Congratulations to Xpert BM on completing another project, a mid-sized hotel project all aluminum door with window. Despite the challenges throughout the process, Xpert’s BM and customer teams worked side-by-side to overcome all difficulties.

This project is located in a mid-sized hotel on Visayas Island in the Philippines. The owner plans to use it as a template to replicate more similar hotels if this project is completed. Of course, this involves many difficulties.

1-Why is it difficult to manufacture aluminum door with window systems that can withstand the Philippines’ typhoon-grade wind loads?

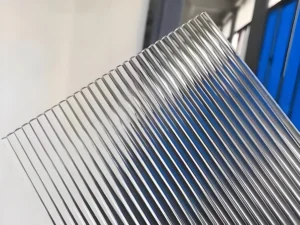

We often struggle because Philippine coastal and island regions are exposed to intense typhoons with extremely high wind pressures. Our clients’ hotels require reinforced frames, thicker profiles, certified glazing, and precise structural calculations, which significantly complicate the production process.

Ensuring compliance with national building codes and local government wind-load requirements further increases technical complexity.

2-What challenges arise from the country’s high humidity, salt exposure, and tropical climate?

The Philippines’ climate accelerates corrosion, especially in seaside cities like Cebu, Iloilo, and Palawan. Aluminum doors with windows frames, hardware components, rollers, hinges, and glass curtain wall brackets can degrade much faster if not treated properly. We must apply specialized coatings, choose corrosion-resistant alloys, and adjust fabrication methods, which heightens production costs and technical demands.

3-Why they difficult to source high-quality, high-performance aluminum doors with windows locally?

High-performance insulating glass, low-E coatings, and laminated safety glass are not always readily available from local suppliers. They need to rely on imports, which introduces long lead times, higher costs, and possible delays at customs. This makes scheduling fabrication for hotel projects unpredictable, especially for aluminum doors with windows that require consistent batch quality.

For Xpert BM, we are in Guangdong, China. It’s very fast when shipped to Cebu port, only 5-6 days is enough, also, the production is all based on advanced auto machines, which can decrease the actual lead time, less than 30 days.

4-How do inconsistent local material standards affect manufacturing?

Mid-sized hotels often expect international-grade performance, but local manufacturing standards may vary among suppliers. Achieving uniform tolerances, proper sealing performance, and exact color matching can be difficult.

This inconsistency forces manufacturers to perform more stringent quality control and adjust production processes, extending project timelines.

Xpert BM joined forces with the local installation company, and knows more about that, and ensures the right products they received and also need to meet the local policy.

5-Why does customizing designs for a hotel’s architectural concept create manufacturing complications?

Hotels usually demand personalized facade aesthetics—unique mullion spacing, specialized coatings, non-standard panel sizes, or signature lobby glazing. Custom work requires specialized tooling, engineering recalculations, and prototype testing. Such customizations often slow down production and increase the risk of fabrication errors due to the lack of mass-production efficiency.

Actually, Xpert BM also meet the problem like that, after a neggotiation with the client, from the perspective of safety and durability, we strive to meet our customers’ requirements to the greatest extent possible. For modules that require visibility, we employ alternative solutions.

6-How do supply chain interruptions and logistics challenges affect fabrication?

The Philippines’ archipelagic geography can complicate delivery of raw materials and finished products. Transporting large aluminum doors with windows panels and oversized glazing between islands requires specialized handling, increases the risk of damage, and can delay delivery.

These logistical uncertainties force manufacturers to build in large safety buffers during fabrication planning.

The Xpert BM team has extensive experience in exporting glass and building materials, especially aluminum door with window, as these products require very specialized packaging and excellent container loading details. We have handled the loading of no fewer than 2,000 containers, so you can entrust this to us with confidence.