Laminated Safety Glass

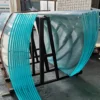

If you are searching for premium-grade 664 Bent Curved Laminated Glass, designed for architectural excellence and high-strength performance, Xpert BM is your trusted supplier in China.

Our 13.52mm tempered laminated curved glass combines exceptional durability, precise bending capabilities, and enhanced safety for modern commercial and residential applications.

What is 664 Bent Curved Laminated Glass?

664 Bent Curved Laminated Glass refers to a laminated safety glass structure composed of two 6mm tempered glass layers bonded with a 1.52mm PVB interlayer, then heated and formed into a smooth, controlled curve.

This glass structure is commonly expressed as:

6mm + 1.52mm PVB + 6mm = 13.52mm laminated curved glass (2.28mm PVB also available)

During production, each glass layer is toughened (tempered) to increase strength, then laminated for added impact resistance and safety. Bending is achieved through precision molds that allow custom curvature—from gentle arcs to tight radius.

It is widely used in architectural façades, balustrades, skylights, canopies, partitions, glass railings, and bespoke interior installations.

Arc Length 500mm X Height 2440mm | R>200mm, thickness limit 3mm, 4mm, 5mm |

Arc Length 1600mm X Height 3300mm | R>600mm |

Arc Length 7000mm X Height 3300mm | 3000mm Arc Length, Radius>1500mm,7000mm Arc Length, Radius>3000mm |

Arc Length 3000mm X Height 7000mm | Convex – Radius>1500mm,Concave – Radius>1800mm |

Arc Length 2800mm X Height 7000mm | Multi-curved glass, to be confirmed |

Arc Length 3000mm X Height 130000mm | R>1200mm |

Processing Flow for 664 Bent Curved Laminated Glass Supplier

Features of 664 Bent Curved Laminated Glass

Exceptional Strength & Safety

The combination of tempered glass and a strong PVB interlayer ensures high impact resistance and maximum personal safety.Smooth, Accurate Curve Quality

Each panel is bent using precision forming technology, guaranteeing consistent curvature, optical clarity, and structural stability.UV & Acoustic Protection

The PVB layer blocks up to 99% of UV radiation and helps reduce noise transmission—ideal for high-traffic or sunny environments.Customizable Radius, Size & Shape

Available in tight, medium, or wide radius curves. Fully customizable to your project drawings.Weather & Heat Resistant

Designed for extreme outdoor climates, including high UV, heavy rainfall, coastal humidity, and fluctuating temperatures.Shatter-Safe

Even when broken, the glass fragments bond to the PVB layer, preventing dangerous shattering.

Specification for 13.52mm 664 Bent Curved Laminated Glass

| Specification Item | Detailed Description |

|---|---|

| Product Name | 664 Bent Curved Laminated Glass |

| Structure | 6mm Tempered Glass + 1.52mm PVB + 6mm Tempered Glass |

| Total Thickness | 13.52mm Tempered Laminated Curved Glass |

| Glass Type | Tempered (Toughened) Laminated Curved Glass |

| Standard Colors | Clear, Ultra Clear (Low-Iron), Grey, Bronze, Blue, Green |

| PVB Interlayer Options | Clear PVB, Milky White, Colored PVB, Acoustic PVB |

| Curvature Radius | Custom (Minimum radius typically 700–1500mm depending on size) |

| Max Size | Up to 2440mm x 4000mm (custom sizes available) |

| Edge Processing | Flat-polished, beveled, arrised edges |

| Safety Rating | EN 14449 / EN 12150 / ASTM C1172 / AS/NZS 2208 compliant |

| Impact Resistance | 3–5x stronger than regular curved annealed glass |

| Light Transmission | 80–92% depending on glass type |

| Heat Resistance | Withstands temperature differences up to 250°C |

| Applications | Curtain walls, balustrades, canopies, domes, railings, partitions, skylights, storefronts, interior décor |

| Installation Compatibility | Spider fittings, clamps, U-channel, embedded mounting, frames |

Different 6+1.52+6mm 664 Bent Curved Laminated Glass Types

How Many 6+6mm 664 Bent Curved Laminated Glass Types You Can Find From Xpert BM?

At Xpert BM, we provide one of the most extensive selections of 6+6mm laminated curved glass in Asia. You can request:

Tight Radius 664 Bent Curved Laminated Glass for stair railings and small structures

S-Shaped and Wave-Form 664 Bent Curved Laminated Glass

Cylindrical & Tunnel-Type 1/2 inch bent toughened laminated glass

Convex or Concave 664 Bent Curved Laminated Glass

Jumbo-Size Oversized 1/2 inch bent toughened laminated glass

Custom Colored Curved Glass with PVB Tint Options

Every type is available in clear, ultra-clear, tinted, frosted, or reflective options, depending on the project’s aesthetic or energy-efficiency goals.

Xpert BM ensures every piece of 664 bent curved laminated Glass arrives safely, regardless of global destination.

Export-grade plywood crates with reinforced steel strapping

Cork spacers / foam protection between each panel

Moisture-proof plastic film wrapping

Edge and corner guards for high-curvature areas

Shock-proof internal buffering materials

Clear labeling for size, radius, direction, and installation orientation

All crates meet international shipping standards for sea freight, land transport, and air cargo.

Xpert BM is here to support your 6mm+1.52PVB+6mm curved laminated glass project—from design consultation to global shipment.

For quotations, drawings, or technical support, contact us anytime:

📧 Email: sales@xpertglazing.com

📱 WhatsApp: +86 15711964309

Tell us your project requirements and get an expert quote within 24 hours!

FAQs for Order 13.52mm 664 Bent Curved Laminated Glass

For a first-time cooperation, we are happy to provide free samples for simple products such as clear tempered glass and clear laminated glass to support our initial collaboration. However, we are unable to cover the shipping costs. We hope both sides can share some of the expenses from a partnership perspective. If this order and project move forward and we work together in the future, these costs can be fully deducted from our formal cooperation.

In general, this is not a problem. Please contact us using the form below, and our team will get in touch with you.

Additionally, please note that our partner suppliers are located in various regions across China, and the glass and aluminum factories in particular are often situated in relatively remote areas. Visiting them in person can be costly overall. If you would like to save time and effort, we can arrange to visit them on your behalf under your company’s name.

Yes, we do offer door-to-door service. We can arrange it according to your location, and the exact cost and lead time will be confirmed based on the destination and shipping method you prefer.

The shipping cost depends on the destination, product type, and shipping method (air, sea, or express).

For large or heavy items like glass, window, door, curtain wall, sea freight is usually the most cost-effective option. While international shipping can be a significant part of the total cost, we always work to find the most economical and efficient solution for our customers and can provide a detailed quotation for your reference.

For tempered glass and standard laminated glass, we generally offer a 5-year warranty. For higher-performance glass, such as insulated glass, Low-E glass, and coated glass, we typically provide a 10-year warranty.

Please note: As glass is inherently fragile, there is always a risk of breakage during transportation. Even for tempered glass, despite our use of high-quality raw glass from XYG, CSG, and PPG, and processing with advanced tempering furnaces from NorthGlass and LandGlass, there is still an approximate 0.2% risk of spontaneous breakage. If any damage occurs, we will do our best to assist you in minimizing the loss.

Yes. 13.52mm curved laminated tempered glass is commonly used for balustrades, spiral staircases, bridges, and protective barriers. The PVB interlayer ensures safety even in the unlikely event of breakage.

Yes. In addition to standard clear and milky-white PVB, we offer a wide range of colored PVB options—grey, green, blue, bronze, yellow, pink, or fully customized tones. For premium aesthetics, we can also incorporate SentryGlas (SGP), EVA, or decorative films, including gradient films, mesh patterns, or fabric interlayers, depending on your design needs.

Once the glass is tempered and bent, it cannot be cut, drilled, or reshaped. All fabrication—including holes, notches, cutouts, edge treatment, and sensor installation—must be completed during the pre-tempering stage. Be sure to confirm all hardware positions before production to avoid delays.

Yes. We frequently produce mock-up panels (MUPs) for project testing, ESG/ASTM compliance checks, or on-site structural evaluations. Small quantity production is available, allowing architects to verify aesthetics, fit, curvature, and hardware compatibility before mass production.