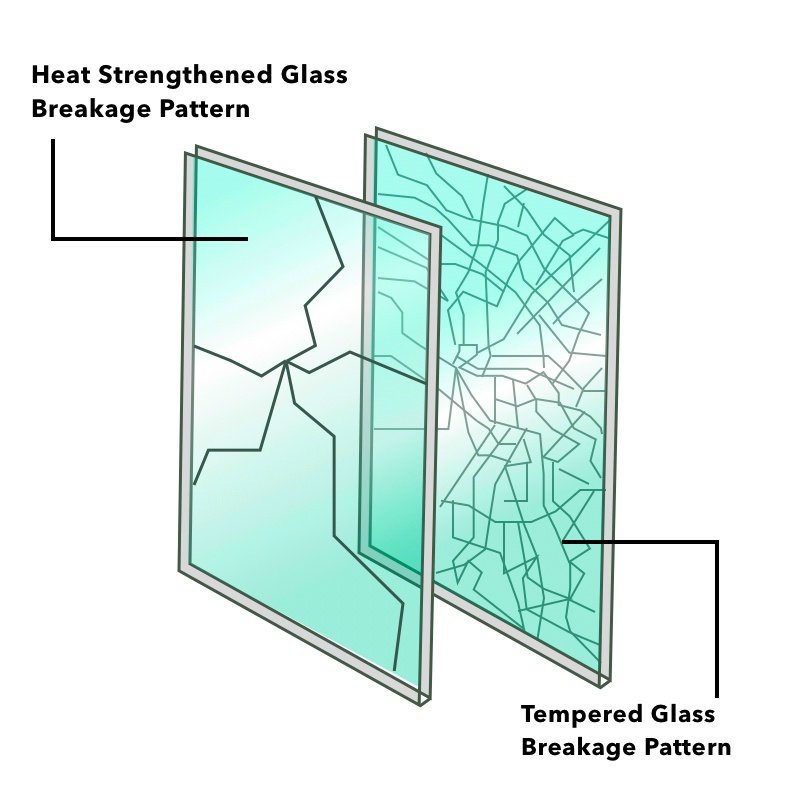

One of its key safety features is how it breaks — instead of sharp shards, it shatters into small, blunt pieces, greatly reducing the risk of injury.

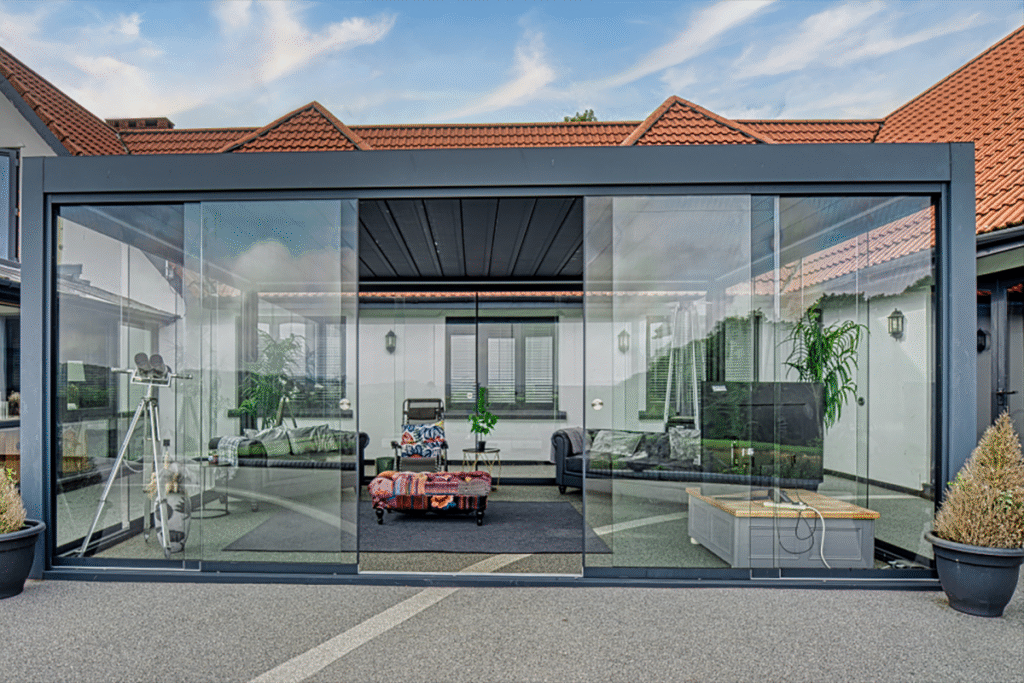

Tempered glass is widely used in building facades, doors and windows, shower enclosures, partitions, furniture, and automotive glass — wherever strength, thermal resistance, and safety are required.

Items for Heat treated glass

Fully tempered glass also called toughened glass or tempered safety glass, which is a type of safety glass that has been heated to high temperatures and then rapidly cooled to increase its strength. It’s about 4 to 5 times stronger than regular glass. When broken, it shatters into small, blunt pieces that are less likely to cause injury.

- High Strength

Significantly stronger than ordinary glass, offering excellent impact and bending resistance.

- Enhanced Safety

Breaks into small, harmless fragments—ideal for applications where human safety is a priority.

- Superior Heat Resistance

Can withstand rapid temperature changes of over 200°C, making it perfect for high-heat or sun-exposed environments.

Heat strengthened glass, also known as semi-tempered glass or half-tempered glass, is glass that has been heat-treated to improve its strength. It’s about twice as strong as regular annealed glass, but not as strong as fully tempered glass. When broken, it cracks into larger fragments but generally remains in the frame, offering structural stability and added safety.

- Excellent Thermal Stability

Can withstand temperature differences of over 150°C, making it ideal for facades and building exteriors.

- Cracks but Holds Together

Breaks with visible cracks but stays in place, reducing the risk of falling glass.

- Good Wind Load Resistance

Suitable for large curtain wall systems where high wind pressure performance is required.

Heat soaked tempered glass is fully tempered glass that has undergone a Heat Soak Test (HST glass). During this process, the glass is held at around 250°C for several hours to trigger the breakage of panes that contain nickel sulfide (NiS) inclusions, which are known to cause spontaneous breakage. This significantly reduces the risk of glass exploding unexpectedly after installation.

- Reduced Risk of Spontaneous Breakage

The HST process eliminates glass with nickel sulfide inclusions, minimizing the chance of unexpected failure.

- High Safety and Reliability

Ideal for high-rise buildings, curtain walls, overhead glazing, and other safety-critical applications.

- Maintains Full Tempered Strength

Even after heat soaking, the glass retains its original strength, impact resistance, and thermal durability.

Curved tempered glass is a type of safety glass that is heated until soft and then bent into a specific shape using custom molds before being rapidly cooled. It combines the strength and safety of tempered glass with the elegance and flexibility of curved design. This glass is commonly used in curtain walls, railings, showcases, revolving doors, and other architectural or decorative applications requiring a curved form.

- Customizable and Aesthetic Design

Can be shaped into various curves to meet architectural and design requirements.

- High Strength and Safety

Offers excellent impact and thermal resistance, and breaks into small, blunt fragments for safety.

- Versatile Applications

Ideal for curved facades, railings, bridges, shopping displays, and more.

Hot bent glass refers to glass that has been heated to a high temperature and then shaped or bent into a specific form using molds or other tools. This process allows the glass to be permanently altered without breaking. It’s often used for architectural applications like curved windows, facades, or automotive glass, where a smooth, seamless curve is desired. The heating process makes the glass pliable, and once it cools, it retains its new shape. The result is a durable, custom-shaped glass that can fit particular design needs.

Cold bent glass refers to flat glass that is bent or curved into shape without heating, by applying mechanical force during installation. Instead of using high temperatures like in hot bending, the glass is gently flexed into a curved frame or support structure while remaining at room temperature.

- The bending happens on-site during installation.

- It requires thin, flexible glass (typically annealed or laminated).

- The glass is held in place by the frame, which maintains the curve.

- This method is cost-effective compared to hot bending.

- It’s ideal for large, gently curved surfaces, like modern glass facades.

However, cold bent glass has limitations — it can only achieve mild curves and requires precise engineering to avoid stress cracks over time.

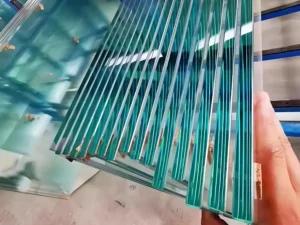

Specification for heat treated glass

| Item | Description |

|---|---|

| Glass Thickness | 3mm, 3.2mm, 4mm, 5mm, 6mm,. 8mm, 10mm, 12mm, 15mm, 19mm, 22mm, 25mm |

| Glass Dimension | Maximum: 3300x9000mm, minimum: 100x100mm |

| Glass Color | Clear, ultra clear, french/dark green, ford/dark blue, dark/light gray, light/golden bronze, dark bronze, pink, black, etc |

| Glass Type | Clear float glass, Low E glass, patterned glass, frosted glass, mirror. |

| Delivery Time | Standard size: 3-7 days minimum, complex orders: 10-15 days |

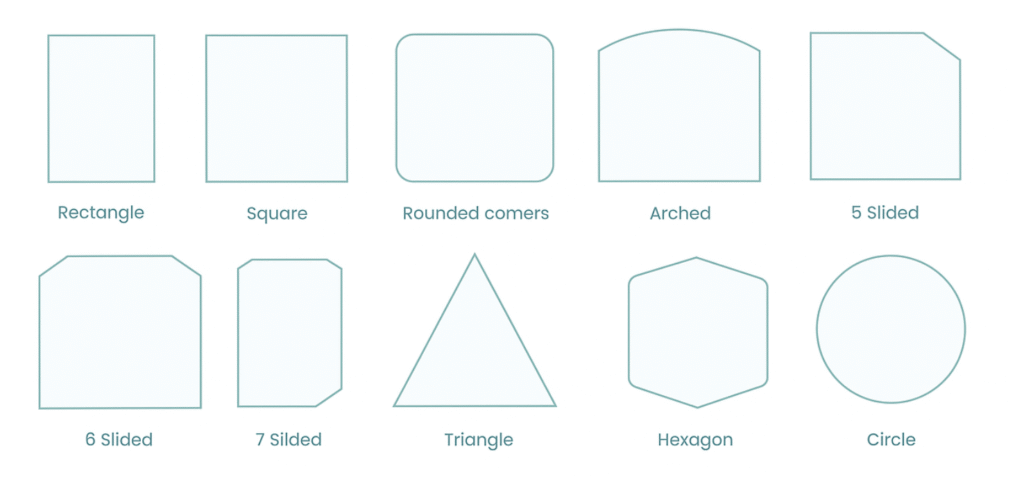

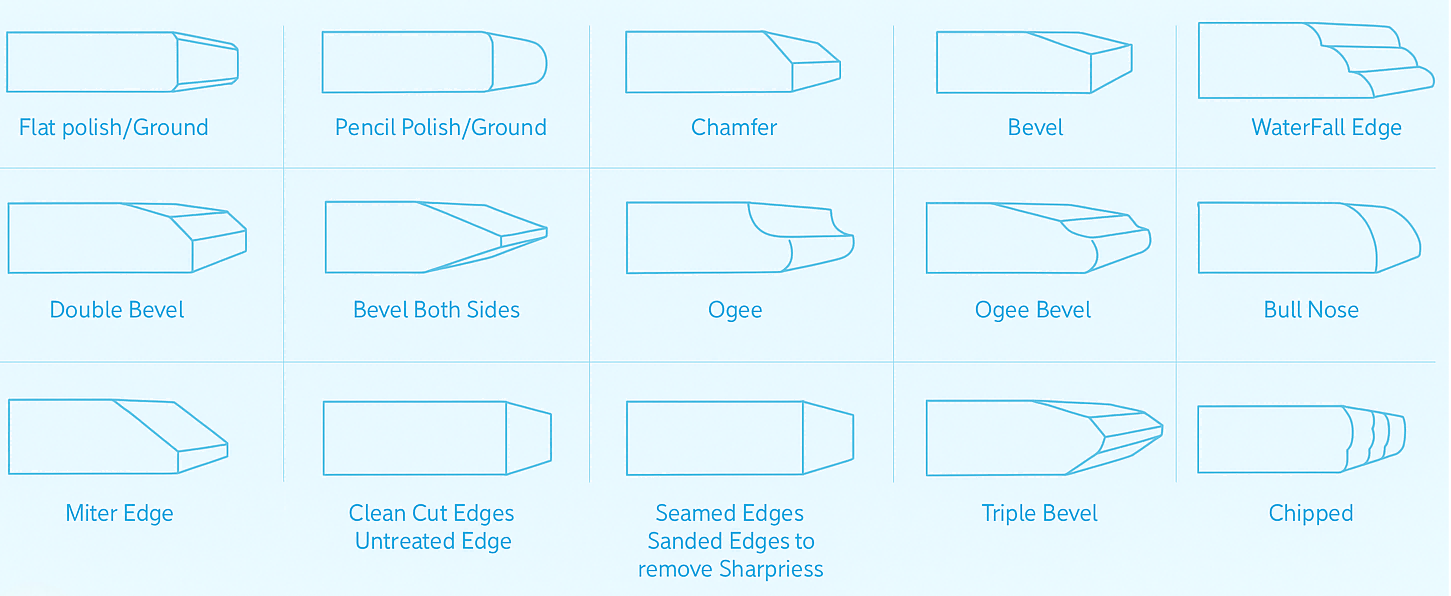

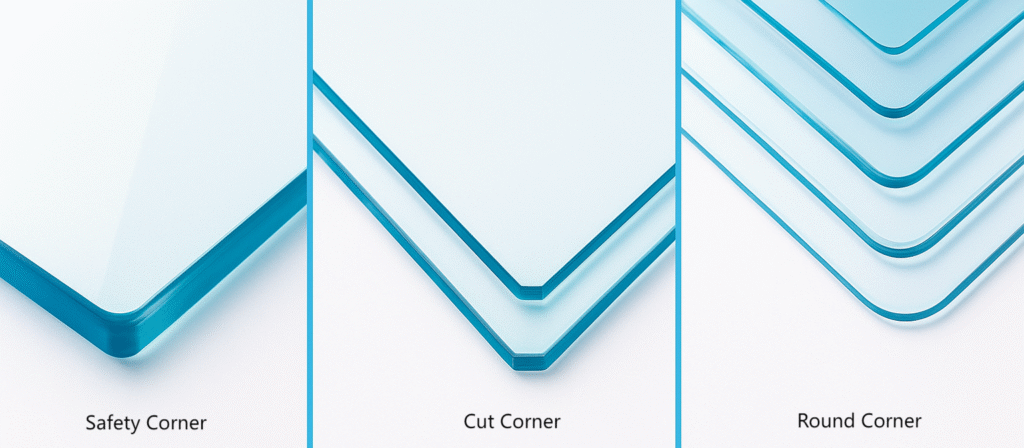

After the glass is manufactured, its four corners are typically very sharp. If installed without framing in certain projects or products, exposed corners may pose a risk of accidental injury. For applications such as furniture or in high-traffic areas where people frequently come into contact with the glass, we strongly recommend corner treatment to enhance safety.

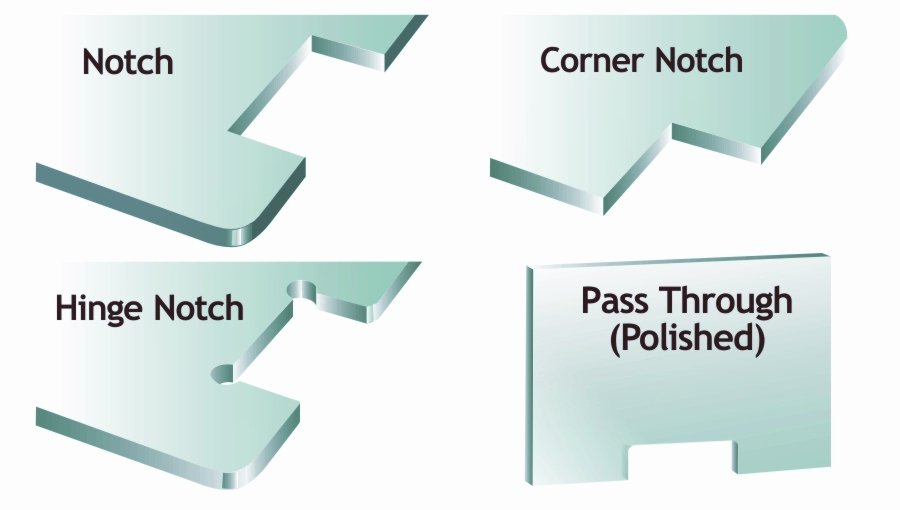

Holes and cutouts in glass are designed to allow seamless integration with hardware components, ensuring better installation performance. If you need more professional advice on hardware selection, feel free to contact our hardware team — we’re confident they can offer you valuable insights and ideas.

Related Product

-

Product: 8mm Starfire Glass Shower Doors Thickness: 8mm, 5/16 Inch...

-

Product: 10mm Framed Glass Custom Shower Doors Thickness: 10mm, 3/8...

-

Product: Perfect 12mm Transparent Toughened Glass for Office Thickness: 12mm,...

-

Product: Nice Wholesale Price 12mm Padel Court Glass Thickness: 12mm,...

Absolutely. Our tempered glass complies with international standards such as EN12150, ANSI Z97.1, and ASTM C1048. Upon request, we can provide quality inspection reports, fragmentation test results, and certificates of conformity. For projects that require additional assurance, we also offer heat soak test certificates.

Our MOQ varies depending on the product type and specifications. For standard tempered glass, we can usually accommodate small trial orders. For large-size or customized glass, we may require a higher MOQ. Feel free to contact us with your requirements, and we’ll offer flexible options.

Yes, we offer full customization including irregular shapes, drilled holes, notches, and cutouts for hardware fittings. Just provide detailed drawings (preferably in CAD or PDF format), and our team will handle the rest with precision cutting and polishing.