What process is used to manufacture low-emissivity coated glass?

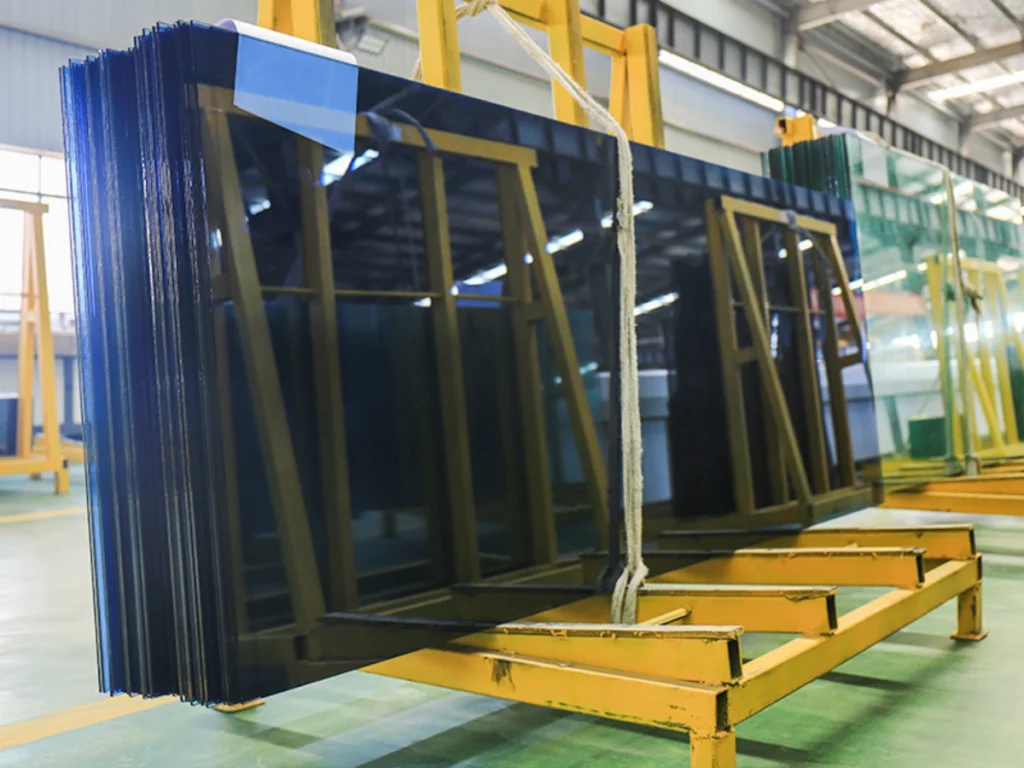

Low-emissivity coated glass, commonly referred to as Low-E glass, is produced by applying a thin film with low emissivity properties onto the surface of the glass through physical or chemical processes. In industry, it is called Low Emissivity Coating, hence the term ‘Low-E glass’. At present, the mature commercial manufacturing techniques for Low-E coated glass include vacuum magnetron sputtering (a physical method) and chemical vapor deposition (a chemical method)

What is online Low-E glass, and what are its main features?

Online Low-E glass refers to Low-E coated glass produced directly on the float glass manufacturing line, where a Low-E film is applied in the high-temperature zone during glass formation using chemical vapor deposition (CVD) technology. Because the coating process is completed as part of the flat glass production line, this type of low-emissivity glass is called on-line Low-E glass. Its low-emissivity functional layer consists of semiconductor compounds.

The advantages of on-line Low-E coatings include strong adhesion between the coating and the glass surface due to the high-temperature application, as well as excellent scratch resistance, allowing the glass to be used as single glazing—hence the term “hard coating.” However, its drawbacks include lower precision in controlling film thickness, making it impossible to create multilayer interference coatings that selectively control the solar spectrum transmitted through the glass. Additionally, the coating’s reflected color is limited, and its emissivity is relatively high (greater than 0.15).

What is offline Low-E glass, and what are its key features?

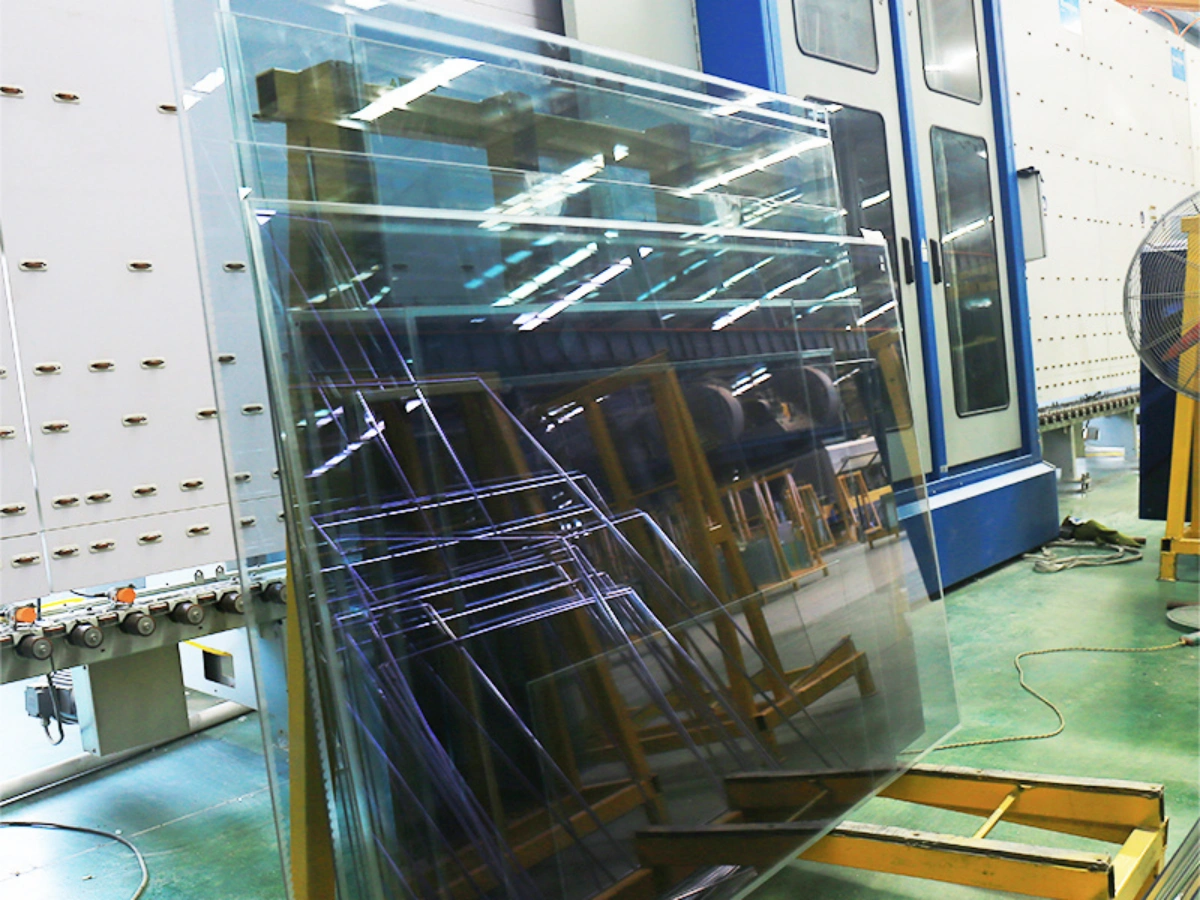

Offline Low-E glass is produced on a vacuum magnetron sputtering coating line. The principle involves depositing a thin film onto the glass surface in a vacuum environment, where a negative high voltage and working gas generate plasma to transfer solid material (the target) onto the glass. When the working gas is argon, the deposited film has the same composition as the target material; when the working gas is a reactive gas such as oxygen or nitrogen, the deposited film is a compound formed by the reaction between the target material and the gas.

Most coating lines are equipped with multiple targets of different materials, enabling the continuous deposition of individual layers that can be stacked into multilayer composite coatings.

Because the coating process is completed on a separate coating line, this type is called “off-line Low-E glass,” with the low-emissivity functional layer typically consisting of a silver metal layer. Its advantages include precise control over film thickness, the ability to produce multilayer optical interference coatings to selectively control the solar spectrum transmitted through the glass, a wide range of adjustable reflective colors, and a low emissivity (less than 0.15).

Its disadvantages include lower film hardness and poor corrosion resistance, hence the term “soft coating.” It should be noted that the latest off-line silver-free Low-E coating technology offers enhanced wear and corrosion resistance, allowing the coated surface to face indoors. This type is commonly referred to as “silver-free Low-E” or “interior Low-E coating.”

Comparison of On-line and Off-line Low-E Glass

| Item | On-line Low-E Glass | Off-line Low-E Glass |

|---|---|---|

| Definition | Produced on the float glass production line by applying a Low-E coating in the high-temperature forming zone using Chemical Vapor Deposition (CVD). | Produced on a separate vacuum magnetron sputtering coating line under vacuum conditions. |

| Coating Process | CVD in the hot zone of float glass manufacturing. | Magnetron sputtering deposition in a vacuum chamber. |

| Functional Layer Material | Semiconductor compounds. | Typically a silver (Ag) layer; advanced technology also allows silver-free coatings. |

| Adhesion & Durability | Strong bond with glass surface; highly scratch-resistant; also called hard coating; can be used as single glazing. | Lower hardness and poorer corrosion resistance; also called soft coating; requires protective glazing, except for new silver-free coatings which can face indoors. |

| Thickness Control | Lower precision; cannot produce complex multilayer interference coatings. | High precision; can produce multilayer optical interference coatings. |

| Optical Control | Limited control over solar spectrum; single reflective color. | Flexible solar spectrum control; wide range of adjustable reflective colors. |

| Emissivity | Relatively high (>0.15). | Low (<0.15). |

What does the term ‘surface emissivity’ mean in relation to glass?

📑 Technical vs. Popularized English Versions

| Technical Version | Popularized Version |

|---|---|

| Emissivity, also referred to as hemispherical emissivity, is defined as the ratio of the radiant exitance of a given surface to that of a blackbody at the same temperature, according to the Chinese National Standard Coated Glass—Part 2: Low-emissivity (Low-E) Coated Glass (GB/T 18915.2). | Emissivity, or hemispherical emissivity, describes how much heat energy a surface gives off compared with an ideal blackbody at the same temperature. |

| For glass, surface emissivity is essentially its hemispherical emissivity, representing the ability of the glass surface to re-emit energy outward after reaching thermal equilibrium with absorbed radiation. A lower emissivity means the glass absorbs less radiant energy and subsequently emits less heat. | For glass, surface emissivity tells us how much heat the glass surface absorbs and then re-emits once it reaches balance. The lower the emissivity, the less heat the glass takes in and the less it radiates outward—in simple terms, it keeps more heat from passing through. |

| Conventional glass has a relatively high surface emissivity of about 84% (0.84), whereas the emissivity of the coated surface of Low-E glass is below 15% (0.15). | Ordinary glass has a high surface emissivity of about 84% (0.84), while Low-E glass, thanks to its special coating, has a much lower emissivity of under 15% (0.15). |

Why does Low-E glass improve energy efficiency?

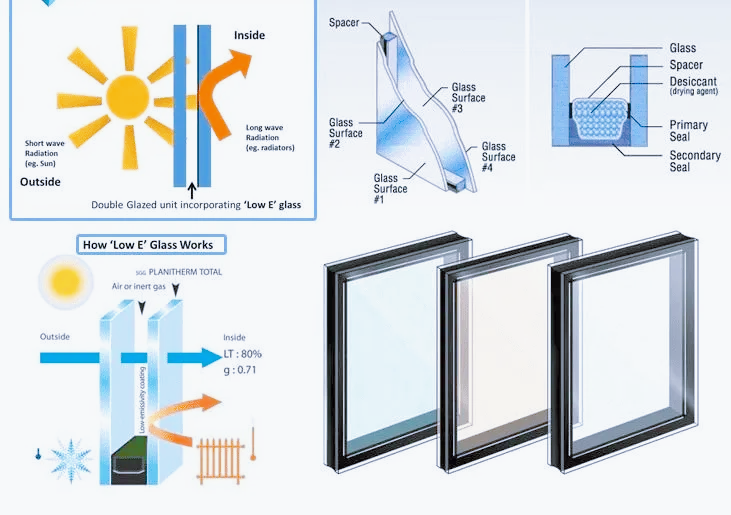

The energy-saving performance of Low-E glass is reflected in two main aspects. First, the Low-E coating reduces heat exchange between the glass surface and the surrounding air, thereby minimizing heat transfer caused by temperature differences across the glass (i.e., conductive heat transfer). This lowers the overall heat flow driven by temperature gradients.

Second, the Low-E coating effectively reflects solar radiation, limiting the amount of radiant heat that passes through the glass (i.e., radiative heat transfer). By reducing both conductive and radiative heat transfer, Low-E glass achieves its energy-saving effect. In practical applications, Low-E glass is typically used in the form of insulated glazing, vacuum glazing, and similar composite structures.

How are emissivity, reflectivity, and transmissivity related?

When external radiation strikes the surface of glass, part of the energy is reflected, part is absorbed, and part is directly transmitted through the glass. According to the law of energy conservation, the sum of these three portions equals the incident radiation energy, which can be expressed as:

Reflectance + Absorptance + Transmittance = 100%

Once thermal equilibrium is reached, the amount of energy absorbed equals the amount re-emitted, leading to the relation:

Absorptance = Emissivity

If transmittance is zero (or very low), then a lower emissivity necessarily implies a higher reflectance. This means that most of the incoming radiation is reflected rather than absorbed.

What forms of thermal energy occur in the natural environment, and what are the characteristics of each?

In the natural environment, there are two main forms of thermal energy relevant to the energy performance of glass: solar radiation and far-infrared radiation.

Solar radiation comes only from outdoors. In addition to visible light, it contains a large amount of infrared heat. For glass, this means that while allowing light transmission, solar heat radiation also passes through into the interior. In summer, this additional heat increases air-conditioning energy consumption, whereas in winter it contributes to indoor heating. Whether and to what extent solar radiation should be restricted depends on the climate zone and the functional use of the building, as specified in building energy efficiency standards.

Far-infrared radiation generally refers to radiation with wavelengths greater than 2.5 μm. Any object with a temperature emits such radiation, and the higher the temperature, the stronger the radiation—hence the greater the sensation of heat (the dashed lines in Figure 1 represent the spectral curves of blackbody radiation at 40 °C and 100 °C). Both indoor and outdoor environments contain far-infrared radiation, but the intensity and balance between indoor and outdoor radiation vary significantly with the seasons.

💬 Contact us via WhatsApp today to get a free consultation for your project. – our team will reply within 24 hours.