In the glass manufacturing industry, delamination and bubbles are the most prevalent defects in PVB laminated glass. According to internal statistics from glass manufacturers, these defects account for over 20% of total waste during production. More significantly, they represent over 80% of customer complaints during the product’s service life.

For instance, in a specific project involving 56m2 of defective glass, 50m2 (89%) were due to delamination and bubbles. To eliminate these issues, it is critical to analyze the root causes based on the type and location of the defects.

1. Classification of Bubbles and Delamination of PVB Laminated Glass

Type 1: Edge Delamination and Bubbles

This is the most common defect, accounting for 15% of production waste and over 85% of post-installation complaints.

-

Production Causes: Poor edge sealing after nip rolling; excessive rolling speed; low rolling temperature (cold glass); premature pressure release in the autoclave; excessive edge deformation of tempered glass; or PVB patterns that are too fine for effective air evacuation.

-

Post-Installation Causes: High humidity/heat environments; contact with incompatible structural sealants; exposure to acetic acid, alcohols, or ketones; excessive mechanical clamping during production; and poor compatibility or adhesion of ceramic frit (on silk-screened glass).

Type 2: Dispersed Bubbles in the Center

These defects are typically related to the preparation process and PVB storage.

-

Production Causes: Incomplete air evacuation during nip rolling; excessive rolling speed; PVB film with moisture content exceeding standards; or insufficient PVB thickness.

-

Service Life Causes: “Re-bubbling” caused by residual air trapped during rolling; high PVB moisture content weakening the glass-to-film bond; or poor adhesion between the ceramic frit and the glass/PVB.

Type 3: Combined Edge and Center Bubbles

Often found in non-matched tempered laminated glass, where the glass plates do not align perfectly.

-

Production Causes: Poor glass flatness/matching; thin PVB film; premature sealing due to slow rolling; poor nip rolling performance; or excessive mechanical pressure on edges.

-

Service Life Causes: Residual stress (beyond permanent tempered stress) from improper processing, low-quality PVB with poor adhesion, or unreasonable structural installation.

2. Equipment Management Optimization of PVB Laminated Glass

To minimize risks, manufacturers must focus on the two core machines: the Nip Roller and the Autoclave.

The Nip Roller (Pre-pressing)

The nip roller’s role is air evacuation and edge sealing.

-

Uniform Heating: Ensure all heating elements work correctly for even glass temperature.

-

Roller Calibration: The gap between the upper and lower rollers (pre-press and final press) must be consistent to ensure proper sealing.

-

Temperature Accuracy: Regularly calibrate sensors to ensure the display matches actual glass surface temperatures.

The Autoclave (Final Pressing)

-

Pressure/Heating Balance: Adjust heating and pressurization rates based on the loading rate and the quality of the pre-sealed edges.

-

Soaking Phase: Maintain 135°C–140°C to allow PVB flow, filling gaps caused by glass deformation and absorbing residual air.

-

Cooling Phase: Keep pressure constant during cooling to prevent edge bubbles.

-

Discharge Temperature: Air should be exhausted only when the temperature is below 45°C (glass surface < 40°C).

-

Air Quality: Use oil-free and moisture-free compressed air.

3. Material Quality Control Causes the Laminated Glass Delamination Problem

PVB Laminated Glass Quality

Over 95% of PVB laminated glass uses tempered glass. Its flatness is vital:

-

Warp and Bow: Must be strictly controlled (the lower, the better).

-

Matched Tempering: PVB Laminated Glass intended for lamination should be tempered in pairs to ensure matching curvature.

-

Surface Stress: Keep surface stress at the lower end of the standard range to reduce deformation and spontaneous breakage risks.

PVB Interlayer Quality

-

Standard Compliance: Must meet GB 15763.3-2009 or equivalent international standards.

-

Pattern/Texture: The embossing should be uniform—neither too fine (traps air) nor too coarse (hinders sealing).

-

Moisture Content: Must be kept below 0.45%. High moisture severely degrades the bonding strength.

PVB Thickness Selection

Thicker PVB films are recommended for tempered glass to compensate for “bow” and “warp” deformations. Using a thicker film reduces permanent tensile stress at the edges, significantly lowering delamination risks.

| Recommendations for the Selection of Annealed PVB Laminated Glass Film Thickness | |||

| Item | Base Type (mm) | Thickness of PVB (mm) | |

| Short Side ≤800mm |

Short Side >800mm |

||

| Annealed Laminated Glass | ≤6 | 0.38 | 0.38 |

| 8 | 0.38 | 0.76 | |

| 10 | 0.76 | 0.76 | |

| 12 | 1.14 | 1.14 | |

| ≥15 | 1.52 | 1.52 | |

| Recommendations for Selecting the PVB Thickness of Tempered (Fully Tempered, Semi-Tempered) Laminated Glass | ||||

| Item | Base Type (mm) | Thickness of PVB (mm) | ||

| Short Side ≤800mm |

800<Short Side ≤1500mm |

Short Side >1500mm |

||

| Toughened Laminated Glass | ≤6 | 0.76 | 1.14 | 1.52 |

| 8~12 | 1.14 | 1.52 | 1.52 | |

| ≥15 | 1.52 | 2.28 | 2.28 | |

| Recommendations for Selecting the PVB Thickness of Curved Laminated Glass | |||

| Item | Base Type (mm) | Thickness of PVB (mm) | |

| R>3000mm | R≤3000mm | ||

| Bent Toughened Laminated Glass | ≤8 | 2.28 | 3.04 |

| ≥10 | 3.04 | 3.04 | |

| Bent Glass | ≤6 | 0.76 | 1.14~1.52 |

| ≥8 | 1.14 | 1.52 | |

4. Process Control Analysis for PVB Laminated Glass

Cleaning (Washing)

-

Deionized Water: Conductivity should be < 30 $\mu$s/cm. High calcium/magnesium levels hinder the formation of hydrogen bonds between the glass and PVB.

-

Water Temp: Maintain between 40°C–50°C.

Lay-up Room Environment

-

Temperature: 18°C – 28°C.

-

Humidity: 18% – 28% RH.

-

Cleanliness: Maintain a dust-free, positive-pressure environment.

-

Film Overhang: Leave a 3mm–5mm margin to prevent shrinkage.

Nip Rolling Parameters

-

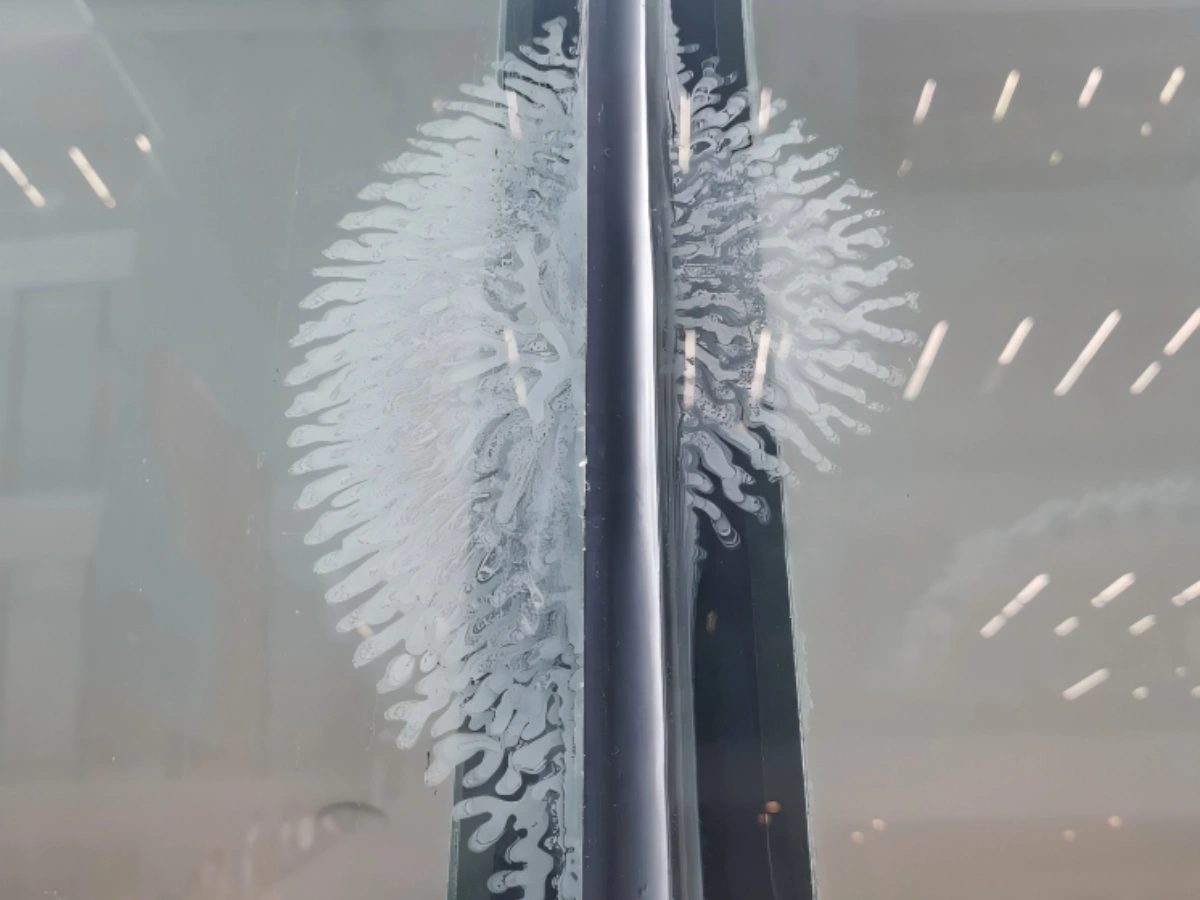

Visual Check: A successful pre-press should show a 20mm–30mm transparent border, while the center remains translucent.

-

Gap Settings: The first roller gap should be ~10% smaller than the total glass thickness; the final roller gap should be 15%–20% smaller.

-

Surface Temp: Glass should exit the roller at approximately 70°C.

Autoclave Parameters

-

Temperature/Pressure: 135°C–140°C at 12–14 bar.

-

Duration: 60–120 minutes, depending on loading density and glass thickness.

-

Cooling Rate: 1°C/min – 2°C/min.

Conclusion

Delamination and bubbles are the primary quality hurdles for PVB laminated glass. By optimizing equipment maintenance, material selection, and process parameters, manufacturers can significantly improve yield rates and product longevity.

Get Premium, Defect-Free Laminated Glass for Your Projects

At Xper BM, we understand that quality is the foundation of every architectural masterpiece. Our manufacturing process follows the strictest standards to ensure that every piece of PVB laminated glass is free from bubbles, delamination, and structural flaws.

Whether you are looking for high-performance safety glass or need technical advice for your next large-scale project, our team of experts is ready to assist.

Contact us today for a professional consultation or a competitive quote:

-

📧 Email: sales@xperglazing.com

-

💬 WhatsApp: +86 15711964309

Xper Building Material — Precision. Quality. Reliability.